Construction stage geo-data collection, reporting and visualisation – digital workflow

This paper presents an innovative digital workflow designed to address the challenges associated with collecting, reporting, and visualising construction stage geological and geotechnical ground data (geo-data). It emphasises the importance of this data in informed decision-making, to achieve efficiencies, optimisation, and, most importantly, risk assessment and mitigation. The limitations of traditional geological mapping workflows and specific challenges faced in the C23 project are discussed. Subsequently, the digital workflow is introduced, outlining its application to the validation of design, geohazard identification and mass haul efficiencies. The benefits of implementing the digital workflow are discussed, followed by an exploration of prospects for digital geo-data, including the potential contributions of machine learning, augmented reality, and virtual reality to future infrastructure projects.

The applications of the digital geo-data workflow extend beyond C23, remaining relevant to other phases of the HS2 project and Main Works Civils Contractors (MWCCs) involved in collecting construction stage geo-data.

Background and industry context

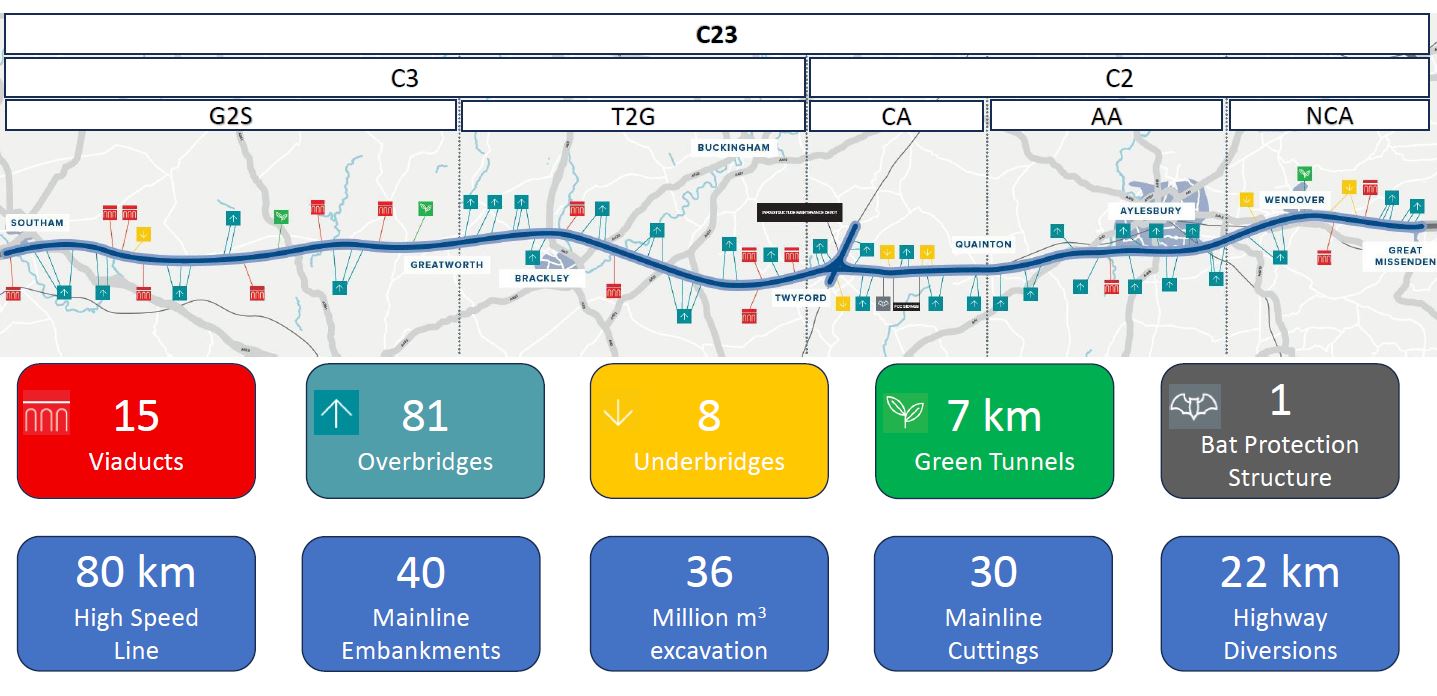

The Eiffage Kier Ferrovial Bam (EKFB) joint venture has been awarded the Central 2 and 3 contracts (C23) for the HS2 Phase One route. The C23 section, a critical part of the project, involves the construction of various assets, covering 80 km. These assets include cuttings, embankments, viaducts, bridges, green tunnels, and an intersection with East West Rail. For the successful execution of these assets, over 36 million cubic meters of earth excavation and transportation are required (Figure 1). To achieve this, a multidisciplinary Integrated Project Team (IPT) is collaborating, bringing together diverse expertise to ensure effective data-driven design and construction decisions are made. A crucial component of these decisions is the construction stage geo-data, which plays a vital role in shaping positive project outcomes.

Enhancing understanding with construction stage geological and geotechnical ground data

The HS2 project involves continuous observation of geology and ground conditions along the route. This paper specifically focuses on the construction stage, which offers a valuable opportunity to collect precise and comprehensive geo-data that might not be adequately captured during pre-construction mapping and ground investigations (GI). Pre-construction ground models offer initial observational understanding based on limited borehole data, yet they often lack the necessary detail, especially for complex geological features like faults and discontinuities. Therefore, the construction stage plays a crucial role in acquiring high-resolution geo-data, providing a thorough and comprehensive understanding of ground conditions. These direct observations are vital for identifying potential issues and optimisation opportunities, enabling timely modifications to ensure project success, and, most importantly, safety.

Construction stage geological mapping inspections offer continuous observations and assessment as the project progresses, involving field assessments of in-situ exposures and ex-situ materials (e.g., pile arisings). This geo-data collection includes both geological and geotechnical information. Geological data encompasses lithology, stratigraphy, and structural characteristics, while geotechnical data relates to physical and mechanical properties of the ground, such as density, strength, and stiffness.

The pre-construction ground models for the C23 section highlight considerable geological variations along the route, including complex features and heterogeneity. These variations can have a significant impact on the design and safe construction of assets. While the design was based on the best available information at the time, it is vital to adapt to the actual conditions encountered during construction, rather than solely relying on initial design assumptions. As a result, the higher resolution geo-data collected during the construction stage becomes critical in ensuring the suitability of asset designs, addressing potential geohazards, and selecting the safest construction methods.

Limitations of the traditional geological mapping workflow and C23 project challenges

The traditional workflow for geological mapping faces several limitations when it comes to collecting, reporting, and visualising geo-data during the construction phase. One major constraint is the fragmented approach, where data is acquired through disparate paper-based methods. This leads to inconsistencies and inaccuracies in the collected data, making the analysis and integration of the dataset challenging. As a result, the decision-making process is compromised, as the incomplete and inconsistent dataset may not provide a comprehensive understanding of the geological conditions.

Secondly, traditional workflows heavily depend on manual procedures, which suffer from limitations in spatial resolution, are time-consuming, and susceptible to errors. Field observations are often documented on paper, necessitating subsequent data transfer onto 2D maps and written reports. Such manual data handling introduces the potential for errors and inconsistencies. Moreover, the time and effort invested in manual processes leads to prolonged periods on-site, hindering the efficiency of data collection and management, and restricting the quantity of data that can be gathered and analysed. Consequently, on-site safety risks increase, and the decision-making process could be based on incomplete information.

Finally, traditional geological mapping workflows often rely on static visualisations, such as 2D maps and written reports to communicate geo-data. These static formats limit the accessibility and interpretation of the data.

The C23 project presents challenges due to its structure and diverse stakeholders, requiring simultaneous access to up-to-date geo-data for seamless collaboration. Ensuring data accessibility in such a large-scale project with dispersed teams is crucial to prevent decision-making delays and uninformed choices. Effective communication and collaboration among stakeholders are vital to integrate data into decision-making processes, reducing misinterpretations and delays for more efficient execution.

Approach

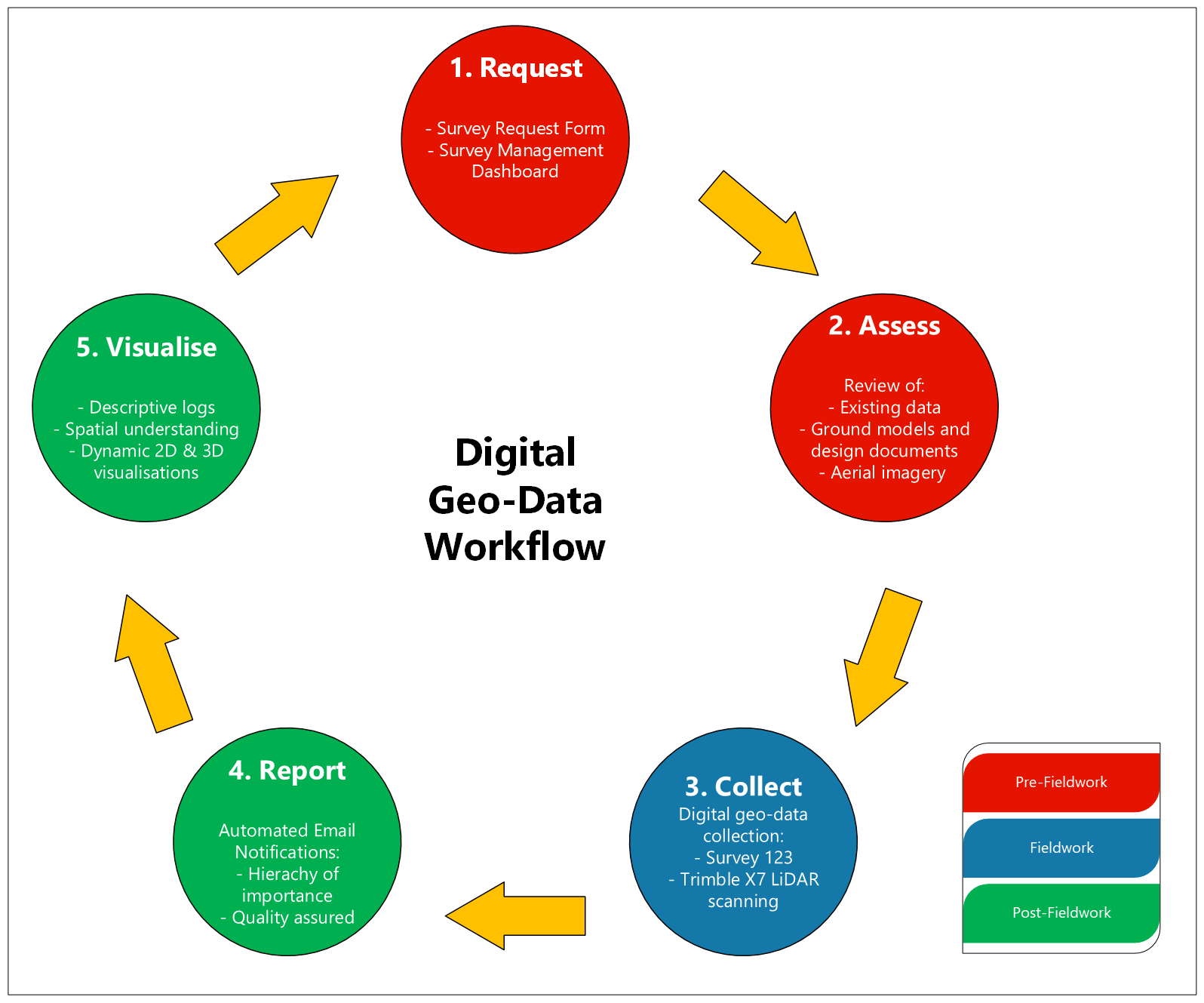

A multidisciplinary team from EKFB, consisting of geological, geotechnical, and GIS professionals, worked together to create an efficient digital workflow. This integration of advanced technologies aimed to overcome the constraints of conventional workflows and address challenges unique to the C23 project. The workflow was designed to align with the existing Trimble GNSS hardware and Esri GIS capabilities within the C23 project. Over a span of 12 months, the digital workflow underwent continuous enhancement and expansion, resulting in its current composition of five distinct stages (Figure 2):

- Request

- Assess

- Collect

- Report

- Visualise.

Geo-data survey request and desk assessment

The workflow commences with a pre-fieldwork phase where the survey objectives are identified by the requester. In the request stage, a digital geo-data survey request form is completed to collect crucial details such as survey location, scope, and timing, enabling prioritisation and scheduling of surveys. The mapping geologist manages this information and tracks it through a survey management dashboard. Moving forward in the pre-fieldwork phase, the geologist conducts a desk study and preliminary site assessment. This involves a thorough review of existing geological maps and documents, along with a remote site visit utilising up-to-date aerial imagery. These activities provide a fundamental understanding of the local geology, facilitating awareness of geological hazards and site-specific issues that could influence the project. These two stages ensure the mapping geologist is fully prepared to conduct an efficient inspection, limiting their time on-site and exposure to potential health and safety risks.

Digital geo-data collection and storage

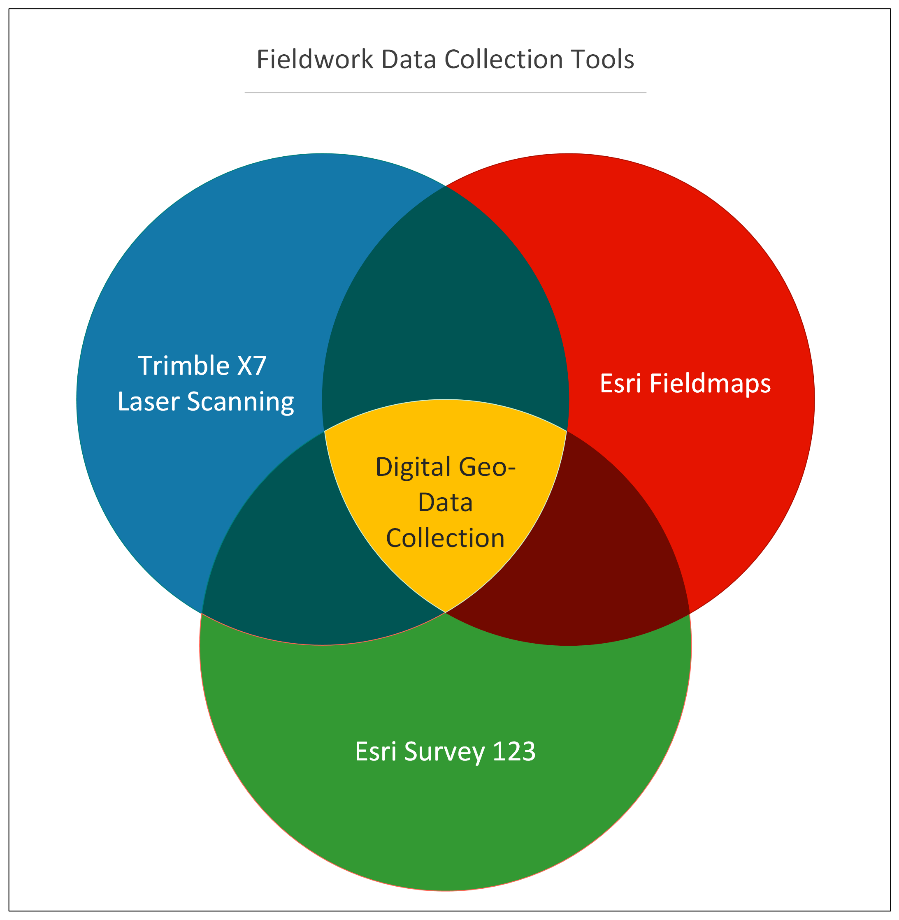

The advancement of digital technologies has developed the process of collecting geo-data during the construction stage of infrastructure projects. Cutting-edge surveying tools, including Global Navigation Satellite Systems (GNSS), Geographic Information Systems (GIS), and Light Detection and Ranging (LiDAR) scanning, have been seamlessly incorporated to facilitate the collection of construction stage geo-data (Figure 3).

To leverage the power of GIS and GNSS technology, two apps are employed in the field, enabling users to manage, collect, analyse, and report spatial, geo-data in real-time. The offline capabilities of these apps allow uninterrupted usage even in areas with limited or no internet connectivity. The first app used is Fieldmaps. The GIS app serves as a valuable tool for spatial awareness, integrating with high-precision GNSS receivers. This integration allows field workers to use a mobile phone or tablet to view their location on a customised map, providing context to their data collection efforts. By understanding the spatial context, field workers can identify relevant features and navigate efficiently.

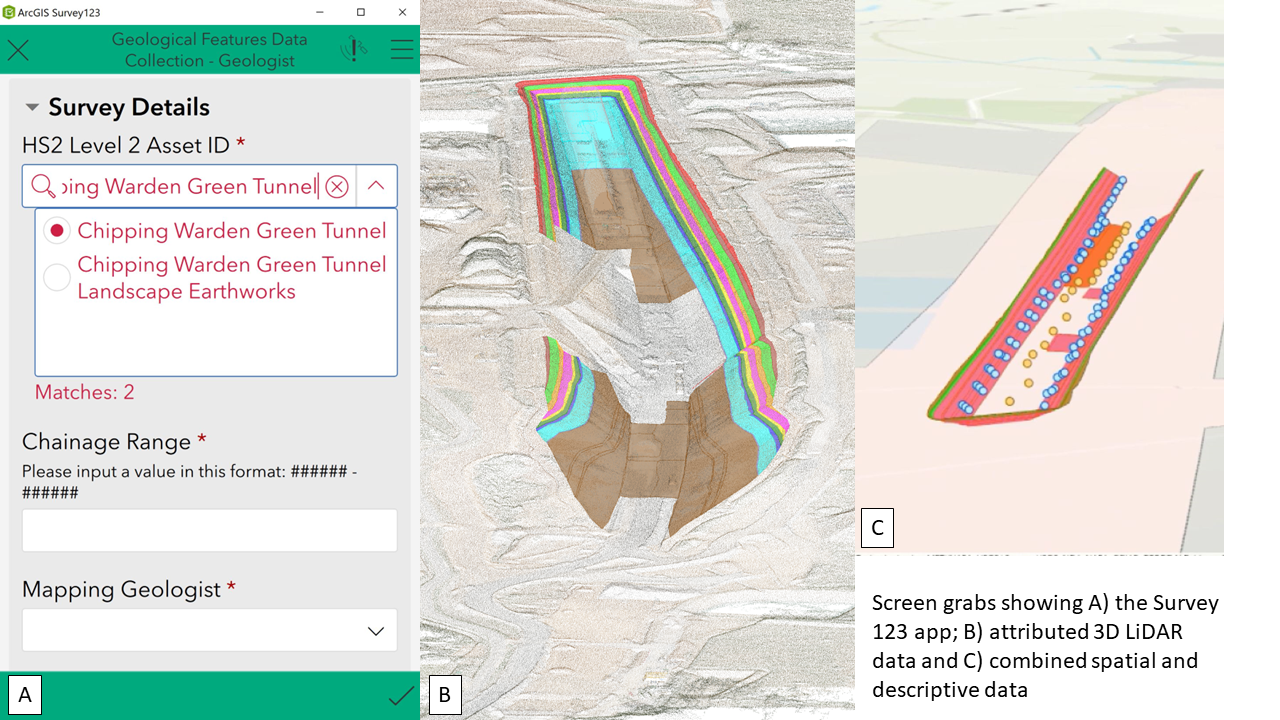

The second fieldwork app, Survey123 (S123), is used in conjunction with GNSS receivers to collect geo-data with high spatial accuracy using a mobile phone or tablet. A tailored attribute schema aligned with the BS5930:2015+A1:2020 framework[1] is implemented, ensuring adherence to established standards. Furthermore, quality control measures, such as mandatory fields and drop-down menus, are incorporated to uphold data integrity (Figure 4A). Considerable attention was given to designing the schema to facilitate the comprehensive collection of data pertaining to the diverse geological features potentially encountered in C23, including dissolution features and faults. S123 also facilitates the inclusion of supplementary visual data, such as photographs and sketches, which provide additional context to the collected data. Upon completion of data collection, the survey is submitted, and the app securely transmits the data to the cloud-based database associated with the survey.

In addition to the GIS apps, the Trimble X7 3D LiDAR scanner is employed to acquire vast amounts of spatial data from the ground surface, generating comprehensive 3D digital point clouds that form the foundation for 3D geological mapping visualisations (Figure 4B). This advanced scanner rapidly captures data, even from previously inaccessible or hazardous locations, reducing the need for personnel to work in such areas. By doing so, it not only ensures the quality of the acquired data but also enhances the safety of the mapping geologist on site.

Notification of collected geo-data

Submitted geo-data is transmitted to the cloud-based database in real-time enabling the stakeholders to access the latest data for sharing, analysis, and visualisation purposes. The utilisation of the Feature Manipulation Engine (FME) enables the generation of notification emails, which are automatically triggered based on predefined conditions and what was recorded during the data collection process.

A hierarchical reporting approach is used to ensure the prompt dissemination of critical data, with particular emphasis on information that has implications for safety, optimised design, and construction methods. These notifications are designed to be informative, actionable, and tailored to the appropriate members of the IPT. They contain pertinent details accompanied by direct links, facilitating the visualisation of the relevant and updated data.

Visualisation and analysis of geo-data

The data can be accessed and analysed by all members of the IPT using various websites. This increased connectivity allows for more effective collaboration and coordination among the IPT to improve safety. These tools enable users to analyse and visualise large datasets, allowing for a detailed understanding of the ground conditions and an assessment of the impact of these ground conditions on project outcomes.

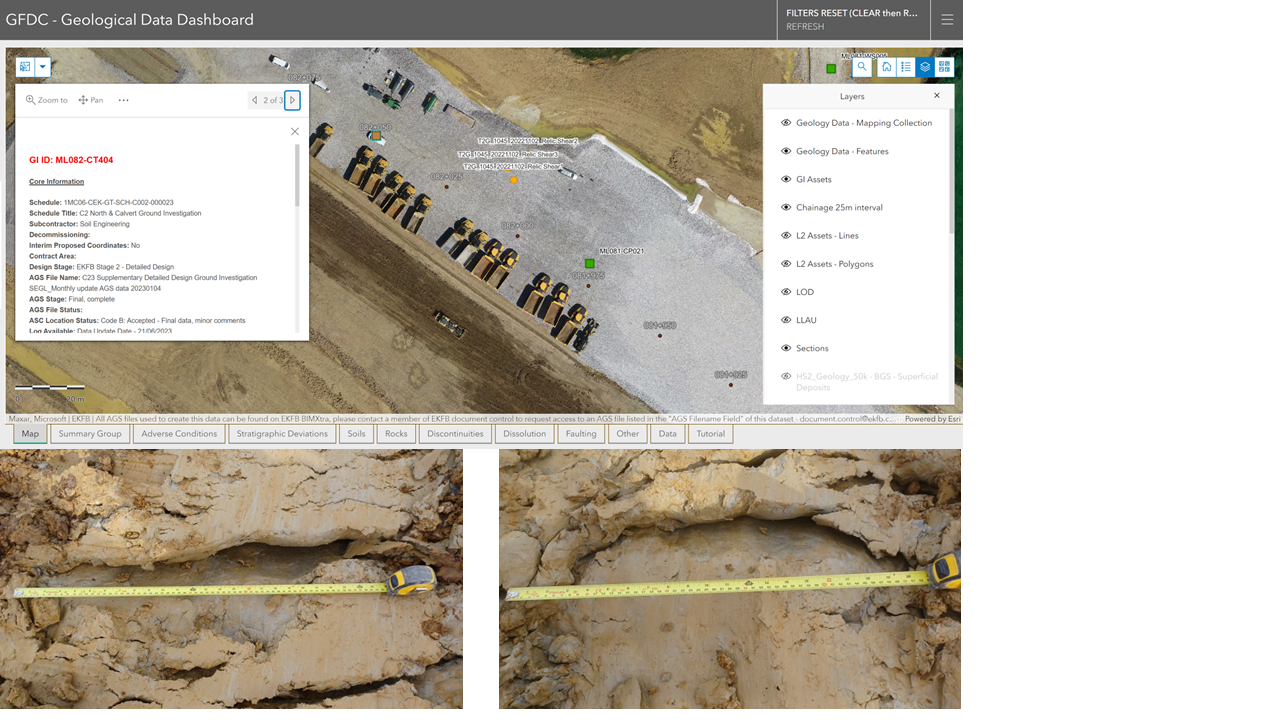

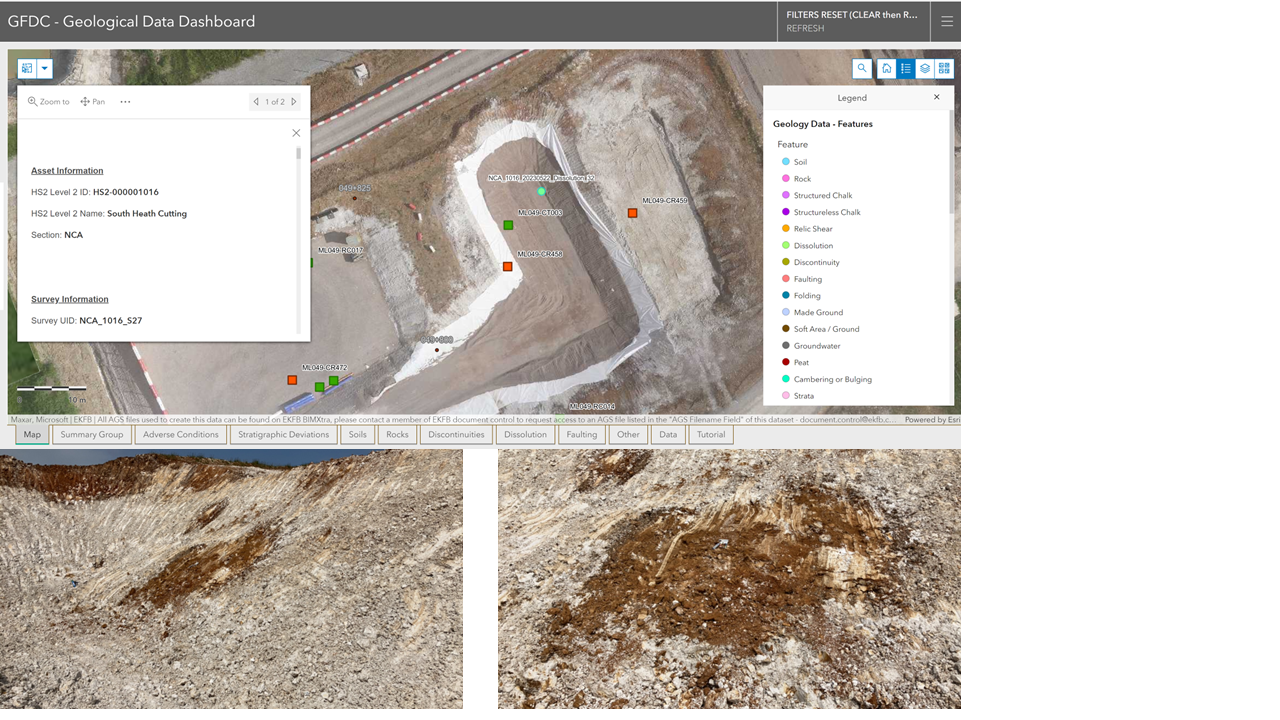

A GIS dashboard serves as a robust platform for facilitating data sharing among multidisciplinary stakeholders, ensuring seamless accessibility to meet their specific needs. The scalability of the tools makes them ideal for analysing the extensive datasets of geological field data from across the C23 project. The user-friendly platform enables real-time analysis of automatically synchronised geo-data and consolidates data from multiple sources in a coherent manner, thereby facilitating meaningful interpretation and analysis of the data. The dashboard offers a wide range of data visualisation options, including graphs, charts, photographs, tables, and maps, supplemented by sorting, filtering, and various analytical functionalities. Secondly, a 3D map is produced that integrates, manages, and analyses data. 3D LiDAR point cloud data of the ground surface are processed using Trimble Business Centre and attributed a geological context to generate precise geological surface models. Specific features are assigned the same unique identifier as the corresponding S123 log with the resultant combined output providing both descriptive and geometric data (Figure 4C). The 3D GIS models offer accurate spatial referencing and visualisation of geological ground data and can incorporate multiple data types, such as design data, and material testing data, to create a comprehensive view of the ground. Dynamic, interactive, and comprehensive visualisations are powerful tools for conveying complex information concisely. The digital workflow empowers stakeholders to view and explore these visualisations from different angles and perspectives, providing a comprehensive understanding of the data.

Outcomes

Application of construction stage geo-data in the C23 project

Comprehensive, readily accessible, user-friendly construction stage geo-data provides valuable insights into the ground conditions along the C23 route. This data plays a crucial role in understanding the interactions between the project and the surrounding environment. These data enable the identification of risks and optimisation opportunities, facilitating the implementation of cost-effective design and construction techniques while maintaining the highest standards of quality, safety, and functionality. The digital geo-data workflow is effectively applied for validating designs, refining models, identifying and mitigating geohazards, and optimising mass haul strategies.

Validation of design and refinement of models

The initial ground models developed for the C23 project are based on desk studies, existing geological knowledge, and pre-construction GI. Construction stage geo-data is essential for validating and refining the ground models used for asset design. Direct observations facilitate the identification of geological features, which may not have been sufficiently represented in the pre-construction models. By comparing the construction stage geo-data with the original data and initial ground models, any disparities or deficiencies can be identified and rectified, ensuring that the design adequately accounts for the specific ground conditions encountered on-site.

The construction stage geo-data is shared through the Geological Data Dashboard, providing spatial insights and facilitating comparison with existing data (Figure 5). This platform serves as a robust visualisation and analysis tool for construction stage geo-data and other datasets. It supports Contract Technical Committee (CTC) meetings, enabling stakeholders to address technical matters (e.g., presence of relic shears), share updates, and make informed decisions. This process enhances model validation and refinement using construction stage geo-data, thereby improving project accuracy, reliability, safety, efficiency, and cost-effectiveness. The dashboard promotes effective communication, collaboration, and coordination among team members.

Identification and mitigation of geohazards

Geohazards can pose substantial threats to the safety and integrity of assets. The failure to identify and mitigate these geohazards can lead to costly delays, rework, and potential accidents. For example, the southern section of C23 passes through a geological environment where geohazards related to dissolution features, like sinkholes and underground cavities, can pose significant risks. Construction activities expose large areas of the subsurface, thereby enabling the identification and assessment of geohazards that may not have been fully apparent during the pre-construction phase. This is significant in the context of dissolution features, as their distribution can exhibit irregular patterns and may not have been visible in proximal GI (Figure 6).

The presence or absence of geohazards is reported by the geologist to CTC stakeholders and the Ground Risk Register (GRR) updated accordingly. If geohazards are identified, further detailed investigations, optimised design modifications and mitigations are implemented to ensure the safety and integrity of the assets. Conversely, the identification of more favourable ground conditions, where geohazards had been predicted in the GRR but are absent, can potentially justify the relaxation of strict design requirements.

The identification and mitigation of geohazards using construction stage geo-data serve to benefit the C23 project by identifying risks and opportunities. As a result, the safety, efficiency, and cost-effectiveness of the project are significantly enhanced.

Optimised Mass Haul strategies

The HS2 project has established ambitious environmental goals, requiring the effective reuse of excavated materials via the implementation of efficient mass haul strategies. The classification of in-situ materials earmarked for excavation and re-use in the C23 section is guided by the Specification of Earthworks (SCEW) Series 0600[2]. Prior to the construction stage, comprehensive ground GI and material testing was conducted, and the data obtained was incorporated in the development of ground models. These models predict the spatial distribution and volumes of each material class within cuttings and deep excavations along the C23 route. Construction stage geo-data can provide a more accurate spatial awareness and a deeper comprehension of the geotechnical properties of the in-situ materials encountered and provide the basis for refining the 3D ground models, enabling more accurate predictions of spatial distribution and volumes of material. Identifying persistent limestone bands of consistent thickness (Figure 4B), for instance, can improve excavation strategies, minimising material waste. Mapping these limestone bands accurately and understanding their distribution empowers construction teams to plan excavations strategically. This knowledge facilitates targeted excavation of higher quality materials suitable for construction, while avoiding mixing with less desirable ones. By strategically stockpiling different materials in designated areas, effective management is ensured. Optimising mass haul is crucial for reducing unnecessary transportation, treatment, and disposal of site-won materials, and minimizing the need for importing additional material. This optimisation can result in substantial cost savings and environmental advantages.

Learnings and recommendations

Benefits of the digital workflow

The implementation of the digital workflow optimises the collection, reporting, and visualisation of construction stage geo-data, ensuring that it is accurate, accessible, and usable. The digital workflow overcomes the limitations of traditional geological mapping and the challenges of C23, bringing benefits to the construction stage and later in the geotechnical lifecycle.

During the construction stage of C23, the implementation of the digital workflow is expected to lead to substantial time savings. A comparison with a traditional mapping workflow indicates a reduction of over 16,000 hours, encompassing both on-site time and the production of written reports. The digital workflow empowers IPT stakeholders through the utilisation of advanced technologies, efficient data collection, standardised practices, automation, real-time data sharing, and improved accessibility and interactive data visualisation. This empowerment enables effective collaboration, informed decision-making, optimised project outcomes, and mitigation of geological risks, resulting in increased safety measures.

Future developments

Continuous advancements in technology, such as improved LiDAR capabilities and refined Machine Learning algorithms, hold immense potential for further enhancing geological mapping and visualisation. Prospects include the integration of AI-driven data analysis and predictive modelling techniques to optimise decision-making processes and risk assessment. By leveraging these advancements, the IPT can potentially unlock new insights, improve project outcomes, and effectively manage geological risks throughout the project lifecycle. Embracing these technologies ensures geo-data is used to its full potential, contributing to a safer and more successful C23 project.

LiDAR scanning combined with Machine Learning techniques offers a transformative approach to geological mapping. By integrating LiDAR data with AI algorithms, valuable insights can be extracted, which were previously difficult to obtain using traditional methods. Machine Learning algorithms could automate the identification of geological features, such as faults, fractures, and rock types, from LiDAR data. This could significantly speed up the mapping process and improve the accuracy of the results. Moreover, the combination of LiDAR scanning and Machine Learning enables the detection of patterns, anomalies, and predictions about future changes to the site. This information informs design and construction decisions, as well as helps mitigate risks associated with geological hazards.

Augmented Reality (AR) technologies enhance understanding by overlaying digital 3D geological models onto physical sites. Stakeholders can visualise geological features, potential hazards, and design elements in the context of the real-world environment. AR visualisation could improve stakeholder engagement, facilitate communication, and aid in on-site decision-making processes. Virtual Reality (VR) technologies provide a fully immersive experience, allowing stakeholders to explore and interact with digital geo-data in a virtual environment. VR visualisation offers detailed examination of geological formations, 3D models, and construction progress. It could enable stakeholders to navigate and analyse the project from different perspectives, enhancing their understanding and enabling comprehensive project analysis. Furthermore, VR visualisation could promote collaborative discussions and support effective communication, enabling stakeholders to make informed decisions based on a deeper understanding of geotechnical aspects.

Establishing a collaborative HS2-wide working group dedicated to sharing geo-data innovations and investigating the incorporation of artificial intelligence (AI) and emerging technologies could offer substantial benefits for expansive infrastructure projects such as HS2.

Conclusion

Accurate construction stage geo-data is crucial in the validation of design and construction of large-scale projects like HS2 Phase One. While pre-construction geo-data offer valuable insights, they can fail to predict the dynamic subsurface conditions during construction.

A streamlined digital workflow has been developed, integrating advanced technologies for accurate, accessible, and usable construction stage geological data. Implementing the digital workflow in C23 marks a significant advancement in construction stage geo-data management. It optimises data collection, reporting, and visualisation through efficient methods, standardised practices, automation, real-time sharing, and enhanced accessibility. By harnessing advanced technologies, stakeholders can collaborate, make data-driven decisions, optimise outcomes, and mitigate geological risks.

As the C23 project progresses, effectively using the digital workflow and exploring emerging technologies will enhance data collection, subsurface understanding, and project safety and efficiency.

Advancements in technology, such as improved LiDAR and refined Machine Learning algorithms, have the potential to enhance geological mapping and visualisation further. Integration with Augmented Reality (AR) and Virtual Reality (VR) can facilitate informed decision-making based on a deeper understanding of geotechnical aspects. Embracing these advancements and best practices paves the way for safer and more sustainable construction projects.

Acknowledgements

Special thanks go to the EKFB geology, GIS, and geotechnical teams for their contribution to the design and rollout of this workflow.

References

- British Standards Institute “Code of Practice for Ground Investigations has been updated” . Accessed 17 August 2023.

- Standards for Highways Feb 2016 “Manual Of Contract Documents For Highway Works Volume 1 Specification For Highway Works; Series 600 Earthworks, P1-2” . Accessed 17 August 2023.

Peer review

- Charlotte HillsHS2 Ltd