BBV’s carbon reduction journey towards the 50% reduction target

Balfour Beatty VINCI Joint Venture (BBV) is contributing to the “cleaner, greener future” in High Speed 2 (HS2)’s Net Zero Carbon Plan by striving to reach a 50% reduction compared to the 4,148,208 tCO2e baseline – currently having reached -43.4%. To map this journey, BBV uses the PAS2080 framework and assesses its whole life carbon footprint six-monthly to track progress in near time.

This paper will outline the steps taken to embed carbon leadership across the project, steering decarbonisation at an asset level across key design stages and construction processes. It will also discuss the opportunities and challenges of managing carbon reduction on a major infrastructure project.

It is aimed at environmental teams aiming to manage carbon and its reduction on complex projects but would benefit anyone wanting to widen their understanding of carbon management.

Background and industry context

The rising accumulation of greenhouse gases (GHG) in the atmosphere and consequent climate change is posing an increasing threat to societies all over the world. In June 2019, the UK Parliament passed legislation requiring the government to reduce the UK’s net emissions of greenhouse gases by 100% relative to 1990 levels by 2050 [1]. This would keep the UK in line with the 2015 Paris Agreement (COP21), where countries agreed to cut greenhouse gas emissions with a view to ‘holding the increase in the global average temperature to well below 2°C above pre-industrial levels and pursuing efforts to limit the temperature increase to 1.5°C above pre-industrial levels.

Addressing greenhouse gas emissions and the resulting climate change is a major responsibility of the infrastructure and transportation sectors. In the UK, construction activity generates about 50 million tonnes of CO2 emissions annually, of which more than half are related to the production of building products and materials, especially steel and cement, which contribute approximately 15% of the world’s carbon emissions [2]. Consequently, there is an increasing need for the transportation and civil engineering sectors to address the implications of transportation infrastructure design and construction.

Aligned with the UK Net Zero Strategy to tackle climate change and UK Government guidance on promoting net zero carbon and sustainability in construction [3], High Speed Two (HS2), Britian’s biggest infrastructure project, plays a significant role in supporting the reduction of carbon emissions. HS2 is built on a strong environmental sustainability vision aiming to avoid, reduce and mitigate impacts as much as possible across 14 topic disciplines covered in the Environmental Statement[4]:

- Agriculture, forestry and soils

- Air quality

- Climate

- Community

- Cultural heritage

- Ecology

- Electromagnetic interference

- Land quality

- Landscape and visual assessment

- Socio-economics

- Sound, noise and vibration

- Traffic and transport

- Waste,

- Water resources

Carbon and biodiversity were identified as the two key drivers of this vision. Therefore, HS2 set a highly ambitious Net Zero target in 2035 (against 2050 UK target). To ensure this is reached, a supporting target of 50% carbon reduction compared to the agreed baseline was set to all Main Works Civils Contractors (MWCC).

Balfour Beatty Vinci (BBV) is the Main Works Civils Contractor (MWCC) for the northern section of HS2 Phase One (also referred to as Area North) including Long Itchington Wood Green Tunnel to Delta Junction and Birmingham Spur and the Delta Junction to the West Coast Main Line (WCML) tie-in.

BBV in collaboration with the Design Joint Venture (DJV) carbon team has been assessing the carbon footprint of the design phases, process and strategies changes aiming to reach the 50% route wide reduction.

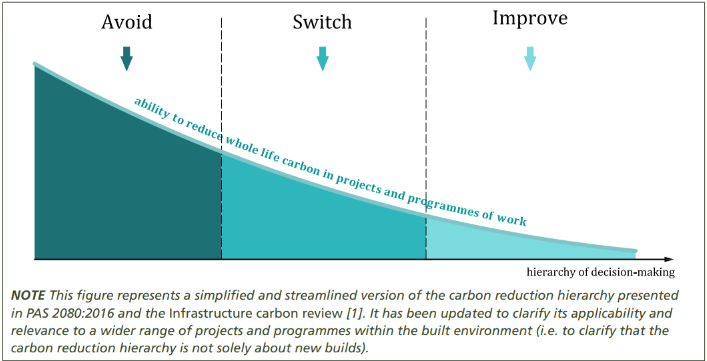

To drive this carbon reduction in all stages of the project delivery, BBV is using the PAS2080: 2023 “Carbon Management in Buildings and Infrastructure” Standard [5]. This standard articulates the client-contractor-user interactions during all phases of project life. It also concentrates on four key aspects of the carbon reduction potential: Build nothing, Build less, Build clever and Build efficiently (see Figure 1).

Avoid– HS2 is deemed a necessary project and the planning phase ended when the Hybrid Bill was enacted in 2017.

Switch – the design phase has the highest opportunity for carbon reduction after the planning phase, when “build less” could be adopted (e.g. maximising the use of existing assets).

Improve – as the project organically moves to an increase in construction activities, opportunities for building cleverly and efficiently arise.

This paper will highlight some of the key steps of the process adopted by BBV.

Approach

Baseline

A baseline is necessary to track any carbon reduction journey, and was established using the initial design, exemplar assets, and industry averages. A lifecycle assessment (LCA) is now carried out 6-monthly to monitor progress across the design phases and reach the 50% carbon reduction target set by HS2.

Methodology

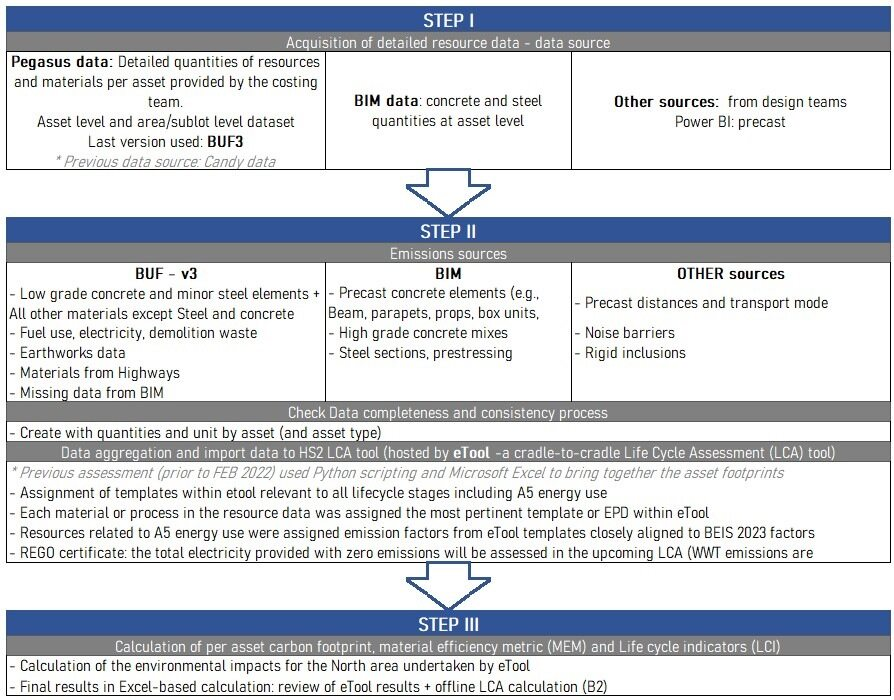

Throughout the process of assessing the carbon footprint of the key project gateway – from baseline to Consolidation and Detailed Design – the dataset sources from cost forecast, BIM (Building Information Modelling) models and design teams follow a check process. In line with the HS2 Technical Standard on Carbon footprinting and life cycle assessment[7], all inputs for which quantifiable data is available are included in the carbon assessment.

Three main steps, illustrated in the Figure 2, summarise the process undertaken to update the carbon assessment.

When acquiring the data from the different sources (step I), the checks taken enables the identification of potential missing or erroneous data (step II). For instance, BIM data preparation steps involve checks on:

- asset name and Unique Asset Identifier (UAID)

- suitability status

- duplicated volumes

- completeness and consistency of quantities compared to the previous BIM data provided

- simplification of the data to match the format of the previous assessments, divided into Lots and asset type

After checking and confirming the assumptions to be adopted, the data from the sources is imported into the HS2 LCA tool (eTool) and associated with a predefined template.

The final step (Step III) consists of calculating the environmental impact for the project and completing the process with offline calculations on maintenance (B2).

eTool has been required by HS2 to carry out the environmental assessment, this tool is a cradle-to-cradle LCA tool that looks at the whole lifecycle of the design to assess the full environmental impacts of design and construction decisions. The tool is compliant with BS EN ISO 14040, BS EN ISO 14044, BS EN 15978 and PAS2080[6][8][9][10].

eTool has been required by HS2 to carry out the environmental assessment, this tool is a cradle-to-cradle LCA tool that looks at the whole lifecycle of the design to assess the full environmental impacts of design and construction decisions. The tool is compliant with BS EN ISO 14040, BS EN ISO 14044, BS EN 15978 and PAS2080.

Identifying the carbon reduction opportunities

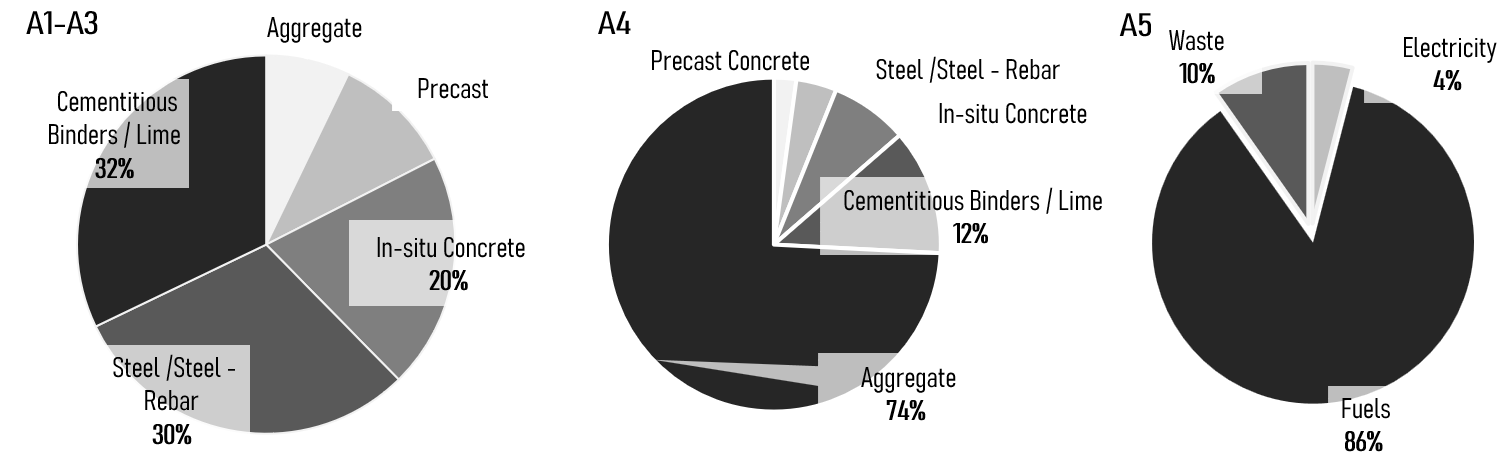

In the following paragraphs, the paper presents the lifecycle emission stages, which are named in a codified way. A1-A3 represents the cradle to gate emissions, sometimes also called the embodied emissions in the product, A4 represents the transport to and from site, A5 is the construction and installation activities. B1-B7 represent the use stage, with the maintenance, operating energy and water, replacement of items.

Focusing on the results, embodied carbon emissions from A1-A3 contribute more than 50% of the carbon emissions throughout the HS2 project life cycle, followed by the construction stage (A5) with around 25% and transport to site (A4) with 17%. Concrete, cementitious materials and steel appear as having the highest impact for A1-A3 (Figure 3).

Considering the areas of highest carbon footprint first has enabled Area North teams to concentrate efforts where impactful reductions would occur.

Ad-hoc multidisciplinary workshops have been a gateway to identifying sustainability opportunities, assign owners and track progress. These workshops used to take place for carbon and resources separately, however they were recently merged to improve information flow. Most resources savings will decrease carbon, and vice-versa. Opportunities identified included:

- HS2 wide actions, such as considering the potential for reuse of compounds by rail systems,

- Area North wide actions, such as decreasing the percentage of lime used in soil stabilisation,

- Sublot wide actions, such as the use of conveyor belts where appropriate to move material,

- Asset-specific actions, such as using pre-cast concrete elements.

A Resources and Carbon Opportunities Register was used to capture these sustainability opportunities. However, we will detail in the Learning and Recommendations sections how that register could be better managed.

Procurement

The largest life cycle module of BBV’s LCA is the product stage at 53%. Reducing embodied carbon impacts arising from the project life span – including raw material sourcing, manufacture, use, and disposal of construction products – is a critical element in reducing BBV’s overall carbon impact.

Life Cycle Costing is where appropriate in the selection of alternatives that impact both pending and future costs. Specific themes that may be challenged through the tender process include maintenance costs, energy usage, water usage, durability / life span, and/or disposal costs (where applicable). These specific areas are challenged through our tender processes and identified as part of the Package Procurement Strategy.

As an example, here are some of the questions raised to potential supply chain partners:

Balfour Beatty VINCI has a target to reduce carbon emissions by 50% compared to baseline on this contract and maintain PAS2080 certification. Please outline how you would support these commitments by providing specific details of how you would reduce carbon emissions from offering low-carbon materials, transportation and/or plant. Please provide supporting examples and information. We expect suppliers to evidence and validate any claims. On request, sub-contractors will also be required to provide us with all relevant documents relating to the embodied carbon of the products and services provided, either in the form of a Life Cycle Analysis, Environmental Product Declaration (EPD) or carbon analysis. Suppliers should also provide any other relevant data so the impact of the product or service can be fully assessed. This will be determined in relation to the scale of the carbon impact of the product or service. We would also expect to be kept updated on any carbon savings or losses associated with any changes in the manufacturing process.

Please indicate how you monitor monthly production for environmental reporting purpose: energy/fuel use, water use, waste produced, and materials used (steel, concrete, lime, aggregate, timber, other). Detail how this data is assured for integrity, particularly in the event that subcontractors are used to provide services. Please provide details of who your reporting contact will be.

Please list key materials and resources planned to be used on site, evidence that they will be sustainably sourced, their intended use and their end-of-life plans. This will be part of the monthly reporting requirement. For more information on which materials require sustainable sourcing, please see the Supplier HSEQS Conditions. Certain materials may be required to be procured under BBV framework agreements. This inventory will need to be updated with as-build data at the end of the work package.

A key component of sustainable value is the proactive management of environmental, ethical, social and health and safety impacts throughout our supply chain. The Construction Family is the group of organisations that have been identified as critical project wide partners, that are essential to the successful completion of the Area North project. The Construction Family x Environment events are hosted quarterly by BBV to strengthen the relationship between BBV and these key suppliers and drive the sustainability agenda of the Project. Past topics covered have been waste minimisation, concrete technical standards and the evolution of specifications, carbon as-built evidencing and how to attain Environment Product Declaration (EPD) certification. These workshops have seen increasing participation with over 21 key suppliers represented in the last occurrence.

Carbon action plans

Throughout the construction phase, BBV is promoting sustainable practices and strategies to optimise energy usage and reduce resource wastages. This includes conducting energy audits across the sublot sites to identify areas of high energy consumption, potential energy-saving opportunities, and areas for improvement in applications such as lighting, HVAC systems, construction equipment, temporary utilities, and office spaces.

By implementing identified energy-efficient measures, BBV enhances its overall sustainability profile and reduces environmental impact of its operations, lower energy consumption/costs, maximise renewable energy utilisation and achieve relevant certification standards.

To support the implementation of these sustainable practices, all sublots were asked to take ownership of their specific carbon reduction action plan and a network of Carbon Champions has been established. Monthly meetings are held with each Sublot’s Carbon Champions to accompany them and drive the action plans.

As sublots are all organised differently, Carbon Champions have varied profiles. The only requirement was that they were not environment professionals; environmental team members can take part actively in the groups but cannot be the sole member. Their role is described below:

- Highlight existing practices that the sublot are already undertaking.

- Put forward the business cases for carbon saving practices/products to the sublot Design, Production, Quality, H&S, Environmental, and Commercial disciplines for approval for use.

- Arrange and coordinate meetings monthly workshops with the above to identify ideas on Carbon saving innovations that can be implemented on the sublot – Carbon Team can attend to help facilitate.

- Liaise with the Environment team/Carbon team to produce toolbox talks or newsletter articles on the implemented measures.

- Liaise with Project Carbon Lead and attend forums with other Carbon Champions across the trace (Carbon Impact Team meeting every 2 months to share good practice, avoid reinventing the wheel, and to get any blockers actioned by the executive that attends).

As an example, the Sublot 4 carbon champion has undertaken actions in 2023 that are estimated to have saved 2,840 tCO2e.

Design management

To ensure that environmental performance is achieved reliably, Area North have utilised the principles of PAS 2080 in design management. Throughout, designers, carbon specialists and other stakeholders have worked collaboratively to design out or drive down the embodied and operational carbon in permanent asset design, evidenced by LCA calculations.

Outcomes

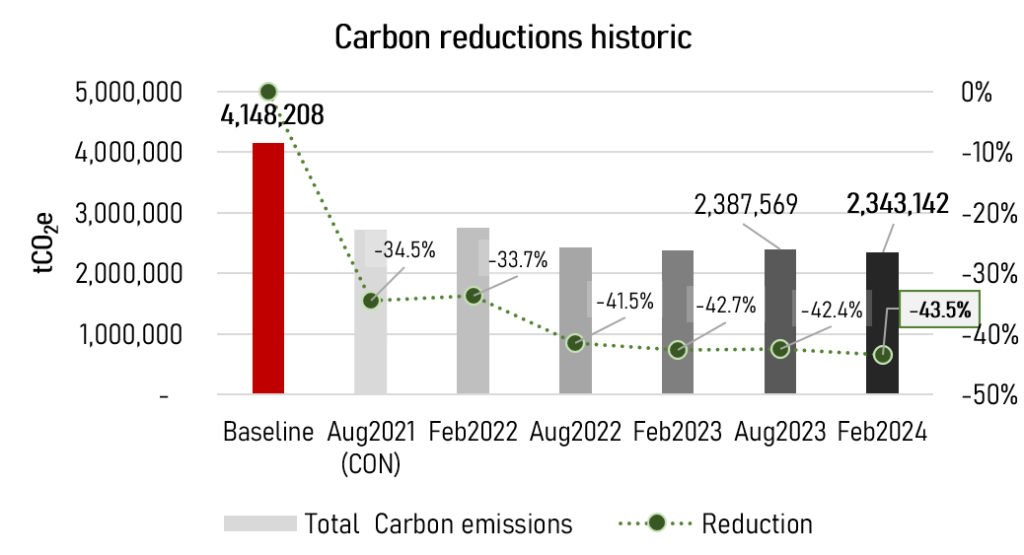

Carbon emissions have reduced by 43.4% from baseline to the latest LCA carried out in August 2024. Reductions have steadily decreased across the 3-year period, but those figures are expected to stabilise as data reliability is increased (Figure 4). This will continue to be tracked until construction is completed to monitor progress towards the 50% target. The last LCA carried out will be based on the As-Built data.

Design-led reduction opportunities:

The reductions seen so far have largely been driven through design optimisation in a small number of asset types, with retaining wall structures seeing the highest reduction at 87%. This asset type contributes a relatively minor amount to the overall lot wide footprint, but it becomes more significant when combined with some small reductions for asset types that contribute far more to the overall footprint. For example, embankments contribute 22% to the total carbon footprint and have seen their asset-type footprint reduced by 41%. Cuttings contribute 10% and have reduced by 38%.

The layout of the route and assets is such that there was opportunity for many asset design optimisations. This led to a large reduction in carbon emissions, for example:

Alignment optimisation:

- Streethay cutting and its associated assets were considered as a whole to optimise the alignment and redesigned, which led to significant savings. The initial retaining wall length was divided by four from 1.6km to 420m and changed to an open dry cut, therefore, material needs were decreased as well as road transport. This led to a carbon reduction of 480,000 tCO2e.

Retaining wall optimisation:

- Replacing a retaining wall by an open cut or changing its shape from D-wall to secant piles contributes to reduce the carbon footprint. The D-wall offers a relatively compact operation in comparison to the equipment required for secant piles leading to less energy use for equipment and less wastage. This solution was adopted in Rookery retaining structure. The open cut strategy has been applied in Stonehouse cutting and Stoneleigh Retaining Wall.

Viaduct optimisation:

- Implementing spherical bearings with a longer lifespan in viaducts. This solution was adopted in River Cole East and West viaducts, with bearing lifespan increased from 25 to 40 years, and even up to 60 years on the River Cole Viaduct. This led to a 50% reduction of the B4 (replacement) carbon emissions.

- Standardising the shape of piers. On assets such as Balsall Common viaduct and M42-M6 Motorway Link East and West viaducts, a standardised Y-shape of the piers has reduced the concrete quantities. Per pier, this is a reduction from 139,743 m3 in 2021 to 114,683 m3 of concrete in the current design. This 18% volume reduction directly translates to carbon savings.

- The M42 Marston Box structure has reduced its carbon footprint by 35% from baseline following the removal of the north and south retaining walls and a change to using the jack box construction method instead. This significantly reduced quantities of steel and concrete, avoiding 2,538 tCO2e.

Embankment optimisation:

- By optimising the embankment slopes from 1V:2.5H to 1V:2H, the amount of soil and associated earthworks use were reduced. Gilson Embankment, Watton House Embankment and Faraday Avenue Embankment are few examples of this optimisation.

During these design optimisations, some assets have undergone a sift (design optioneering) process. This enabled informed decision making with all environmental aspects considered, including carbon. This is the case of the Bromford Tunnel extension, with significant embankment, cutting and viaduct assets removed. This resulted in approximately 20,000 tCO2e avoided, but also major reductions in water, biodiversity, noise, and road impacts.

These reductions are just a sample of the asset changes on BBV’s route. While these savings are dependent on the setting of the project and in some cases the design changes cannot be made, they make a great case for the PAS2080 methodology. The highest savings are identifiable either at the “build nothing” or the “build less” phases.

Carbon increase risks during the design phase

The non-exhaustive list above highlights carbon reductions led by design, however, it is helpful to underline that there are also risks of carbon increase during that phase. For example, soil improvement might be designed prior to all the latest ground investigation data being available. This means that a conservative approach would be taken, and the foundations could be oversized. There is also a risk that this would lead to a change in the piling techniques used in the construction phase.

Learning and recommendations

BBV’s carbon reduction journey has given a better understanding of what went well but also what didn’t go so well.

To help anyone wanting to adapt this approach for their own projects, a few key recommendations have been highlighted in this section.

What worked well

- Identifying Carbon Champions within every sublot helped drive carbon, energy efficiency, cost savings as well as mitigate blockers by liaising within the site teams. Champions are accountable for getting the actions done on the different sites, which pushes for a more widespread implementation than if that responsibility fell on a central team with no budget. They are not from the environmental teams of the sublots, though they can get support from them, and ideally have some amount of experience getting initiative financed and approved. This approach is recommended to any large scale project with multiple sites

What could be improved

- Assigning opportunities to individuals: A Resources and Carbon Opportunities Register was managed to ensure that sustainability opportunities were captured. However, that register was too rigid and did not allow for dynamic tracking of the implementation – or not – of the opportunities. All opportunities should be assigned to individuals, the review frequency should be quite high, and the document should be a collaborative register.

- Developing a process to embed opportunities that demonstrate savings: linked to these opportunities for decarbonisation, a process should be designed to embed technological innovation and promote continuous improvement with demonstrated savings. For example, mandating generators with battery storage units across all sites after the initial trial and business case have been assessed. It is likely that linking this process to the role of risk managers, who look at both threats and opportunities, would result in a better rate of implementation of the opportunities.

- Data management – training key teams on carbon calculation – a lot of the data used to calculate carbon comes from a few specialist teams, and they need proper training into what is needed from them and how to provide it to the carbon teams. The carbon data structure should be built correctly from the start (carbon tags for example), and as many checks as possible (data integrity and quality) should be automated.

Data management – linking carbon and financial data – for financial data, a system to link budget projections and carbon should be automated. Financial teams should be trained in the importance of quantities being correctly updated and associated to assets at all stages of the project. On top of that, having carbon and financial data held in the same place should help make it a key decision factor at all stages of the project.

Data management – including EPDs in the Material Acceptance Records – for material specific data, a lot of certifications and specifications are collected by the quality teams. Integrating the collection of EPDs in the Material Acceptance Records (MAR) should improve the number of EPDs collected and therefore used in the LCA.

- Data management – setting up asset level carbon data – when starting the carbon footprinting process, it is important to set-up data in a way that is comparable at all stages of the project. Going down to asset level and not programme asset from baseline should enable better tracking of carbon evolution. Furthermore, establishing an intensity unit for all the asset types, and measuring progress like this as well as with an absolute value would further help to identify decarbonisation opportunities. For example, this cannot be done when a larger embankment includes the overbridges, culverts and the embankment, while some culverts are measured individually.

Identified gaps following on from the work that was undertaken

- Incorporate carbon requirements into job descriptions – it is strongly suggested that anyone wanting to implement a strong carbon culture to transcribe those carbon requirements into job descriptions. If individuals have a carbon role in their job description upon starting that job, they will not see any carbon work as additional to their normal job. It will become part of the expected tasks.

- Incorporate carbon requirements into annual objectives – having annual objectives targeted at carbon would help push this agenda ahead. To devise appropriate targets for the different levels, teams, and actions to decarbonise is key as it creates better ownership of actions. Engagement will be better with accountability and progress tracking, ideally on a dashboard frequently updated and accessible to all. The organisation structure has changed several times on this project, making it difficult to maintain a coherent split and representation of data.

Conclusion

In conclusion, a carbon reduction pathway must be built as a holistic approach. It must be infused at all levels of the organisation and ingrained into the culture. The strategy to reduce carbon on the Area North project needed to accommodate the dynamic nature of the works as well as to evolve in time with the project.

This learning legacy is but a brief insight into the items that need to be addressed in order to drive carbon out:

- Excellent data management to get the most reliable picture of the project’s footprint, as well as to be able to set and track meaningful targets at all levels of the organisation.

- Carbon to be questioned at all stages of design to ensure it is driven to a minimum.Assigned responsibilities to individuals at all levels of the organisation, and its subcontractors, to reduce carbon and bring forward new reduction opportunities.

The climate crisis will impact everyone of us; carbon reduction is everyone’s role.

Acknowledgements

Elliot Shiers, Lydia Wong, Papa-Samba Drame, Killian Bohan, Nisrine Ahagan

References

Carbon Net Zero Guidance Note. (2022, September). Retrieved from GOV.UK.

HS2 Net Zero Carbon Plan. (2022, January 11). Retrieved from HS2.

PAS 2080, T. A. (2023, April 5). Guidance Document for PAS 2080: carbon management in buildings and infrastructure. Retrieved from ICE.

The Climate Change Act 2008 (2050 Target Amendment) Order 2019. (2019, June 26). Retrieved from legislation.gov.uk.

Promoting Net Zero Carbon and Sustainability in Construction Guidance Note. (2022, September). Retrieved from GOV.UK.

High Speed Two (HS2) Ltd. HS2 Phase One Environmental Statement. Department for Transport 2013.

PAS 2080, T. A. (2023, April 5). Guidance Document for PAS 2080: carbon management in buildings and infrastructure. Retrieved from ICE.

PAS 2080: British Standards Institution. Carbon management in infrastructure. PAS 2080:2023. London: BSI; 2023.

HS2 Technical Standard – Carbon Footprinting and Life Cycle Assessment.

BS EN ISO 14040: British Standards Institution. Environmental management – Life cycle assessment – Principles and framework. BS EN ISO 14040:2006+A1:2020. London: BSI; 2020.

BS EN ISO 14044: British Standards Institution. Environmental management – Life cycle assessment – Requirements and guidelines. BS EN ISO 14044:2006+A2:2020. London: BSI; 2020.

BS EN 15978: British Standards Institution. Sustainability of construction works – Assessment of environmental performance of buildings – Calculation method. BS EN 15978:2011. London: BSI; 2011.

Supporting materials

Carbon Management Plan

Detailed Design – Basis of design – Carbon & LCA

Sustainable Sourcing Plan

Supplier Health, Safety, Environment, Sustainability and Quality Conditions