Alternative fuels and additives in construction

As part of High Speed Two (HS2)’s Innovation programme, a trial of alternative fuels was carried out in partnership with the Centre for Low Emission Construction at Imperial College London and the Main Works Civils Contractor at their HS2 construction site near Coventry in April 2021. The trial measured tail-pipe emissions to determine the potential emission savings of using alternative fuels when compared to red diesel.

The ‘real-world’ emission measurement tests were carried out on two 20-tonne excavators – a Liebherr R920 compact excavator (Stage IIIB) and a Komatsu PC210 excavator

(Stage IV). The fuels tested included standard red diesel (EN590) to provide a baseline for comparative purposes, red diesel with F18 fuel additive and two biofuels – Hydrogenated Vegetable Oil (HVO) and Enhanced HVO.

While the results showed limited air quality benefits when compared to red diesel, the trial highlighted the potential carbon reduction opportunities through the sustainable sourcing of alternative fuels, for example fuels derived from wastes or crops rather than from fossil fuels.

Both machines used during the trial had exhaust gas after-treatment technology installed to reduce nitrogen dioxide and particle emissions. As such the study also recognises that older machines with no after-treatment technology may have a greater potential for reducing emissions through the use of alternative fuels.

Further studies, across the construction industry, are underway to better understand alternative fuels, and where the use of alternative fuels has the biggest emission saving potential.

Notation

CO Carbon monoxide

CO2 Carbon dioxide

CO2e Carbon dioxide equivalent

Introduction

Air quality is important for human health, wellbeing, and the environment. The World Health Organisation (WHO) highlights air pollution as being annually responsible for about one in every nine deaths[1]. As air pollution continues to rise at alarming rates, it is seen as the biggest environmental risk to health, and is emphasised as a public health emergency affecting economies as well as quality of life[1].

The National Atmospheric Emissions Inventory (NAEI) highlights the construction industry as a key source of air pollutants across the United Kingdom, with exhaust emissions from Non- Road Mobile Machinery (NRMM) as a significant contributor[2].

NRMM is defined as any mobile machine, transportable equipment or vehicle, with or without bodywork or wheels, not intended for the transport of passengers or goods on roads, and includes machinery installed on the chassis of vehicles intended for the transport of passengers on roads[3]. Emissions from engines in these machines are regulated under Regulation (EU) 2016/1628 in Europe[3].

The High Speed Two (HS2) Air Quality Strategy aims to avoid emissions, but where this is not possible, sets key requirements to ensure emissions are reduced through control measures so that public and workforce exposure is minimised[4]. While HS2 is ensuring all works are undertaken following Best Practical Means in reducing emissions it is important to continually ensure that these measures are effective through management, monitoring and mitigating against potential emissions, as outlined in the HS2 Code of Construction Practice (CoCP)[5].

As part of HS2’s Innovation programme, a trial of alternative fuels was carried out in partnership with the Centre for Low Emission Construction (CLEC) at Imperial College London and the Main Works Civils Contractor – Balfour Beatty VINCI (BBV) – to determine the potential emission savings of using alternative fuels when compared to red diesel.

Renewable fuels

Within the construction sector, there is a significant reliance on diesel to meet energy demands. As diesel is a fossil fuel derived product and it therefore has the potential to significantly impact on the ability to meet the United Kingdom’s net zero emission commitments by 2050.

In the UK Government’s Net Zero Strategy: Build Back Greener, NRMM is noted as accounting for around 12MTCO2e per year[6]. It is therefore integral that solutions to reduce the reliance of NRMM on red diesel are prioritised and studies to ensure detailed understandings in alternative solutions is gained.

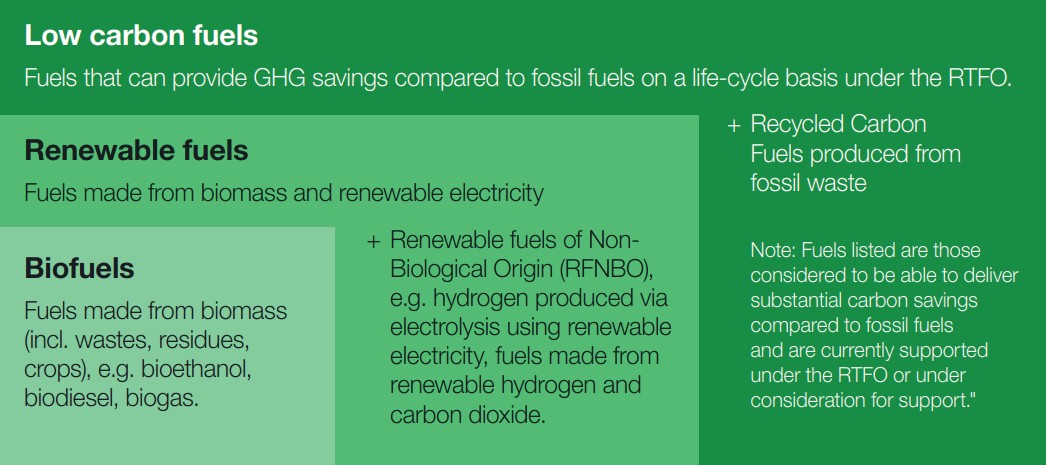

The Renewable Transport Fuel Obligation (RTFO) supports the UK policy on decarbonising transport and NRMM by encouraging the production and use of renewable fuels that do not damage the environment[7]. Figure 1 is extracted from the Department for Transport’ Decarbonising Transport Strategy defining the key differences between low carbon fuels, renewable fuels and biofuels.

Trial

As part of the HS2 innovation programme, an independent trial to assess the real-world impacts of using alternative fuels in construction plant was undertaken. The trial focused on confirming whether the use of these alternative fuels, when compared to red diesel, could reduce emissions and improve local air quality.

Two 20T excavators deployed by BBV, at an HS2 construction site near Coventry in April 2021, were used to test three alternative fuels compared to red diesel, including:

- F18, a fuel additive,

- Hydrogenated Vegetable Oil (HVO), and

- An enhanced HVO, Green D+.

A test cycle was designed to replicate real world activity and allow for repeatability across all tests. Emission testing was carried out by the CLEC at Imperial Collage London.

Methodology

The two 20-tonne excavators used in the trial included a Liebherr R920 compact (Figure 2) and Komatsu PC210 (Figure 3). The technical specifications for both machines are shown in Table 1.

Table 1. Technical specifications of the machines

| Parameter | Liebhrr R920 | Komatsu PC210 |

|---|---|---|

|

Rated Power |

110kW @ 1800rpm |

123kW @ 2000rpm |

|

NRMM Type |

Tracked excavator |

Tracked excavator |

|

Emission Standard |

Stage IIIB |

Stage IV |

|

Engine Production date |

2018 |

2018 |

|

Operational hours |

4290 |

5380 |

|

Engine displacement |

4.5 litre |

6.7 litre |

|

After-treatment |

SCR |

EGR, DOC, DFP, SCR |

To inhibit the possible influence of driver variability, the same operator was used for all tests across both machines. Both machines performed the same work activities including – machine idle, machine tracking, digging, and backfill-grading following the same route and working in the same area of an aggregate stockpile. Each activity was performed for a minimum period of 15-minutes each, forming a 1-hour test run. The test run was repeated three times.

Three different types of fuels were compared with industry standard red diesel (EN590), which was also tested to generate a baseline scenario. The fuel tank was fully drained, and new fuel filters fitted before the machine was filled with the next fuel to be tested. To ensure a complete purge of the fuel delivery system, the machine was operated for a couple of hours before the next test procedure was carried out.

A 3DATX parSYNC® integrated portable emissions measurement system (iPEMS) was used to measure the carbon monoxide (CO), carbon dioxide (CO2), nitrogen monoxide (NO), nitrogen dioxide (NO2), particle mass (PM), and particle number (PN) concentrations in the exhaust, using a sample probe mounted inside the tailpipe. A flowmeter was connected to the tailpipe of the Komatsu PC210 excavator, to measure the exhaust mass flow. There was insufficient space on the back of the Liebherr R920 compact excavator to mount the flowmeter, and due to safety issues regarding access and working at height, the flowmeter was not used.

Engine speed, fuel rate, estimated power, intake air temperature and intake air pressure were recorded from the engine CANbus port using proprietary engine diagnostic software (provided and logged independently by Liebherr and Komatsu engineers). These parameters were subsequently time-aligned with the measured emissions data and used to convert the measured concentrations to mass-based values, to allow for direct comparison with the EU emission standards.

Results

The results indicated that when used in the Stage IIIB Liebherr R920 excavator, the alternative fuels reduced CO2, NOx, PM and PN emissions when compared to red diesel.

In contrast the Stage IV Komatsu PC210 excavator, which had a Selective Catalytic Reduction (SCR) exhaust after-treatment system showed reductions in PM and PN but no CO2 improvement, as well as significantly higher NOx emissions. During idling, NOx emissions were found to be up 100 times higher when compared to that of red diesel, due to low exhaust gas temperatures not activating the SCR exhaust after-treatment system.

Although emissions reductions were evident, none of the alternative fuels tested were found to conclusively reduce all emissions on both excavators and in some cases, an increase in emissions was evident.

Furthermore, both machines used during the trial had exhaust gas after-treatment technology installed to reduce nitrogen dioxide and particle emissions. As such the study recognises that older machines with no after-treatment technology may have a greater potential for reducing emissions through the use of alternative fuels.

While the study shows minimal reductions in tailpipe emissions, it is noted that carbon saving opportunities through the use of alternative fuels do exist through sustainable sourcing, i.e. using fuels that are not fossil fuel derived, but rather produced through waste materials or crops. This study, however, has not undertaken an analysis of the full lifecycle of the fuels, but rather was aimed at quantifying tailpipe emission saving potentials.

The full results are published in the Centre for Low Emission Construction report HS2 BBV alternative fuel trial[9].

Conclusion

While the results of the trial indicated limited air quality benefits when compared to red diesel, the trial highlighted the potential carbon reduction opportunities through the sustainable sourcing of alternative fuels, for example fuels derived from wastes or crops rather than from fossil fuels.

With the construction industry being a key source of air pollutants within the UK, and the significant reliance the industry has on diesel it is paramount that diesel alternative solutions continue to be trialled and tested with the objective of supporting the UK’s net zero emission commitments by 2050.

Further studies, across the construction industry, are underway to better understand alternative fuels, and where the use of alternative fuels has the biggest emission saving potential through both use and sourcing. Alternative fuels have a key role in decarbonising the construction industry. As majority of these fuels are drop-in alternatives to diesel, they play a key role in the move towards diesel-free construction, aimed at reducing impacts associated with construction activities on surrounding communities.

Implementation on HS2

The large majority of contractors working on HS2 currently making use of alternative fuels, which has, to date, resulted in between 85-90% carbon saving through sustainable sourcing and the reduced use of diesel. Alternative fuels, including those tested during the trial, play a key role in meeting the HS2 net-zero carbon plan[10] commitments of diesel-free construction sites by 2029, delivering the first diesel-free construction site in 2022. As a drop-in fuel, these bio-fuels and additives provide an easier first-step transition from full reliance on diesel.

Following the trial, HS2 has recommended to all contractors working on the project, that where biofuels are being used, that they are in line with the definitions outlined in the RTFO, which regulates biofuels used for transport and non-road mobile machinery.

Furthermore, HS2 recommends that contractors ensure that the biofuel providers are registered with recognised assurance schemes such as the Zemo Partnership Renewable Fuels Assurance Scheme1 to ensure due diligence is undertaken around the potential greenhouse gas emission savings through sustainable sourcing.

Acknowledgments

Balfour Beatty Plant and Fleet Hire

Bekir Andrews – former Sustainability Director at Balfour Beatty Jake Walker – Mechanical Project Engineer (Balfour Beatty Vinci)

References

1. World Health Organisation (2016). Ambient air pollution: A global assessment of exposure and burden of disease. Geneva: WHO document production.

2. National Atmospheric Emissions Inventory (2019). Department for Business, Energy & Industrial Strategy.

3. Parliament E. (2016) Regulation 2016/1628 on requirements relating to gaseous and particulate pollutant emission limits and type-approval for internal combustion engines for non-road mobile machinery. In: Parliament E, editor.: Official Journal of the European Union; 2016. p. 65.

4. High Speed 2 Limited (2017) Air Quality Strategy.

5. High Speed 2 Limited (2017) Environmental Minimum Requirement Annex 1: Code of Construction Practice.

6. HM Government (2021). Net Zero Strategy: Build Back Greener. Department for Business, Energy & Industrial Strategy

7. Department for Transport (2021). Renewable Transport Fuel Obligation (RTFO) guidance: 2021.

8. Department for Transport (2021). Decarbonising Transport: A Better, Greener Britain.

9. Marsh, D. and Desouza, C. (2021) HS2 BBV alternative fuel trial. Centre for Low Emission Construction,

10. High Speed 2 Limited. (2022) Net Zero Carbon Plan: A cleaner, greener future.

Peer review

- Mike deSilvaHS2 Ltd

- Mike WhiteHS2 Ltd