Control of hand and arm vibrations on HS2 and beyond

Hand Arm Vibration Syndrome (HAVS) is a health condition caused by the vibration from any hand-held, fed or guided power tools and machinery on site, e.g. drills, torque wrenches, plate compactors etc. HAVS causes damage to muscles, nerves, joints and blood vessels, leading to permanent long-term health. Over two million people in the utility and construction sectors in the UK are at risk of developing an HAVS-related condition[1].Each year over 80 instances of HAVS are reported to the Health & Safety Executive as a RIDDOR (Reportable Injuries, Diseases and Dangerous Occurrences Regulations) reportable disease. (Schedule 3 part 1 of RIDDOR Regulations 2013)[2]

The A41 on-site batching plant located near Aylesbury in Bucks, required thousands of bolts to be fixed in, causing potential vibration to operatives through a metal spanner and torque wrench. Tests showed that the vibration levels were double the upper value exposure level.

A simple and cost-effective solution in the form of a rubberised/insulated sleeve was added to the spanner handle costing approximately £1.50 per spanner. With the rubberised/insulated sleeve added to the spanner handle further test results showed that the effects of vibrations were only a 20th or 5% of those previously. The sub-contractor involved agreed to use the new method on future contracts worldwide, and this learning event has raised awareness of HAVS across the Aylesbury area with the introduction of HAVS medical assessments for operatives and Reactec’s HAV’s monitoring system to monitor HAVS on a daily basis.

Background and industry context

As one of the top five causes of occupational ill health, highlighted in HS2’s Health & Safety Strategy 2023[3] Hand Arm Vibration Syndrome (HAVS) is a health condition caused by the vibration from powered tools and machinery. Damaging muscles, nerves, joints, bones and blood vessels, it can lead to loss of feeling and reduced circulation in the hands and arms together with bone health conditions (See Figure 1). Regular or frequent exposure to hand-arm vibration, likely to occur when the use of vibrating tools is a regular part of someone’s job, can lead to permanent long-term ill health. HAVS can be prevented, but once the damage is done it is permanent.

The Health and Safety Executive (HSE) in the Control of Vibrations Regulations 2005 [4], states ‘where a risk cannot be eliminated an employer needs to reduce the exposure to as low a level as is reasonably practicable through organisational and technical measures.

Often on site a power tool will be used in conjunction with another static metal tool such as a spanner, for example when tightening bolts to erecting a scaffolding tower or metal structure. In these situations the vibration source is coming from the power tool but is transferred through to the static metal tool and to the operator’s hand. By adding a rubberised/insulated sleeve to the static tool minimises the transfer of vibrations to the operator’s hand and benefits any worker working in this way on site, which is a daily occurrence on a construction site.

While constructing the Batching Plant on the A41 in the Aylesbury area, it was observed that there was a need for thousands of bolts to be manually inserted. These bolts were tightened with a metal spanner and a battery-operated torque wrench which produced vibration. More than 2,500 bolts were needed, potentially exposing workers to regular and excessive vibration

Approach

Concerned that our contractor’s operatives were potentially being exposed to HAVS, EKFB asked for further support from our occupational health provider People Assets Management (PAM) to measure the HAVS’ exposure level and suggest ways of removing or reducing the exposure. PAM provided an occupational hygienist and tests were carried out on the operatives to find out the current exposure levels.

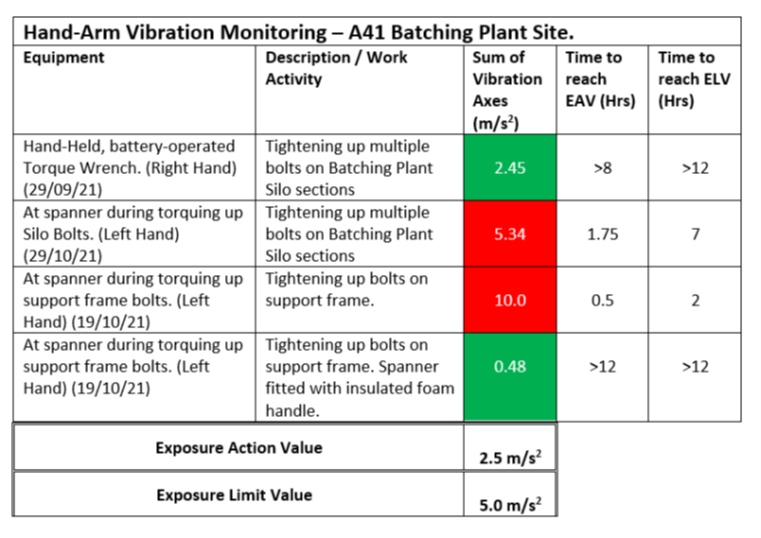

The occupational hygienist used a professional Pulsar HAVS meter connected to the spanner, firstly without the rubberised sleeve and secondly with the added protection of the rubberised sleeve. Results are detailed in Table 1 below.

Table 1 – Hand-Arm vibration Monitoring

The tests showed that the vibration levels in the hand holding the spanner (left hand) had an increased vibration exposure rather than the hand holding the vibrating torque wrench (see Figure 2). The exposure levels measured were double the HSE’s accepted HAVS upper exposure value level of 5m/s2 when tightening the support frame bolts (10m/s2), so there was an immediate need to remove or reduce the risk to workers.

A simple and cost-effective solution in the form of a rubberised/insulated sleeve was added to the spanner handle costing approximately £1.50 per spanner, to see if this would reduce vibration exposure since there was no design solution available. This idea was derived from the collected experience of the people involved on site and the knowledge that some tools (e.g. hammers) often come supplied with a ready-made rubberised sleeve (see Figure 3). The added sleeve did not restrict work from carrying on normally.

Outcomes

By adding the rubberised/insulated sleeve to the spanner handle, the results of the tests with the additional protection showed that the vibrations then being received were only a 20th or 5% of those without the additional protection – 10m/s2 unprotected down to 0.48m/s2 protected.

Data from the tests was as follows.

Without protection:

X= 3.80 Y= 6.35 Z= 6.74 Overall = 10m/s2 (doubled the upper exposure value limit)

With protection:

X= 0.37 Y= 0.19 Z = 0.23 Overall = 0.48m/s2 (reducing exposure to 5% of that without

the added protection)

(X axis = forward/back, Y axis = up/down, Z axis = side to side)

Learnings and recommendations

The project manager of the batching plant contractor agreed to use the new method on the erection of the remainder of the A41 batching plant and to adopt it to erect a further batching plant on another EKFB site. They also confirmed that this method would be used on its future projects worldwide. However, the adding of a rubberised sleeve to a static metal tool has many more applications on site, for example when erecting scaffolding or metal structures and in the erection of large plant (e.g. cranes) or in the repair of plant/machinery on site. These activities involve a large number of people on site comprising of approximately 24% of the total workforce (labourers, fitters, pipelayers, erectors).

This initial learning event raised awareness of HAVS across EKFB’s Aylesbury area and since then HAVS medical assessments have been introduced for our operatives and Reactec’s HAVS monitoring system, a leading HAVS monitoring supplier, has been introduced on AA sites. The Reactec system allows us to monitor daily HAVS exposure levels for all vibration tools being used on site for activities such as drilling, concrete trimming and scabbling, ensuring that the minimum exposure value level for each tool is not exceeded.

In addition, EKFB has produced HAVS support materials to use at inductions and briefings and has therefore created a true learning legacy in relation to HAVS awareness and control.

Conclusion

HAVS is a major health risk on most construction sites, putting at risk over two million people in the utility and construction sectors in the UK. However, because its effects are initially hidden and longer-term it can be easily overlooked or ignored. In later life its effects can be life changing, irreversible and permanent.

The potential HAVS risks on the A41 batching plant were more obvious because of the volume and intensity of the task over a period of 38 days. It led to an increased awareness of HAVS in EKFB’s Aylesbury area and across other EKFB sites, moving on to HAVS medical assessments and the use of Reactecs’ HAV’s monitoring system.

HAVS is now, amongst other occupational health risks, much more of a focus on our sites with medical support and supporting materials provided by our occupational health team. This drive has created a true learning legacy which will continue throughout the duration of HS2. At risk are 24% of the workforce on an HS2 site, labourers, fitters, pipelayers, erectors, who use power tools and static metal tools during their working day. This equates to approximately to some 7,200 people across HS2 sites as a whole.

Acknowledgements

Mark Holdsworth, Occupational Hygienist, PAM Medical Services.

Carla Santigosa, Project Manager, E.I.M.E. Alison Crawley, Head of Occupational Health, EKFB.

Bill Strachan, SHW Manager, EKFB.

References

[1] Health and Safety Executive “Hand-arm vibration at work”. Accessed 31 July 2023.

[2] legislation.gov.uk “The Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013”. Accessed 31 July 2023.

[3] Gov.uk Corporate report “HS2 Health and Safety Strategy 2023” . Accessed 31 July 2023.

[4] Health and Safety Executive, “Control of Vibration at Work regulations 2005” . Accessed 31 July 2023.

[5] Reactec HAVS – Hand Arm Vibration Syndrome. Accessed 31 July 2023.

Supporting Materials

As support material for inductions and briefings, EKFB has developed a short video.

EKFB has developed PowerPoint presentation for their designers and supply chain on how to design out the risk of HAV’s at the design stage. This has been shared with their principal designer ASC.

EKFB’s occupational health provider has provided a booklet which covers HAVS and its’ associated risks.

EKFB have also developed a toolbox talk for briefing site teams about the risks of vibration and HAVS.