Clean Air Gas Engine (CAGE): reducing emissions by replacing diesel power in construction

In line with the UK government net-zero carbon by 2050 commitments, this project was aimed at cutting carbon and improving local air quality, High Speed Two (HS2) has trialled a new ultra-clean generator technology developed by a collaboration of three UK technology companies.

A collaboration between a power generation product developer, a generator manufacturer and a site welfare specialist led to the development of the low emission, off-grid, electricity generation solution into a welfare cabin specifically designed for the needs of construction contractors. It is a hybrid energy system which utilises battery energy storage with solar panels to boost charging.

The Clean Air Gas Engine project was funded by Innovate UK, which was supported by the UK government as part of the Clean Air Programme. The trial commenced on HS2’s construction site near Euston station in December 2020, run by HS2’s enabling works contractor Costain Skanska joint venture.

The system uses clean gas and biogas fuels as a replacement for diesel, with the aim of delivering breakthrough reductions of exhaust gas emissions and over time moving to full carbon neutral capability.

During the trial, exhaust emissions were monitored by specialists from Imperial College London, with results showing significant improvements in air quality and welfare conditions for construction site workers, leading to positive public health and wider environmental benefits.

Introduction

Air quality is important for both human health and wellbeing, as well as the environment. The World Health Organisation (WHO) estimates air pollution as the biggest environmental risk to health, carrying responsibility for about one in every nine deaths annually[1]. Air pollution continues to rise at an alarming rate, and affects economies and people’s quality of life, thus it is emphasised as a public health emergency.

The National Atmospheric Emissions Inventory (NAEI) highlights the construction industry as being a key source of air pollutants across the United Kingdom, with exhaust emissions from Non-Road Mobile Machinery (NRMM) diesel equipment being a significant contributor[2]. In a study undertaken by Imperial College London in 2020, it was noted that generators were the highest source of oxides of nitrogen (NOx) emissions from NRMM used across the High Speed Two (HS2). Phase One early works programme[3].

Innovate UK, supported by the UK government as part of the Clean Air Programme funded the development of the Clean Air Gas Engine (CAGE), as a direct alternative to diesel generators within construction. OakTec Power, an innovation and product development business specialising in world leading solutions for fuel efficiency and emissions reduction, collaborated with generator manufacturer Sutton Power Engineering and site welfare specialist Advanté to develop the first low emission, off-grid, electricity generation solution into a welfare cabin specifically designed for the needs of construction contractors.

Aimed at cutting carbon, supporting the UK government net-zero by 2050 objectives and improving local air quality, HS2 trialled this new ultra-clean generator technology at an Enabling Works Contractor’s site – Costain Skanska JV’s (CSJV) site in Euston. On-site emission testing was carried out by Imperial College London to quantify the emission saving potential of this solution in comparison to conventional diesel alternatives.

The Clean Air Gas Engine

OakTec and partners set out to develop and trial a viable alternative solution to red diesel fuel used extensively in the construction sector; and in particular to deliver air quality and carbon benefits through reducing of harmful emissions. The project involved the development of new gas engine technologies, incorporated into gas-solar battery hybrid power systems for off grid buildings and welfare units, which are widely used across the construction sector.

Development

The CAGE solutions apply state of the art digital control and previously developed combustion strategies for gas fuels to simple industrial engine platforms. The objective is to run a precise combustion regime using lean air-fuel ratios where the NOx emissions are very low. Precise control of load demand, fuelling and ignition plus fast response to external conditions allows the combustion to be held in this narrow band over the full operating cycle of the engine.

This combustion strategy eliminates carbon monoxide (CO) emissions and significantly reduced NOx at source whilst keeping hydrocarbons and particulates to a minimum.

The engine development work took on the challenge of changing a basic low-cost industrial engine to a highly sophisticated and precisely controlled gas engine with digital control of fuelling, ignition and load and intelligent response to ambient conditions. This development focussed on OakTec’s ‘cool combustion’ and integration of the resulting product with solar- battery hybrid.

In application, the engines were integrated into Advanté’s Patented telemetry controlled solar battery hybrid power system in the off-grid site welfare units built within the project. These maximise the use of renewable energy whilst minimising engine operation hours and, through use of battery power storage, allowing the engine to only operate at its cleanest and most efficient. This hybrid system reduces engine use from 24/7, in the case of a conventional diesel system, to 1-3 hours per day, with the highest use being in mid-winter. The engine has stop-start and only engages when the battery state of charge is low.

This engine labelled CAGE 6PG was integrated into an Advanté welfare unit, as shown in Figure 1, and with full hybrid functionality, began trials with HS2 and CSJV at Euston in November 2020.

Ultra-clean engines and reduced use allow the greatest emission reduction benefits, which ensured the CAGE project exceeded its targets and demonstrated great reductions in

health-harming emissions that damage air quality without any inconvenience to the plant and site operators, further reducing impacts on surrounding communities.

Site trial

Aimed at cutting carbon, supporting the UK government net-zero commitments and improving local air quality, HS2 Ltd and CSJV trialled the first new ultra-clean generator technology integrated into an Advanté welfare unit at the Euston Station site in London over a 12-month period, as shown in Figure 2. The on-site welfare unit consisted of an office area, canteen, charging and drying room and loos. The unit was extensively used by the site teams throughout the trial.

The welfare cabin operates silently on stored energy and uses Advanté’s EcoLogic curfew technology to limit noise during unwanted hours, further reducing any negative impacts on the user, operatives on site and surrounding local communities.

The on-site trial was a huge success in replacing diesel power with this hybrid solar LPG technology. The trial showcased a total kW/hr power consumption of 359 kW/hr over the period. Of which the power consumption of 74 kW/hr was from the CAGE, with the remainder from solar energy. This represents a 79% via solar to 21% via CAGE, resulting in a significant carbon savings.

Emission results

The trial was remotely monitored for load profiles and gas usage. Emissions were independently measured by Imperial College London, both on site and in the Helical laboratory, to quantify the emission saving potential of this solution in comparison to diesel alternatives.

The EU has adopted a series of directives over the past two decades to address emissions from non-road engines. These directives set the emission limits engines must meet within various engine bands for NRMM. The current most stringent emission standard for NRMM is EU Emission Stage V, with engines having to meet very stringent emission limits to be certified.

The CAGEs trialled on HS2 only emitted 20% of the level allowed by the latest EU Emission Stage V standards without requiring costly after exhaust treatment systems to be fitted.

When this clean engine was further integrated into a solar hybrid system with automatic stop-start, there was an overall emission reduction, including CO2, as low as 5% of the level of a conventional diesel engine running in the same application.

Tests were performed on both the CAGE, and equivalent diesel engines, under laboratory conditions with the engine loaded using a dynamometer. The test cell allowed for the engine calibration to be adjusted whilst emissions were measured using Horiba exhaust gas analysers alongside Imperial’s 3DATX portable emission measurement system (iPEMS).

Field trials were conducted on the unit at the HS2 site, using the iPEMS system, to measure the total emissions whilst the engine was run at set power loads in a real-world working environment. Both tests demonstrated the significant emission reduction benefits of using the clean air gas engines over conventional diesel engines.

For the Stage V emissions test, an aggregate of the components of CO, Hydrocarbons (HC) and Oxides of Nitrogen (NOx) are taken from the exhaust emissions during a regulated engine test cycle. CAGE 6PG was tested on this cycle and benchmarked against a directly comparable liquid fuelled engine that meets the 2020 Stage V standard. Tailpipe summed total emissions reductions of CAGE vs the Stage V engine were as follows; CO 99.5%, HC 86%, NOx 20%. The tests took place at Helical’s new emissions lab using automotive standard state of the art Horiba measuring equipment.

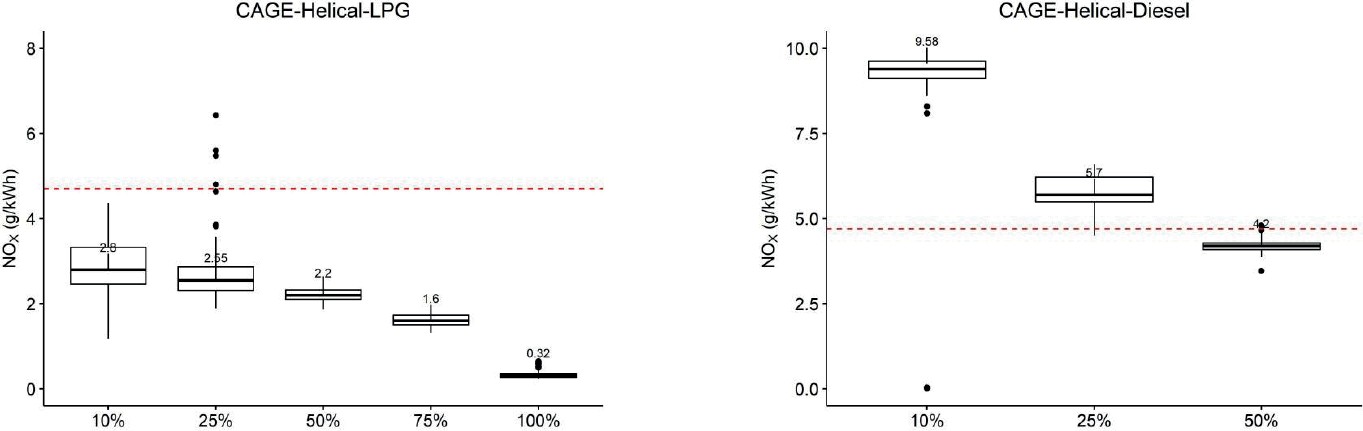

The results highlighted the CAGE was below the EU emission Stage V standards (4.7 g/kWh for NOx+HC – showen by the dotted red line in the graph below); while the diesel engine was above the same emission standards for 0.4kW and 1kW load points.

The results showed significant improvements in air quality and welfare conditions for construction site workers, leading to positive public health and wider environmental benefits.

Conclusion

This non-fossil fuel welfare solution, i.e. using renewable solar energy and bio-LPG to meet for energy demands, enables continuous running with no downtime needed for refuelling, significantly reduces the total carbon footprint compared to diesel systems and is currently cost competitive with red diesel. This creates the lowest CO2 impact combined with a game- changing reduction in the total exhaust gas emissions achievable on this type of installation. The CAGE project addresses the challenge of reduction in health-harming tailpipe emissions from NRMM diesel engines in the construction sector.

This successful trial is a significant step forward in decarbonising the construction industry, supporting the UK government net-zero objectives, while reducing local air pollution.

Diesel engines are now regarded as unsustainable as the world moves towards a cleaner environment and greatly reduced emissions. Now proven, the CAGE technology, once scaled up, offers the construction industry a reliable, cleaner alternative solution to diesel without interference to the construction site, operatives or surrounding communities.

Next steps

This trial was the first of a series of gas engine innovations and emission reduction technologies OakTec are developing for the construction sector. The next step is the launch of a higher output multi-cylinder engine also developed in the CAGE project. This engine is a development of the latest 3-cylinder Jaguar Land Rover automotive unit is now testing in a 27kW generator that will be trialled at Euston in early 2022 to replace an existing diesel machine. It will use directly injected bioLPG and automotive standard aftertreatment to set new standards in NRMM tailpipe emissions.

This development aims to support UK engine manufacturers post the 2030 diesel and petrol combustion engine private car ban. Investigations are underway to consider the use of future electric car batteries for use in this hybrid system. This process will support the circular economy and reuse of car engines and battery systems into the future.

Post the HS2 trials, and lessons learnt, these products will move forward to the production phase with further roll-out planned for the project and the wider construction industry. A new OakTec company, CAGE Technologies Ltd, has been formed to commercialise outputs from the CAGE project and those of parallel biogas and hydrogen related development programmes.

To support the objectives of clean air and net zero, the NRMM market needs a facility to enable certification of new clean technology in a speedy and cost-effective manner. A dedicated UK facility is the only route to enable this. Supported by Innovate UK funding the laboratory based near Preston at the Helical Technology research facility was established during the CAGE project to serve this function.

OakTec has been conducting intensive research into efficient combustion of gas and biogas fuels since 2013. For the first time, a biofuel capable hybrid system delivers greatly reduced levels of harmful emissions, in a cost-effective generation solution. The breakthrough gas engine generator manufactured by Sutton Power Engineering is integrated into a welfare cabin from the market leader in green technology in this sector, Advanté.

CAGE technologies have widespread applications and can be used in many applications currently served by diesel and petrol engines. Sectors including agriculture, marine and non- automotive transport. Building power systems using CAGE CHP (heat recovery) is another major opportunity for the technology. Futureproofing for net zero will be addressed by the adoption of green hydrogen, e-fuels and biofuels.

Future collaborations are in discussion to trial these early-stage net zero technologies on HS2 and, by working with the project contractors, develop fit for purpose solutions that can rapidly transition into commercial products.

A video, published by Innovate UK, detailing the CAGE project and benefits is available at https://youtu.be/zl8V0F2xzaI.

Acknowledgments

Advanté Ltd. Calor Gas

Helical Technologies Ltd Imperial College London Innovate UK

Jaguar Land Rover Sutton Power Ltd.

References

[1] World Health Organisation (2016). Ambient air pollution: A global assessment of exposure and burden of disease. Geneva: WHO document production.

[2] National Atmospheric Emissions Inventory (2019). Department for Business, Energy & Industrial Strategy.

[3] Desouza, C., Marsh, D and Green, D. (2020). Calculating the NOx emissions inventory for NRMM used on HS2 sites. Centre for Low Emission Construction, Environmental Research Group, Imperial College London – Unpublished.

Peer review

- Mike WhiteHS2 Ltd

- Mike de Silva HS2 Ltd