A Weather Resilient Approach to Construction – Lessons from Align Joint Venture on HS2

Adverse and seasonal weather conditions have a significant impact on planning and delivering construction activity. Weather affects many aspects of construction, including people, operations, quality, and the environment. This can cause delay, compromise performance and impact safety, as well as the environmental performance of individual sites.

Climate change is already evident in our weather and climate. Future warming will increase weather-related risks. The Main Works Civils Contract (MWCC) for the central section of High Speed Two (HS2) Phase One which includes the Colne Valley Viaduct and Chiltern Tunnels, is being delivered by the Align Integrated Project Team. In this paper, Align share insights and lessons learned from their innovative approach to reduce weather and climate related risks. The approach, which included Artificial Intelligence (AI), management practices, global meteorological data sets and local weather stations proved that more accurate weather predictions can be achieved. It could potentially be applied by clients and contractors on a range of construction sites to improve project outcomes for all parties including improving safety and productivity.

Background and industry context

Infrastructure projects are often built to withstand a 1 in 100-year flood risk. However, as part of its commitment to build a more reliable and climate-resilient railway, HS2 is being built to withstand a 1 in 1,000-year risk. HS2 also has requirements to manage extreme weather during construction – as set out in the HS2 Code of Construction Practice [1]. It states the need for any vulnerable construction related events and activities “to have additional contingency mitigation measures developed and implemented as necessary and appropriate to monitor and manage the effects of extreme weather events and related conditions during construction.”

This paper explores how these requirements translate into the physical construction environment, and illustrates an innovative approach that was taken by Align JV. It recognised the context and challenge of a changing climate, which means that the past is not a reliable indicator of future extreme weather.

Nationally and internationally efforts to predict extreme weather events and the need to develop climate resilient solutions is gaining momentum:

- “Extreme weather is becoming more common due to the effects of climate change. Predicting both the scale and location of these events is a key challenge as they increasingly impact lives, homes, and infrastructure” Duncan Wingham, Executive Chair of Natural Environment Research Council (NERC). [2]

- A forecast from the World Economic Forum [3] put natural disasters and extreme weather events as one of the top three global risks both in the short-term (2 year horizon) and medium-term (10 year horizon).

Adverse weather conditions significantly impact UK construction sites, affecting cost, programme, quality, and safety. Prolonged rainfall and flooding can delay earthworks and increase costs due to site dewatering. High winds and storms disrupt crane operations and external works, leading to programme overruns. Temperature extremes can compromise material performance, such as concrete curing, affecting long-term quality. Additionally, wet or icy conditions heighten the risk of slips, trips, and falls, posing serious safety concerns.

There are a number of challenges for construction in managing weather conditions:

- Financial/commercial barriers – agreeing and delivering mitigations depends on who owns the commercial risk for weather delays. This can be exacerbated by complex supply chains.

- Forecasting accuracy – there can be a limited level of trust in weather forecasting accuracy for planning construction activities beyond a week ahead.

- On site information – there can be limited on-site weather data available, which makes it difficult to analyse opportunities for operational improvement.

- Roles and responsibilities – the allocation of responsibility for managing weather-related risk within operational teams on construction sites can be ambiguously defined.

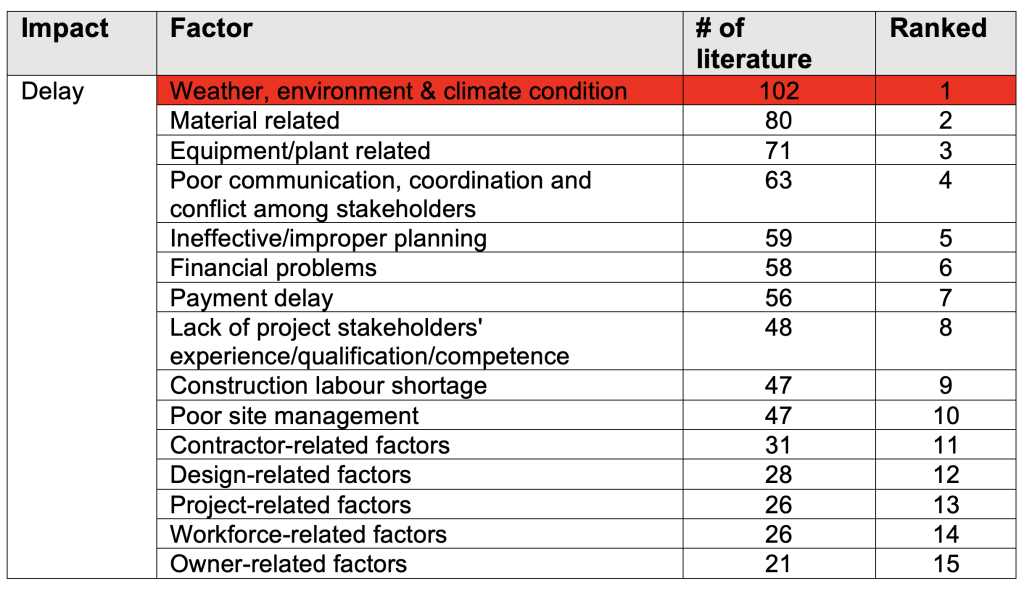

Researchers, Luu and Durdyev, find the weather factor in construction difficult to analyse and so it gets dismissed as “an excusable delay as it is beyond the control of the contractor” [4] or put in a bucket called “exogenous factors” [5]. A wide review of construction, engineering and management research literature investigating causes of delays in construction highlights that weather is the most cited factor, world-wide (Figure 1).

Some research has suggested that improved long-term (greater than 2 years) planning to minimise potential weather-related delays could lead to a 16% reduction in project durations with associated indirect and overhead cost reductions. [6]

When discussing the ability to manage environmental factors such as the weather in construction projects, it is important to recognise the wider system complexities that exist:

Maylor and Turner (2017) Identify three types of complexity. [7]

- Structural complexity – in construction there are interdependencies between construction activities, project functions, supply chain and client. This is then further exacerbated by the variety of construction activity, breadth of scope and multiple construction locations.

- Socio-political complexity – in construction, decision-making, planning, and management processes involve multiple stakeholders. For mega infrastructure projects there can be conflicting interests from government, public and/or private sources.

- Emergent complexity – the construction sector has a developing maturity with technology.

Recent technological development in artificial intelligence (AI) has enabled software developers, using a machine-learning technique called neural networks, to generate weather forecasts faster and more accurately than humans (Figure 2). Neural networks learn from historical weather data and combine this with current worldwide atmospheric data to produce a 10-day ahead forecast. An example of this is Google DeepMind’s GraphCast AI which was evaluated against the world’s leading conventional system for predictions run by the European Centre for Medium-range Weather Forecasts (ECMWF). The AI outperformed ECMWF in 90 percent of the 1,380 metrics. [8]

![Figure 2 – Gartner report on AI capabilities. [9]](https://learninglegacy.hs2.org.uk/wp-content/uploads/2025/09/Figure-2-–-Gartner-report-on-AI-capabilities.jpg)

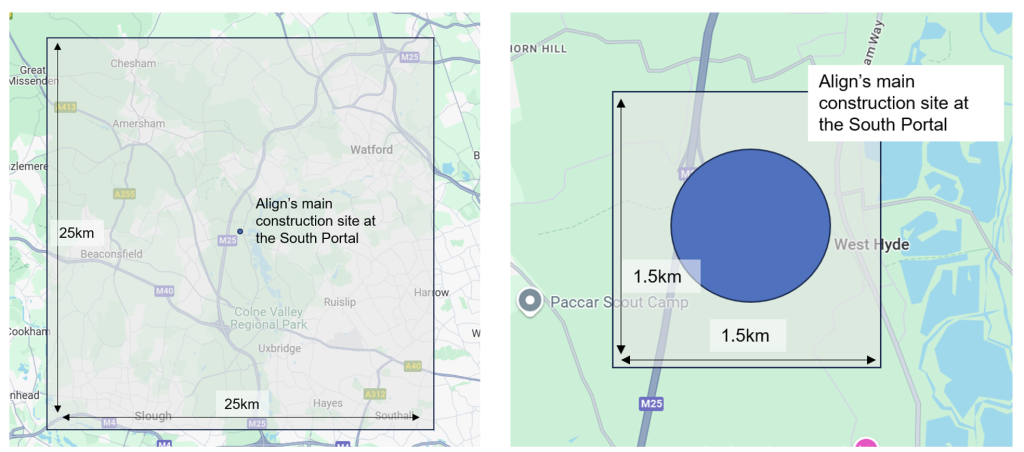

Google DeepMind’s GraphCast model, is an AI model that fully replaces the traditional numerical weather prediction (NWP) models, such as the UK Met Office’s Unified Model. GraphCast does this by learning the relationships between the different variables to predict what will happen next. By focusing on learning the relationships it removes the need to understand the underlying physics and does not have to perform millions of physics calculations each time – making it faster to forecast. The scale of the input data for GraphCast is approximately 0.25 degrees resolution in longitude and latitude. This provides a single weather prediction for an area ~25km² see figure 3 for a basic comparison. These types of models, while faster and more accurate, still do not take into account local factors such as topography, proximity to water bodies, urban heat island effects, local wind patterns, land use and vegetation which are all known to influence weather conditions at a local level.

There is then an unmet need to bridge the gap between the general weather forecast and the weather experienced at a construction site before construction companies can improve their management of the weather risk.

Approach

Align sought to de-risk primary lifting operations for the construction of the Colne Valley Viaduct, a highly weather dependent activity on the critical path for delivery, by seeking an enhanced weather forecasting tool. This tool would support Align’s management by allowing them to optimise downtime. The approach was to work with an innovative start-up company called MetSwift Limited and utilise emerging AI technology for weather forecasting. The aim was to develop a site specific 10-day ahead weather forecasting tool, known as the Short-Term Forecast system (STF), to support construction operations. Once developed the tool would be trialled by the lifting team in the operational environment over a 12-month period.

MetSwift had strong meteorological expertise and had successfully developed worldwide long-range forecasting capabilities for use in the insurance sector and in wind power analysis products but did not have experience in the construction industry or have a tried and tested hyper-local forecasting tool. MetSwift’s idea was to use a long short-term memory (LSTM) network [10] to power their forecast system. This is a form of recurrent neural network (RNN) that is specifically designed to efficiently work with long term time series data, and one which is able to work with data sets containing gaps more effectively than other RNNs. Both of these factors make it especially effective at handling weather forecast data.

MetSwift would work hand in hand with a global NWP model and planned to use their AI engine to identify the relationship between different variables and the subsequent errors in the NWP forecast at Align’s specific construction site. While the underlying NWP model resolution is similar to the training data for GraphCast, by utilising local weather stations, provided by Align, they hoped to teach the model to recognise very local effects. The aspiration was that the AI should then recognise these weather conditions in advance and adjust the underlying NWP forecast to reflect more accurately what is happening on the ground.

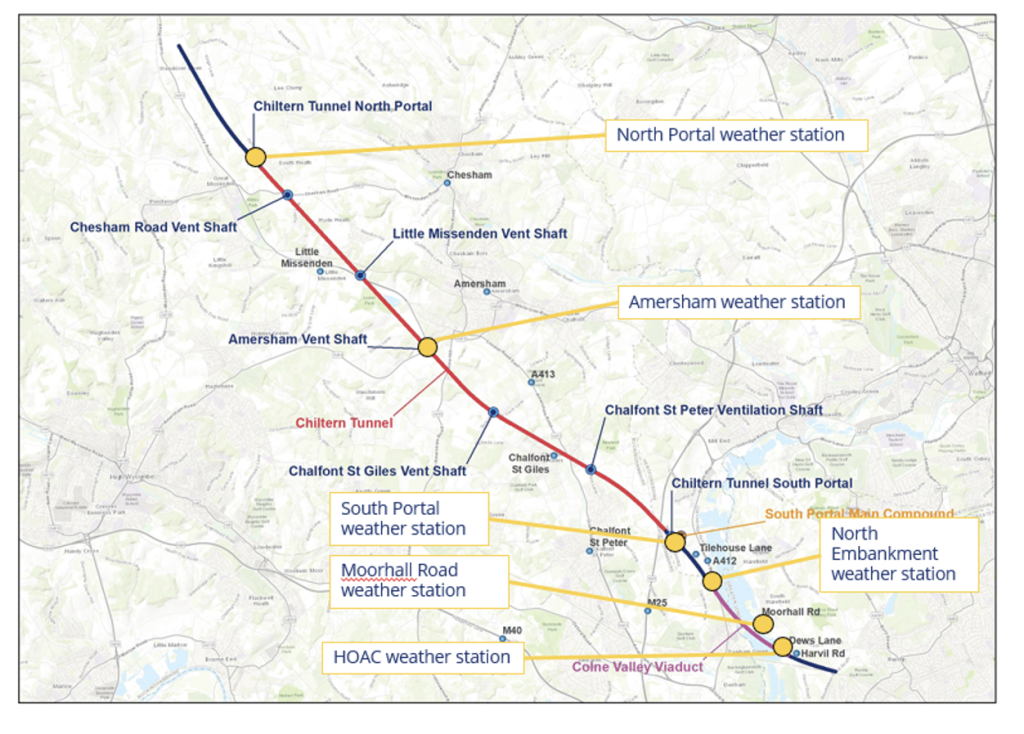

In support of developing this innovation Align purchased and installed six Davis weather instrumentation stations to collect the real-time weather data from key locations across the construction site. Along with the instrumentation, Align had access to a Weather Link Live platform (Figure 4).

To support Align in developing this innovation, seed funding was provided by the HS2 Innovation Team, and it was agreed to run a strategic innovation project between November 2021 to May 2023 to understand the benefits of the capability.

The initial use case for the Proof of Concept (POC) was lifting operations for the installation of one thousand precast segments that make up the 3.4km Colne Valley Viaduct. Align had selected a launch girder as the optimal installation method (Figure 5). This repetitive operation requires segments to be installed in pairs with a target of three pairs installed per 16 hour cycle (Figure 6). Launching the girder between piers is also a critical operation which takes three days. Two key weather limitations on these operations are:

- Starting installation of deck segments is not permitted above gust wind speeds exceed 11.1m/s,

- If lifting has commenced the operation can continue up to gust wind speeds of 20m/s; this is because it is safer to finish the operation than to restart. In this scenario, once the segment has been safely installed the girder must be anchored in and out of service conditions, where wind speeds are expected to exceed 20m/s.

MetSwift collaborated with Align to build their understanding of the lifting operations and weather windows. Over the first three months the prototype STF digital forecasting platform was developed, and the AI tool learnt from the site data provided by the local weather stations. In parallel Align selected early adopters that had critical roles in the viaduct installation operations to trial the tool and provided them with training on the tool. Individuals selected as early adopters included: package managers, shift engineers, appointed persons for lifting and specialist subcontractors. During the trial Align maintained contact with the early adopters through weekly crane coordination meetings which included an opportunity to capture insights and user feedback from the trial. At the end of the trial one-to-one interviews were conducted with key stakeholders to capture qualitative data on the POC.

Align’s approach set out to democratise weather forecasting information to decision-makers at the operational level. Through the STF platform, operational leads for different aspects of the viaduct segment installation could set weather limits (rainfall, wind speed and temperature) for their specific operations. Figure 7 shows a screenshot of the online digital forecasting platform where the user has selected the specific weather parameters, sensitivity and operational window for their activity.

Along with the development of the technology the trial provided a simple one-week lookahead summary forecast for managers to review on a Monday morning which included the anticipated impact of the weather for lifting and earthwork operations. The objective of this weather report was to provide a centralised dataset and improve consistency in decision making.

Outcomes

The outcomes have been separated into two key areas:

People

With weather impacting a wide variety of Align’s civil works it was decided during the trial to widen the scope and increase the number of early adopters. This allowed other teams to test if they could also benefit from the technology. After consulting with other operational teams the trial expanded to include site wide lifting operations, earthworks, water management, commercial, planning and risk functions. Initial uptake of the tool was very good however a few inaccurate forecasts relating to precipitation in the early months of the trial caused some early adopters in the earthworks team to question the usefulness of the tool. In addition to trialling the 10-day ahead app, MetSwift opened up their long-range weather insights platform to Align – enabling other benefits such as:

- Strategic decision making – access to weather predictions for 3 – 24 months ahead provided insights to management for more strategic decisions, as well as supporting long-term look-ahead reviews run by planning teams.

- Segment bonding – assessment of the potential impact from cold weather (below 0°C) on the setting of epoxy resin, a product used in the bonding process for viaduct segments.

- Water management – improved forecasting for site water management which included sedimentation ponds that form part of the slurry treatment plant for tunnelling operations for the Chiltern Tunnels.

Due to a combination of personal habits and the nature of the innovation trial continued use of freely available weather forecasting tools like the Met Office, BBC weather App, XC Weather and AccuWeather could not be stopped. This often meant that the operational teams did not have a single source of the truth for weather data. From a safety point of view the Align Lifting Team often had to do a three-point analysis between the newly developed STF, Met Office and XC Weather to base their planning off the worst-case weather predictions.

During the trial Align staff were briefed on the progress of the POC which led some individuals to seek out opportunities to join the trial or request access the Weather Link Live data. This social contagion effect, experienced by staff wanting to analyse and act upon weather related issues, may have also contributed to Align’s overall project success. The weather data Align collected on site was also used by HS2 for a data hackathon challenge. For the hackathon HS2 brought together business analysts, project delivery experts and data scientists to design a tool to provide real-time insight into weather events to manage decisions and optimise productivity, cost and safety.

In February 2022, a significant weather event Storm Eunice (a 1 in 100-year storm) hit the UK. Using the STF, Align was able to proactively take the decision to close the construction site. This decision was taken 36 hours ahead of the Met Office releasing its red weather alert which was published just 4 hours before the storm hit the UK. This proactive decision improved safety and avoided unnecessary travel and disruption for project staff on the day of the storm.

Technology

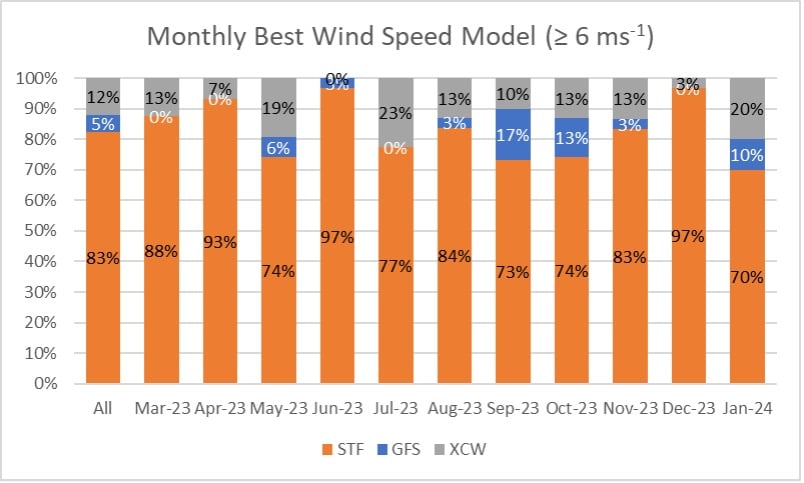

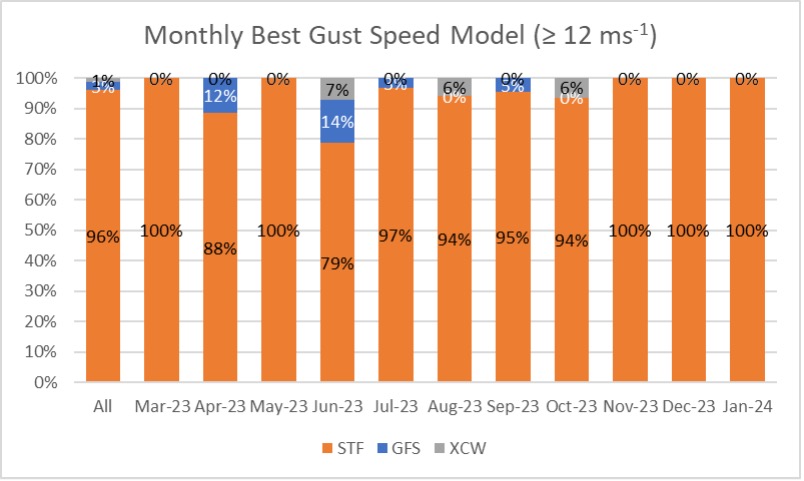

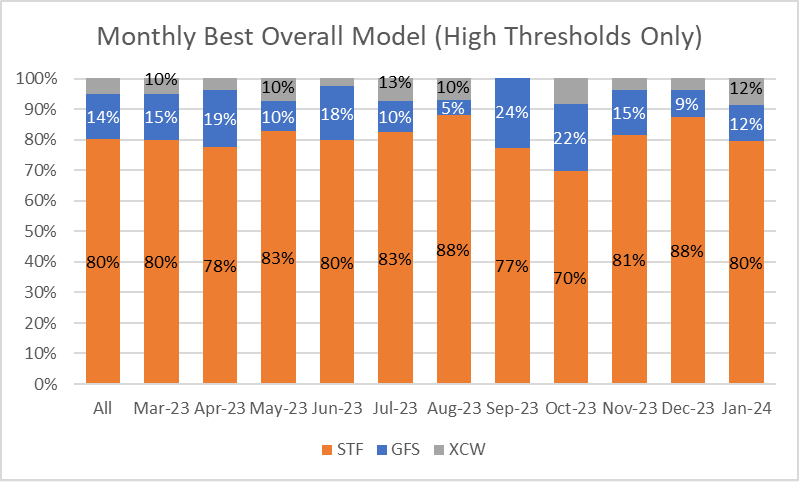

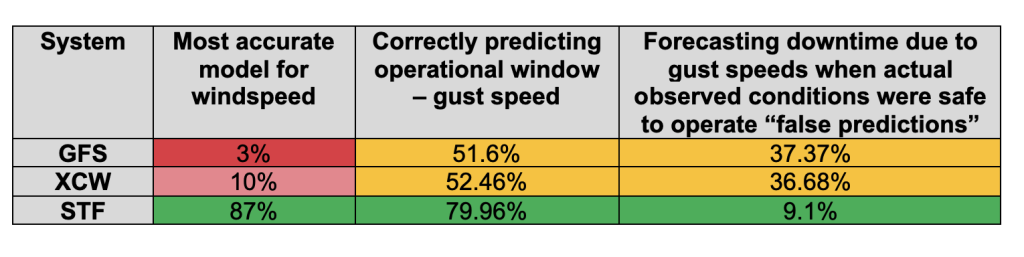

At the end of the trial period, Align committed to continuing with the STF service for another 12-months. To understand the level of accuracy the new technology provided the STF was compared against a traditional NWP model run by the United States’ National Weather Service called the Global Forecast System (GFS) and a freely available weather app called XC Weather (XCW). Figure 8, 9 & 10 below show comparisons of weather forecasts in the 12-months after the trial had concluded. These charts quantify which system gave the most accurate weather forecast data when compared with what was actually observed on site, as recorded from the Davis weather stations. The third chart includes all weather data; wind, gust, rainfall, and temperature. The SFT model was consistently the most accurate across all seasons.

Learnings and Recommendations

The approach, which included Artificial Intelligence (AI), management practices, global meteorological data sets and local weather stations proved that more accurate weather predictions can be achieved and can be applied by clients and contractors for construction sites to improve project outcomes for all parties.

Over the last three years Align’s Lifting Team have been responsible for more than 100 lifting assets and have overseen ~2.3 million operational lifts. On average the Head of Lifting has intervened and proactively stopped lifting operations 8 times a year due to adverse weather conditions with the support of the STF platform. Had he relied solely on the existing technology with the more general weather forecast, lifting operations may have been stopped another one to two days per year – which would obviously have an impact on site productivity.

The learnings from the trial include:

People

- The technology was perceived as a value-adding capability for the Align project team as demonstrated by the commitment to continue with the service for a further year.

- Releasing the POC after three months of training the algorithms may have been too soon as it led to some inaccurate precipitation predictions. Improvements to the algorithm to correct a bias not to predict zero rainfall along with ingesting more site weather data allowed the tool to became more accurate at predicting precipitation towards the end of the trial. However this did not materially impact decisions made in the Lifting Team which was the main focus of for trialling the technology.

- Even without the STF platform installing the Davis weather stations and allowing staff access to Weather Link Live data created a positive change and enabled data drive decisions.

- The democratisation of the STF App had mixed results. Without mandating a single source of the truth for weather forecasting some users fell back to old habits and used weather apps that were more familiar to them. Some process owners saw the new weather data as a nice to have but did not hardwire it into their decision-making approach.

- While Align’s Head of Lifting built confidence in the system for critical operations allowing for early project interventions, he still had to use the three-point analysis due to fear of false negatives.

- It proved difficult to capture the financial benefit the STF had for the plethora of operational decisions that take place daily on mega infrastructure construction sites.

Technology

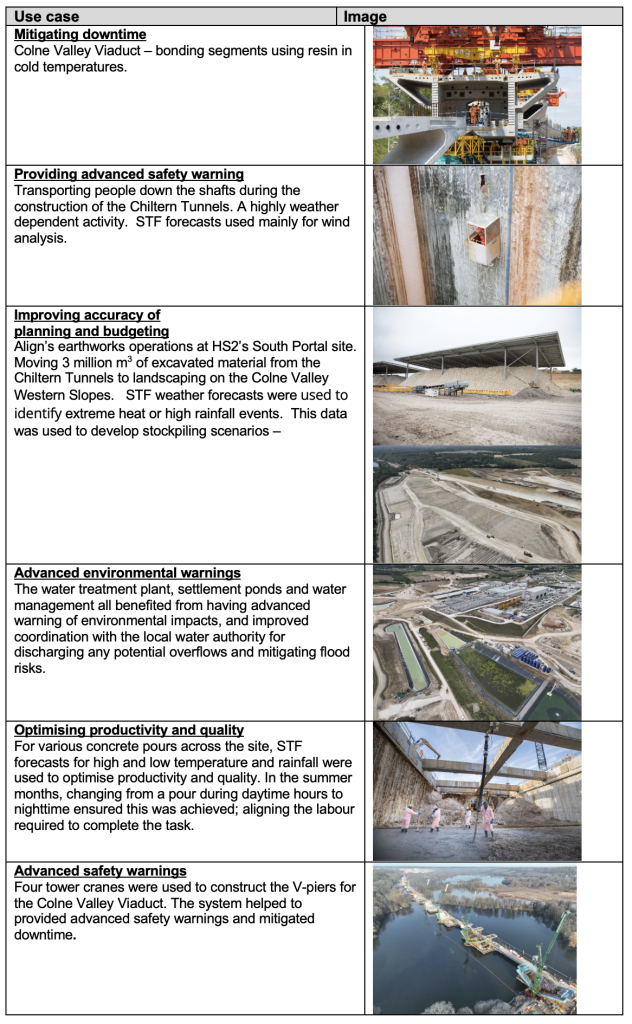

The STF was successfully used to improve management decisions and operational outcomes in a number of use cases, including lifting operations, earthworks, water management and safety (See Figure 11 for a full list of use cases).

Figure 12 below shows the operational significance of using the new STF system over the alternatives. In summary:

- Column 2 shows that the STF was the most accurate at forecasting on site windspeeds.

- Column 3 shows the STF had a significant gain when compared to the alternatives, at correctly predicting safe operational windows on site.

- Column 4 shows that the STF was better at not falsely predicting periods of downtime, giving a 20% greater window of operation than if the alternatives were used to plan lifting operations on-site. If this technology was to be applied across the HS2 programme with similar benefits there is an opportunity for a multi-million pound operational improvement.

- Where the STF became very useful was providing quantified wind speeds for new weather fronts.

Wider benefits

While the focus of this Learning Legacy has been on the benefits to Capital Expenditure, this type of technology can also play a role during the operation life of the asset. Network Rail stated that: Between 2006/07 and 2020/21, weather related incidents caused 322,000+ delay events, 26+ million delay minutes and +£1 billion of operational compensation payments [11]. If the innovation was scaled-up and contractors collected years of local weather data along the HS2 route during construction this bank of hyper local conditions could enable a more informed maintenance regime.

The trial with Align and MetSwift supported HS2’s strategic innovation intent to build a legacy of knowledge, expertise and new commercial opportunities for the UK. This project has driven innovation into the programme by developing new technology and services while supporting a UK SME.

Recommendations

The construction industry has a number of culturally accepted norms such as low productivity, cost overruns, late delivery and poor quality as highlighted by successive reports such as the 1998 Egan Report [12], 2016 Farmer Review [13] and 2021 Office for National Statistics investigation [14]. By paying closer attention to weather, construction organisations and clients have the opportunity to improve delivery. A paradigm shift is arguably required to move project estimating and scheduling for weather to a predictable and value add activity improving project outcomes.

It is recommended that construction projects develop a coherent weather strategy that includes:

- Connecting environmental, operational, and commercial data architecture across the project to ensure there is the correct basis for decision making and information flows.

- Considering suitable forms of weather forecasting, including making a conscious decision to assess if defaulting to the nearest Met Office weather station is appropriate and will provide the level of accuracy needed. For Align’s requirements it was not sufficient.

- Embedding these innovative technologies into project ways of working on a project. For instance, this could include:

- Formally bringing a long-range forecasting capability into the risk and planning domain in support of the Quantitative Schedule Risk Analysis (QRSA) process to enhance data driven decision making and remove optimism bias.

- Supporting a common data environment by linking real-time weather to other systems e.g. plant telematics platform to create deeper insights on downtime and idling offers further opportunities to optimise productivity and saving cost and carbon.

- Linking the data from crane anemometers to the overall weather dataset to improve forecasting predictions.

- Using site diaries as a method of recording the daily operational decisions linked to the STF data to quantify individual improvements.

Overall, it is recommended that clients and contractors harness this cutting-edge technology by considering a more collaborative approach to managing weather. Historically, profit margins for some construction companies can be low, a 2021 Turner and Townsend market survey highlighted the UK average profit margin for construction was 3.9% [15], leading to a reluctance by some to invest in new disruptive technology like the STF. Climate resilience is a shared responsibility, and it is recommended that a cost sharing mechanism should be considered for procuring this technology on future projects.

Using this technology to be more informed during contract negotiations between clients and contractors when pricing and accepting weather risk should result in more realistic construction programmes. This collaborative advantage extends beyond the immediate relationship of client and contractor into the supply chain, with ongoing use of the technology during construction arguably delivering better project outcomes for all.

Insurance companies are using this technology to improve their understanding of weather risk and pricing for specific insurance products. It is recommended that as well as collaborating with each other, clients and contractors should engage their insurers in discussions when seeking to deploy this technology. Delivering construction projects in a more climate resilient manner has the potential to reduce Contractor All Risk (CAR) policies.

This type of technology continues to evolve at pace and in October 2023, as Align concluded on its small innovation trial, it was announced publicly that the UK Met Office would develop its own AI weather forecasting capability. In collaborating with the Alan Turing Institute, Britain’s centre for AI research, the Met Office will incorporate AI weather forecasting into its existing supercomputer infrastructure [16]. The number of products providing weather insights is expanding from both big-tech companies and start-ups looking to use the latest generative AI tools. Clients and contractors may not have the in-house capabilities in meteorology or data science to be able to assess the strengths and weaknesses of this technology. It is recommended that an industry lead innovation project be established to assess the relative merits of the market leading products.

Conclusion

In large infrastructure projects, such as roads, railways, airports, and water facilities, risk and uncertainty often leads to the avoidance of innovation as clients and contractors seek to minimise risks. Climate change adds another level of uncertainty to constructing mega infrastructure. This paper sets out how the advent of big data and evolving AI technology for weather forecasting offers clients and contractors an opportunity to reduce uncertainty during construction which can also be apply to operational assets.

This collaborative innovation was a step toward wider acceptance of the value of this technology. Align’s JV partners and HS2 are continuing to explore opportunities for the deployment of this type of technology on their projects.

Acknowledgements

David Hall, Head of Lifting, Align JV & Sir Robert McAlpine

Joseph France, Head Data Scientist, MetSwift Ltd

References

- HS2. High Speed Rail (London-West Midlands) Environmental Minimum Requirements. Annex 1: Code of Construction Practice. 2017. Department for Transport

- UK Research and Innovation. UK scientists to improve forecasting of extreme weather events [Internet]. 2023. [cited 2024 February 20]. Available from: https://www.ukri.org/news/uk-scientists-to-improve-forecasting-of-extreme-weather-events/#:~:text=Duncan%20Wingham%2C%20Executive%20Chair%20of,impact%20lives%2C%20homes%20and%20infrastructure.

- World Economic Forum. The Global Risks Report 2023 18th Edition insight report. [internet]. 2023. [cited 2023 December 14]. Available from: https://www.weforum.org/publications/global-risks-report-2023/

- Durdyev S and Hosseini M. Causes of delays on construction projects: a comprehensive list. IJMPB. 2018 Dec 29; 13(1):27.

- Luu V, Kim S, Tuan N and Ogunlana S. Quantifying schedule risk in construction projects using Bayesian belief networks. IPMA. 2008 Mar 04; 27(2009):40.

- Ballesteros-Perez P, Smith ST, Lloyd-Papworth J and Cooke P. Incorporating the effect of weather in construction scheduling and management with sine wave curves: application in the United Kingdom. Construction Management and Economics. 2018; 36;12: 666–682.

- Maylor H and Turner N. Understand, Reduce, Respond: Project Complexity Management Theory and Practice. International Journal of Operations and Production Management. 2017 Aug 07; 37(8): 1076-1093.

- Lam R, Sanchez-Gonzlez A, Willson M, Wirnsberger P, Fortunato M, Alet F, et al. Learning skilful medium-range global weather forecasting. Science. 2023 Nov 14; 382(6677):1416-1421.

- Gartner Inc. Think again: How AI unlocks human potential [internet]. 2023. [cited 2023, Oct, 18]. Available from:https://www.gartner.com/en/experts/think-again-series/ai-unlocks-human-potential?utm_campaign=SM_GB_YOY_GTR_SOC_SF1_SM-BRAND-THINKAGAIN-EP3&utm_content=Gartner&utm_medium=social&utm_source=linkedin&utm_term=Function:+Cross+Functional,Level+6:+Copy/creative+provided+with+social+input,Media:+CCOE+Created+Card,Media:+Data,MT+Brand,ST+-+Brand:+Think+Again

- Sherstinsky A. Fundamentals of Recurrent Neural Network (RNN) and Long Short-Term Memory (LSTM) network. Physica D: Nonlinear Phenomena. 2020 Mar; 01;404.

- Network Rail. Network Rail Third Adaptation Report. [internet]. 2021. [cited 2023 Sep 17]. Available from: https://www.networkrail.co.uk/wp-content/uploads/2022/01/Network-Rail-Third-Adaptation-Report-December-2021.pdf .

- Egan J. Rethinking Construction: Report of the Construction Task Force. 1998. Department of Trade and Industry. HMSO.

- Farmer M. The Framer Review of the UK Construction Labour Model. 2016 UK Construction Leadership Council.

- Office for National Statistics. Productivity in the construction industry, UK: 2021. 2021.

- Turner and Townsend International Construction Market Survey 2021

- Met Office. Met office data science framework [internet]. [cited 2023 Sep 19]. Available from: https://www.metoffice.gov.uk/research/foundation/informatics-lab/met-office-data-science-framework#:~:text=The%20Met%20Office%20Data%20Science,Capabilities.

Supporting Materials

MetSwift Accuracy Study vs Climatology

MetSwift. Company News [internet]. UK: Peacock J. [Updated 2022 May 17; cited 2022 Aug 23]. Available from: https://www.metswift.com/blog/accurate-long-range-wind-warning-gives-align-jv-time-to-go-into-safe-mode-with-cranes