CSjv approach to land quality, materials and waste

The approach that Costain Skanska joint venture (CSjv) took to meet environmental standards and requirements on High Speed Two (HS2) was highly successful and a result of excellent initial understanding and planning in the early phases of the enabling works. This paper focuses on land quality management, regarding which CSjv took the rare decision to create bespoke written procedures. These ensured consistency across the scope as well as clarity for stakeholders and the supply chain regarding what was expected and what would be delivered. The approach detailed in this paper can be applied to other projects and programmes on HS2 and within the wider industry. It will be of particular interest to those seeking to prepare strategies to mitigate potential risks rather than actual risks.

Background and industry context

High Speed Two (HS2) is a landmark project and one of the largest infrastructure projects ever undertaken. Its vision is to be a catalyst for growth across Britain, and an exemplar project as regards its approach to engagement with communities, respecting the environment and overall sustainability. The southern section of the Enabling Works Contract for Phase One involves a unique set of circumstances, and a once in a generation multi-disciplinary programme of works, all within a brownfield environment. A key challenge for the project given the location and scope of works was ensuring that the 95% diversion from landfill target was achieved, through maximising the reuse and recycling of excavated materials. This is a key challenge for the industry as a whole, with reusing waste being a key enabler to reducing carbon emissions and driving the sector towards Net Zero.

In terms of Environmental Management, the Enabling Works Contract is distinctive due to the specific HS2 Act [1] which underpins the planning regime. The HS2 Environmental Statement [2] sets out the baseline and predicted impacts that the Enabling Works Contractor (EWC), Costain Skanska joint venture (CSjv), must adhere to, and supports the HS2 Environmental Minimum Requirements (EMRs) [3] which detail the minimum construction standards and stakeholder commitments applicable to CSjv’s works.

Approach

The Enabling Works scope of works contained numerous pieces of works specifically relating to the management and remediation of land contamination in order to de-risk and remove constraints/uncertainties for HS2, leaving the sites in a condition such that follow-on HS2 contracts could begin works smoothly. This provided a substantial positive impact for the scheme. This scope included: significant ground remediation/reclamation at sites including Old Oak Common; fuel tank removal; management of groundwater contamination risks at the Brookwood Reburial site; and significant volumes of waste recovery including the crushing of over 160,000 tonnes of demolition arisings in aggregate for reuse on site.

As well as the specific scope above, the EWC carried out all other work scope whilst applying best practice with regards to land contamination, with over 40 work packages being assessed for land quality impacts. Of these, 30 have been subject to preliminary risk assessment, leading to 20 site investigations being completed, comprising 600 exploratory holes and 1000 chemical samples. This has led to the diversion of over 100,000 tonnes of excavated waste from landfill.

The Enabling Works was undertaken in accordance with the HS2 Land Quality Technical Standard [4]. This required the production of a bespoke Land Quality Management Plan (LQMP) in order to set out how the EWC and its supply chain would deliver the Land Quality Assessment and mitigation requirements of the contract. It also detailed how potential land contamination impacts and effects of the Enabling Works Contract should be managed in accordance with relevant legislation, regulations and HS2 project requirements. The LQMP is shared as a supporting document for this paper.

The way in which the Enabling Works Contract was procured meant that the scope of works for most if not all Work Package Areas was determined in advance of access to, or possession of, these sites. Land Quality Assessment is typically an iterative, risk-based process whereby information is gathered progressively over time in order to build up a detailed picture of a site; in accordance with the principle of sustainability, any mitigation that may be required can then be designed around a specific development layout or programme. The approach to management of land quality on the Enabling Works Contract meant that the EWC often had to make ‘worst case’ assumptions as part of a preliminary Land Quality Assessment and prepare strategies to mitigate potential risks rather than actual risks. Accounting for these ‘worst case’ assumptions ensured that nothing was overlooked and that specific strategies could be developed on each site that made the risk smaller rather than bigger.

Outcomes and learning

Old Oak Common

The Old Oak Common (OOC) site is a former rail depot. The site will be redeveloped as a HS2 underground station and major transport interchange. In order to clear the ground for this construction work, it was necessary to undertake a programme of mass earthworks, to clear buried constraints/foundations, remove small quantities of gross contamination, and provide a re-engineered development platform which was verified both geochemically and geotechnically.

Despite the extensive industrial history of the site, which has had over 100 years of previous use as a railway depot, the ground reclamation works were successful in delivering 100% of the general fill requirements from recovered site-won excavated materials. The materials were re-used in accordance with the CL:AIRE Definition of Waste Development Industry Code of Practice. 23,320m3 of excavated Made Ground materials were processed to create 6F2 to offset respective surpluses and shortfalls of these materials for the earthworks. Further to this, 260m-long storage depots and further smaller maintenance sheds were demolished and 160,000 litres of hydrocarbon containing liquids were removed from site.

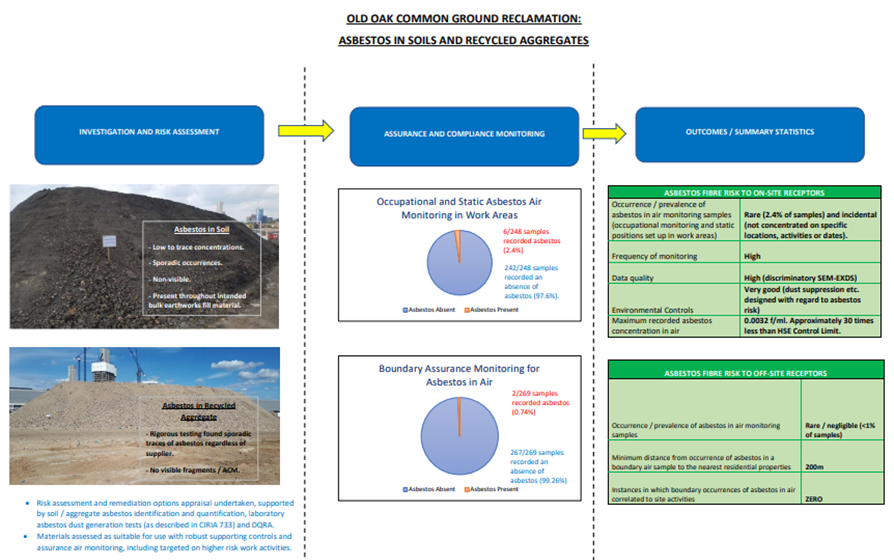

One of the primary challenges with this mass excavation and re-use was the presence of asbestos fibres in soil. In common with many brownfield sites, trace to low levels of asbestos were found throughout the Made Ground soils that were present across the site. This material was successfully re-used under a detailed asbestos control and assessment for fibre release and inhalation; occupational and environmental asbestos air monitoring for compliance and assurance purposes, comprising over 250 samples analysed for asbestos fibres with high sensitivity discriminatory quantitative techniques (SEM-EXDS); and over 250 boundary asbestos air monitoring assurance samples. This allowed asbestos-containing soils to be re-used as earthworks backfill safely and effectively in a highly sensitive urbanised environment, with robust supporting assurance and compliance evidence (see Figure 2).

On-site crushing and reuse of demolition arisings

A large proportion of the HS2 Enabling Works involved demolitions in and around Euston Station, London. These demolitions had to be completed in line with HS2’s contractual and environmental requirements, which stipulated for all imported aggregates to come from recycled sources wherever feasible.

Approximately 163,000 tonnes of materials arising from the demolition of buildings and structures have been transformed into aggregates. Out of this amount, a total of 148,000 tonnes were used on the Enabling Works Contract to create temporary vehicle access ramps, crane mats, haul roads and as backfill to structures and platforms, with 15,000 tonnes stockpiled on site for further recycling to facilitate the upcoming Main Works Civils Contract. An assessment carried out under four different scenarios has shown that the adopted solution has delivered a total of 1,983.42 tCO2e against the worst-case scenario involving separate removals of waste (i.e. unladen lorry to site and leaving laden) plus the production of virgin aggregates and deliveries to site. In addition, the wider environmental benefits included a reduction of fuel consumption by 1,431,342 litres, eliminating 36,000 tipper journeys from the local road network and significantly minimizing the effects on the local community. The crushing strategy also produced a financial benefit related to the removal of the need for waste removal and subsequent material deliveries to site, with a net cost saving to the contract in excess of £4.8 million.

Land quality management at St James’s Gardens (SJG)

The work at SJG involves the exhumation of over 40,000 bodies from an eighteenth- and nineteenth-century cemetery adjacent to Euston station. The primary land contamination challenges associated with this work were the presence of widespread Japanese Knotweed (JKW), and the presence of a small number of mercury-treated remains (mercury was historically used for various ‘medical’ purposes). In addition, the burial horizon was covered by a layer of Made Ground derived from various industrial sources, which had historically been placed as a cover layer over the remains, but itself contained elevated concentrations of various contaminants.

Initial surveys identified most of the JKW plants, but upon further investigation more plants were located within and outside of the boundary of the site. JKW contaminated soil has to be buried at a certain depth in a non-permeable membrane, meaning that there are few landfills able to accept this material and the costs are significant.

The project involved a number of closely interfacing activities within a relatively small area. These included foundation installation (for a large tent structure in which the archaeological works were undertaken), exhumations, tree removal and utilities work. Due to the complex nature of the project, support from a JKW specialist was crucial to ensure that the JKW was dealt with correctly. Careful planning and co-ordination, coupled with comprehensive training and site awareness ensured that all staff working in SJG were well aware of the risks and control measures to be followed. A detailed biosecurity plan was implemented from the outset of the works in order to prevent accidental transfer of JKW present on site. Strong collaboration, planning and communication between a multi-disciplinary team, and hand picking and segregation of rhizomes by specialist ecologists ensured the successful removal of this invasive species and reduced spoil sent to landfill (372.56 tonnes) by 8984.3 tonnes (96%).

A small proportion of the remains were found to have been treated with mercury. This risk was identified in advance of the exhumations through the land contamination risk assessment process (desk studies) and a discovery protocol was put in place. Mercury-contaminated remains were dealt with by a specialist trained team, who carried out a physical removal procedure for free elemental mercury, allowing this material to be collected from remains/within coffins and correctly removed from site as hazardous waste. Following the removal of free phase elemental mercury, the mercury-treated remains were segregated from the rest of the remains for specialist cremation.

Euston power signal box land contamination

As part of the University College of London (UCL) Hampstead Road building demolition, an area of suspected ground contamination within a raised slab was identified. Initial tests within the red area (Figure 5) highlighted high levels of asbestos. It was then thought that the entire grey area would be contain the same type of land.

It was decided to do a full site investigation in the grey area to determine if all of the material was hazardous. 12 trial holes where dug and tests carried out across the area, which highlighted that only the red area contained the asbestos. Following the results of the trial holes it was decided that the red zone and yellow buffer zone were to be removed as hazardous waste. The wider grey area was removed as non-hazardous. This led to a reduction in material classified as hazardous from circa 3000 tonnes to 200 tonnes, and saved an estimated of over £100,000 in removal and management costs.

Recommendations

It is rare for projects to have bespoke written procedures specifically for the management of land quality, but the benefits that this realised for the HS2 EWC have been to ensure consistency across all packages and also that stakeholders and the supply chain were aware of what was expected and what would be delivered. This is recommended for implementation on similar projects.

Conclusion

The Enabling Works Contract is a huge, complex project that is required to show exemplar performance in a range of topics including environment, sustainability, archaeology, construction and community engagement. The management of contaminated land across the project has been completed with these requirements in mind, with the solutions to the huge land quality challenges faced providing carbon savings, financial savings, benefits to the local community and a legacy for future projects to come. The EWC has delivered solutions that are not only compliant with best practice but are also compatible with the long-term aspirations of HS2 and wider environmental and sustainability goals, all whilst de-risking follow-on HS2 contractors to ensure they have the platform to begin works without land quality risks present.

References

[1] High Speed Rail (London – West Midlands) Act 2017 [cited 2021 Dec 6].

[2] HS2 Phase One environmental statement: documents. 2013 [cited 2021 Dec 6].

[3] Environmental minimum requirements for HS2 Phase One. 2013 [cited 2021 Dec 6].

[4] High Speed 2 (HS2) Limited. Technical Standard – Land Quality, Project document HS2-HS2-EV-STD-000-000027, HS2 Ltd, London, 2017.