Delivering first line of defence assurance – embedding a design team as a ‘Critical Friend’ within the contractor team

A comprehensive assurance process was developed for design and construction activities on High Speed Two (HS2) – with suppliers providing a first line of defence for a right first-time product. Contractor teams were required to deliver against a diverse and emerging scope of works to challenging programme constraints. To make the best design and CDM related decisions whilst meeting HS2’s assurance requirements, an innovative approach was taken by the Enabling Works South Contractor by engaging an independent and embedded team of engineering design professionals (the Lead Design Team (LDT) – a ‘critical friend’). The seconded team – unconstrained by specific deliverables – provided immediate, agile and flexible specialist input across the works; capable of deploying and reacting at short notice. The principles of safe by design were continually championed by the team, enabling the Contractor to achieve high quality assured deliverables. The ‘independence’ of the seconded team contributed to the success of the LDT who, where appropriate, challenged on engineering and design issues.

A relatively simple and successful idea, which could be replicated across other major projects.

Background and industry content

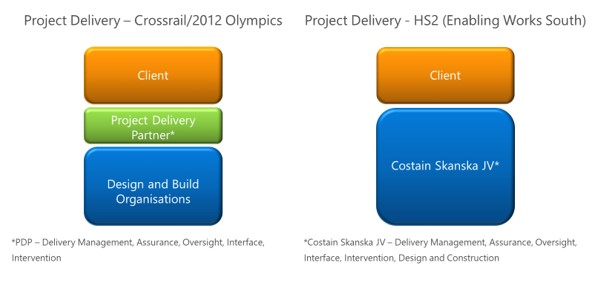

High Speed Two (HS2) developed a comprehensive assurance process for design and construction activities to deliver an innovative and ambitious regeneration programme. HS2’s delivery strategy differed from the model used on the Crossrail Elizabeth Line (London, UK) and for the London 2012 Olympics (London, UK).

Crossrail’s strategy included a Project Delivery Partner (PDP) to work alongside the various consultants and contractors. Tucker, in his paper on the Execution Strategy for Delivering the Crossrail Elizabeth Line1, indicates the PDP would undertake the day-to-day responsibility for delivery of the constituent contracts to time, to the desired quality and within the forecast cost, whilst delivering under the enabling legislation. The strategy for the London 2012 Olympics also incorporated a delivery partner. The Olympic Delivery Authority (ODA), a non-departmental public body of the Department for Culture, Media and Sport, was responsible for the delivery of Olympic venues, infrastructure and legacy. The ODA, in their 2015 2 report, describe how they appointed the delivery partner CLM – a consortium of CH2M Hill, Laing O’Rourke and Mace – to project manage the delivery of the Olympic Park and associated infrastructure.

The HS2 Chairman in his stocktake in 2019 3 describes how HS2 set themselves the challenge of exploring options to develop and implement the best possible delivery model to support their Phase One programme, from London to Birmingham (including the procurement and delivery of Enabling Works). HS2 developed a collaborative client organisation that relied upon its supply chain to directly assure and certify their work; with accountability for technical assurance placed solely upon the delivery organisation – removing any requirement for a delivery partner. Figure 1 shows a simplified pictorial representation of the different strategies adopted by Crossrail/2012 Olympics and HS2.

CSjv were appointed as the Enabling Works Contractor (EWC) to deliver the southern section of the HS2 Enabling Works Contract a multi-faceted, circa £700m contract to clear the way for the construction of HS2 across London. The EWC diverse and evolving scope included temporary and permanent works design and construction activities associated with demolition, utilities, archaeology, ecology, ground remediation, watercourse activities, highways, instrumentation and monitoring, surveys, foundations, tunnelling and structural works. EWC managed their scope through 90 plus separate design and construction Work Packages (WP) – segregated by geographical delivery parcels and managed by teams located in seven different hubs across the HS2 South route.

The EWC were the first line of defence for the delivery of an assured, right first-time product which included:

- The day-to-day management of technical risk, design management, construction management and technical assurance.

- Progressively submitting self-certified technical assurance evidence to HS2, in a manner sufficient to withstand scrutiny by internal or third-party audit.

- Providing internal controls to ensure safety and quality.

To support their challenging programme of delivering against a diverse and emerging scope of works, EWC identified the need for in-house design professional expertise to be embedded within their organisation to enable the best design and CDM4 (Construction (Design and Management) Regulations 2015) related decisions whilst meeting all of HS2’s comprehensive assurance requirements. EWC seconded a small, dedicated team of engineering professionals – a ‘critical friend’ – with extensive design, construction, assurance, CDM and delivery experience.

Lead Design Team (a ‘Critical Friend’)

The small Lead Design Team (LDT – a ‘critical friend’) consisted of chartered professionals and engineers, with typical experience ranging from 15+ to 35+ years’ of delivering across a broad range of high-profile infrastructure projects. The LDT provided EWC with an ‘independent’ (embedded and co-located) resource to assist in design integration; engineering assurance; managing risks; CDM overview; identifying, supporting, and resolving specific design issues; and providing HS2 with confidence that assurance for the project was being monitored and controlled. Where appropriate, to also test and challenge both EWC and HS2 to achieve best value project outcomes.

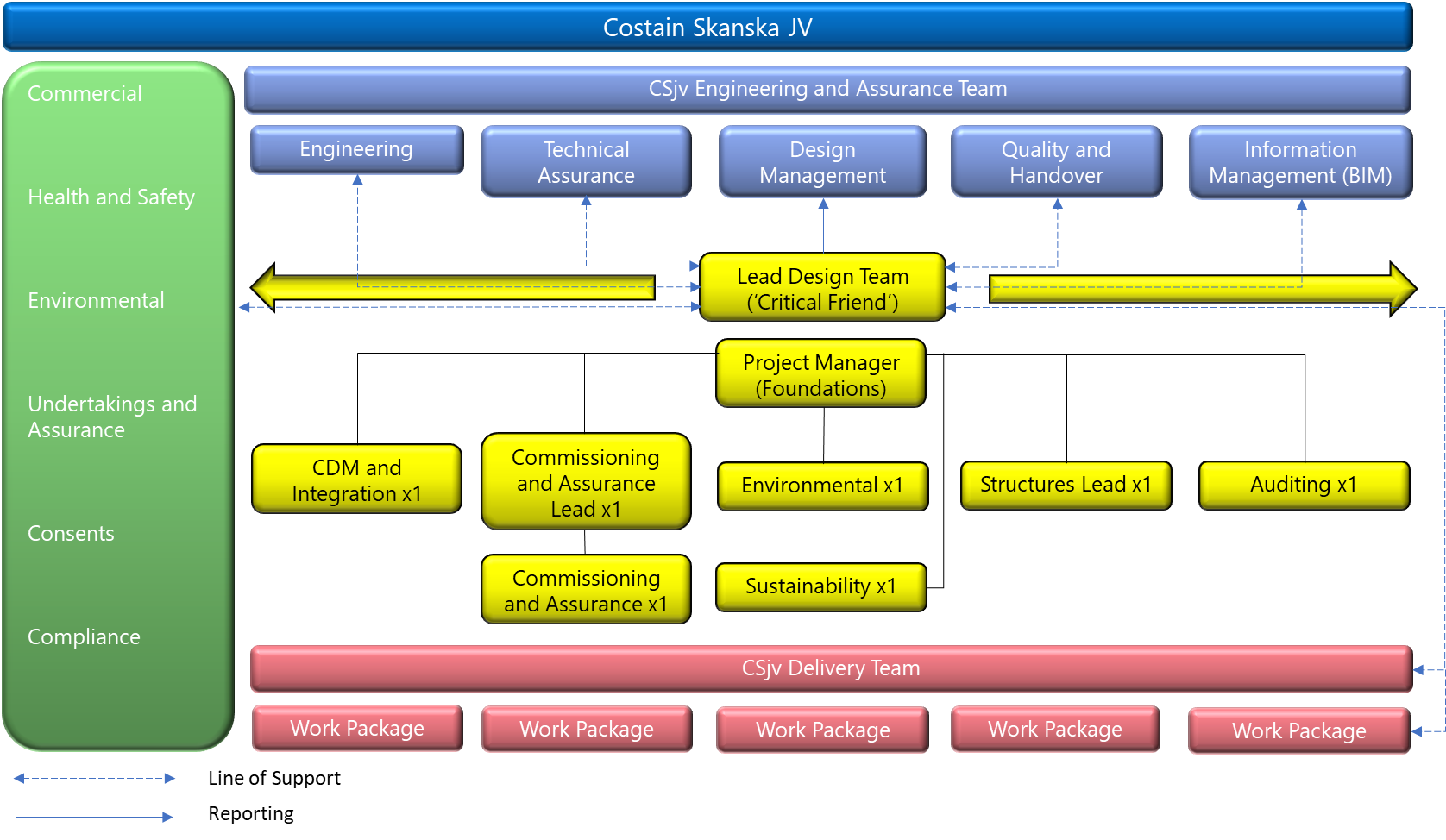

The LDT were embedded within the EWC’s Engineering team – reporting directly into the Principal Design Manager – and created to provide quick, agile and flexible specialist assistance across all aspects of the enabling works. The team provided direct and indirect support across the 90 plus design and construction WPs and to EWC’s core management organisation. Figure 2 shows the specialist skills provided by the individual members of the seconded LDT, and the team’s lines of support and reporting within EWC.

Strategic objectives

The strategic objectives for the embedded LDT were to assist the EWC in making the best engineering, design and CDM related decisions whilst meeting HS2’s assurance requirements.

Although unconstrained by specific deliverables; the team provided immediate and flexible specialist input across the EWC’s works – capable of deploying and reacting at short notice. Early and comprehensive roll out – through presentations, workshops and individual meetings with Directors – across all the EWC’s teams explained how the ‘critical friend’ would engage and support their works. The team focussed on early meetings with each WP Manager, and the leads of all Engineering and Project Support functions. To help establish the LDT regular ‘open’ workshops were held at each of the office hubs; where Package teams could meet and discuss issues and identify where guidance may be required.

Engineering support, by the LDT, was delivered through the team’s actions and responsibilities across the following strategic areas of the EWC works:

- Lead Designer

- CDM

- Design Intervention, Support and Oversight

- Technical Assurance

- Environment and Sustainability

- Miscellaneous Support

- Progressive Support to CSjv Engineering

Lead designer

HS2’s comprehensive series of Works Information (WI) for the delivery of Contractor assured works included WI600 5 ‘Contractor’s Design and Assurance’ – and introduced the role of ‘Lead Designer’. Relevant extracts from WI600 are included in the Appendix. As part of EWC, the Lead Designer role ‘certifies, on behalf of the Contractor, that the works have been constructed in accordance with the Contractor’s Design’. The EWC’s Lead Designer duties also include design verification sign-off as part of HS2’s Stage Gate process.

The Lead Designer requirements were fulfilled, across the Contractor, through experienced discipline and functional teams, well-developed plans, procedures, processes, and tools for the progressive technical assurance of design and construction activities. The LDT team worked with the Contractor to ensure full delivery of the Lead Designer duties, in accordance with WI600, and prevent gaps in their offering to HS2.

It should be noted that WI600 relates to HS2’s Enabling Works contracts and is replicated and captured across HS2’s main civil engineering works within WI300.

CDM

Primarily to ensure the EWC met their CDM responsibilities, with designs developed with safety and health fully considered. This comprised:

- Achieving CDM compliance across all design, construction, and handover (back to HS2).

Design intervention, support and oversight

To provide design and design management expertise and advice including:

- Critical oversight of designs to enhance the quality of design deliverables.

- Liaison, and involvement with WP teams during Single Disciplinary Design Reviews (SDR), Interdisciplinary Design Checks (IDC), and Interdisciplinary Design Reviews (IDR).

- Providing commentary on all design review packs. In addition to technical comments, the LDT also challenged the EWC’s designers to ensure solutions were safe by design.

- Chairing a significant number of design reviews on behalf of the EWC (including SDR, IDC and IDR).

- Engaging with Work Packages to technically support and positively intervene where required. Examples included:

- Granby Terrace Bridge (highways bridge over Network Rail lines) – Technical challenge and support.

- Tunnel Vent Shaft for London Underground (LU) – Commentary on supplier’s design, constructability, and support on achieving LU assurance.

- Noise Insulation Packages – Specialist technical advice to support package team.

- Priority Cycle Scheme – Challenge and establish the scope of works.

- Utilities – Technical audits of supply chain. Challenge team on approach to clash detection of existing and proposed utilities.

Technical assurance

Support the EWC across their technical assurance offering to HS2 including:

- Developing and implementing a Project Deliverables’ Checklist to reflect HS2’s assurance requirements.

- Structured guide and evidence checklist for delivery and assurance.

- Capture key activities for managing deliverables, gathering of evidence and understand deliverables for each stage of a project lifecycle.

- Included references to HS2’s original Works Information; CSjv Guidance (Procedures and Plans etc.); and the document numbers of examples illustrating what good looks like.

- Involvement in Technical Assurance project reviews and audits.

- Lead on and undertake audits of CSjv’s processes and procedures.

- Manage the EWC’s offering during HS2’s quarterly Technical Assurance Reviews.

- Review quality and completeness of submissions and mentoring of Package teams.

- Assurance Stage Gate Panel Member (as part of HS2’s L3 Stage Gate process). The L3 Stage Gate Certificate was issued at the end of each lifecycle stage, to certify that a product – completed and transferred to HS2 – was fully technically assured.

- Chair WP assurance reviews, to help the EWC identify and investigate the status of Work Packages in advance of moving toward the L3 panel.

- Support to the EWC’s Technical Assurance and Package teams seeking L3 certification.

- Attendance – along with other representatives of the EWC and HS2 – at the weekly L3 panels.

Environment and sustainability

To ensure the EWC met environmental and sustainability responsibilities through design, including:

- Engagement with the EWC’s Environment and Sustainability teams to:

- Review HS2’s environmental compliance process against the EWC’s scope of works.

- Develop the EWC’s Design Environmental Management Plan.

- Complete a review of technical sustainability standards and their adoption by Work Packages.

- High-level design gap analysis – specifically looking at materials, Circular Economy, Climate Change, Life Cycle Assessment and Materials Efficiency.

Miscellaneous support

Miscellaneous support included:

- Researching, developing, and authoring several EWC Engineering procedures and processes. Including, but not limited to:

- Technical Interface Management Strategy

- Procedure for undertaking design risk assessments

- Managing CDM Risks

- Management of Redlines and As-built Procedure

- Management of Contractor Assumptions

- Changes to HS2’s Technical Standards.

- Manage the response; review and assess the impact; and produce presentation materials regarding changes in HS2’s technical standards on EWC works.

Progressive support to EWC Engineering

Constant engagement with the EWC’s Engineering team, Works Packages and HS2 was facilitated through involvement in regular meetings, including:

- Weekly EWC Engineering team meetings.

- Weekly EWC Senior Design Manager meetings.

- Fortnightly EWC/HS2 Engineering Coordination and Assurance Performance Review.

- Representing the EWC at monthly CDM governance meetings chaired by HS2. The team shared experiences of managing and recording CDM risks with HS2 and HS2’s supply chain.

- LDT were co-located with the EWC Engineering and Assurance team.

Master Risk Assessment register – key risks

The LDT’s work on CDM compliance was a key element of their works and is captured in more detail by Harris et. al6 as part of HS2’s Learning Legacy.

The EWC needed to identify and understand the key CDM risk items across their £700m package of works. To ensure health and safety risks were managed consistently, the LDT team developed, compiled, and managed a master register of all Designers Risk Assessments (DRAs); Risk Assessments / Method Statements (RAMS) documents; and Health Hazard Evaluation and Mitigation Process (HHEMPs – relating to occupational health). The Master Risk Assessment register allowed all risks to be filtered to determine the key risks across the Enabling Works South Contract. In addition, the captured HHEMP’s provided a means of assessing specific occupational health risks identified during design, relevant to the Work Packages, and how they were to be managed during construction.

Throughout the works, the LDT provided a continual appraisal, to the EWC and HS2, of the key findings from the Master Risk Assessment register. The register was regularly updated with DRA’s and RAMS, including the ongoing development of risks, risk ownership, mitigation measures, and the close out and transfer of residual hazards. Feedback reports and monthly graphical data was used to illustrate and circulate details of key risks. Reporting included guidance on best practice and how the principles of prevention were employed by EWC designers, including occupational health. Reports also included guidance on how to manage and better communicate hazards, including what to and what not to include when considering risk. They also provided leading indicators of how the EWC could improve design and construction risk management across their works.

The LDT ensured the EWC’s CDM responsibilities were communicated and understood across their teams, and within HS2 – as Principal Designer.

The LDT’s wrap-around guidance included writing design risk assessments; through to residual risks – following completion of works – and how these are captured and recorded in the Health and Safety file for handover to HS2.

Lessons learned and successes

Secondment vs Professional Services Contract

In using an external organisation to provide the design skills and experience required for the role of ‘critical friend’ – the method of procurement proved fundamental to the success of the LDT. From the outset the EWC considered the following requirements and challenges critical for the Lead Design Team:

- Design professionals with experience and expertise to support the EWC.

- Team to be fully embedded within the EWC.

- Difficult to define a set of deliverables linked to a programme.

- Avoid ‘heavy’ contractual administration or governance.

- React to ‘current’ issues where support is required – potentially at short notice.

- Reach back for specialist advice and support.

- Quarterly achievement reporting of objectives – to help manage resource and workload; and identify areas of historical and future involvement.

- Co-located with Engineering Management leads – enabling early input into evolving issues.

These requirements were satisfied through seconding a team of design professionals into the EWC. A secondment was considered to limit contractual and commercial risks to all parties when compared to a ‘traditional’ Professional Services Contract (PSC). The EWC’s requirement for agile and flexible support would be difficult to achieve within a rigid contractual framework of defined deliverables and programme constraints. A PSC required more comprehensive governance, a detailed understanding of scope and change, programme, and variations. These risks, associated with an evolving scope, were more readily managed and resolved through a secondment. It is important to note that secondments prevent Professional Indemnity (PI) claims against the secondees parent company – however, the LDT activities were not typically of the type where PI would be called upon to remedy potential issues. For the duration of the secondment the team were fully embedded within, managed by, and represented the EWC.

The use of secondments, when compared to similar works secured under a PSC, limit off site and head office management needed from the parent company. Indicative fees estimated by EWC suggested the seconded LDT were approximately 10% to 20% less than the equivalent PSC fees for a similar resource.

Swift and agile deployment

The secondment provided the flexibility and agility needed by the team for swift deployment of resource when and where required. EWC quantified the monetary value of the team’s rapid mobilisation to evolving issues as follows:

- During their works the EWC employed approximately 250 direct staff working at any one time, approximately 5 staff per active WP.

- There were significant unknowns due to emerging scope on HS2’s Enabling Works South.

- Design or technical issues potentially led to Packages working inefficiently, for a limited time, until resolution was achieved. For example:

- During a delay, a WP working at 80% efficiency would approximately equate to the loss of one full time employee.

- Based on an average hourly rate of £70, inefficient working may equate to around £560 per day.

- PSC governance, instruction and staff availability may take circa 20 days between the initial request, contract negotiation to mobilisation. Effectively 20 days of the affected WP working at 80% efficiency would equate to approximately £11k+ (20 days at £560 per day).

- The seconded team could deploy quicker to limit delays and reduce this expenditure.

CDM

Through the Master Risk Assessment register, the EWC was able to understand and focus on their top risks; could share best practice across WP teams and their supply chain; enabled collaboration between design and SHE teams; use collected data to identify occupational health risks; provided confidence to the Principal Designer (HS2) of risk management; and demonstrate how the principles of prevention were implemented.

Through lessons learnt and knowledge transfer this approach was successfully adopted and established within SCSjv on other HS2 (South) works. CSjv made significant efforts, in conjunction with the Skanska Costain STRABAG Joint Venture (SCSjv), to communicate well established and successful procedures – including the identification and sourcing of suitably qualified and experienced resource.

Following the combined intervention of the LDT and Design teams, CSjv successfully initiated and completed a comprehensive refresh and roll-out of CDM training across their staff.

Design intervention, support and oversight

Some examples of positive design interventions and issue resolution addressed by the ‘critical friend’ team during design reviews included:

- Challenge to Utilities and Survey teams to consider developing the 3D utilities string line model – which mapped known existing utilities for CSjv’s permit to dig approval – into a 3D volumetric model. The 3D volumetric model, for existing utilities, was then overlaid on to the 3D volumetric design model; with potential clashes identified and modified before construction works commenced – minimising delays and abortive works on site.

- As part of a design review, for the reinforcement design for bored piles the detailed design indicated the use of cranked bars located at the pile head. The use of cranked bars would have prevented the pile cage being lowered into the bore during construction.

- Early specialist piling contractor involvement to validate the construction methodology and pile diameters proposed during the design of hard/firm secant embedded retaining walls.

- Ensure design optioneering and early decisions leading to a specific solution were fully assessed to understand, minimise, and mitigate project and health and safety risk.

- Support design packages to ensure they had understood, and captured, HS2’s requirements within their works. For one design package, the LDT produced a timeline of key contract information – including but not limited to undertakings and assurances with HS2 and the local council; Work Package instructions; aspirations from third party stakeholders; the designer’s terms and conditions; environmental requirements etc.- to confirm how the works had evolved and to establish an agreed scope of works.

Technical assurance

Successes related to technical assurance included:

- Project Deliverables Checklist rolled out across the EWC.

- Checklist used to provide details of essential and non-essential assurance evidence.

- Assess the status of Work Package deliverables.

- Includes TA Process Maps for Design, Construction and Handover.

- Checklist used to inform, track, educate and highlight areas of potential intervention.

- Status review of Works Packages in advance of the L3 Panel. Enabling, streamlining, and unblocking of Stage Gates through involvement in L3 process.

- Coordinating EWC involvement in HS2’s Technical Assurance Reviews.

- All Corrective Actions managed and closed.

Recommendations

HS2’s delivery strategy required their supply chain to directly assure and certify their own work; with accountability for technical assurance placed upon the delivery organisation. As the first line of defence for the delivery of an assured, right first-time product – the ‘critical friend’ was successfully mobilised and embedded to provide agility and experience to support the EWC works.

The ‘independence’ of the seconded team – as an external consultant – contributed to the success of the LDT role and were able to challenge, where appropriate, on engineering and design concerns.

The Lead Design Team successfully provided in-house design professional expertise to the wider CSjv Engineering team and Project Support functions to help make the best design related decisions whilst fully complying with the requirements of CDM and meeting HS2’s assurance requirements. The LDT were an experienced team of design professionals, successfully embedded within and enabled by the EWC to support their activities.

A relatively simple and successful idea, but one which could be easily replicated across other major projects.

Acknowledgements

Acknowledgements to the hardworking staff of the Costain Skanska Joint Venture particularly:

- Andre Stockbridge, Head of Engineering.

- Engineering and Assurance team.

- Design team and Design Managers.

- Work Package Managers and their teams.

- Project Support functions.

Also, to those members of the Lead Design Team, seconded from the Mott MacDonald Group, for their diligent and focussed work.

References

- Tucker B. The execution strategy for delivering London’s Elizabeth Line. ICE Journal. 2017

- Department for Digital, Culture, Media & Sport and Olympic Delivery Authority. Final report for the Olympic Delivery Authority (2006 to 2014). GOV.UK. 2015

- A Cook. HS2 Chairman’s stocktake. GOV.UK. 2019

- Health and Safety Executive. Construction (Design and Management) Regulations 2015. HSE Books. 2015

- HS2. Enabling Works WI0600 Design and Assurance. 1E001-HS2-DR-ITT-000-000047. p. 5 & 8

- D Harris, I White, M Ridley. Health and Safety by Design: Managing risk on HS2’s Enabling Works South. HS2 Learning Legacy. 2021