Delivering major highway works at Birmingham Interchange Station for the HS2 Phase 1 Enabling Works Contract – lessons learnt from design

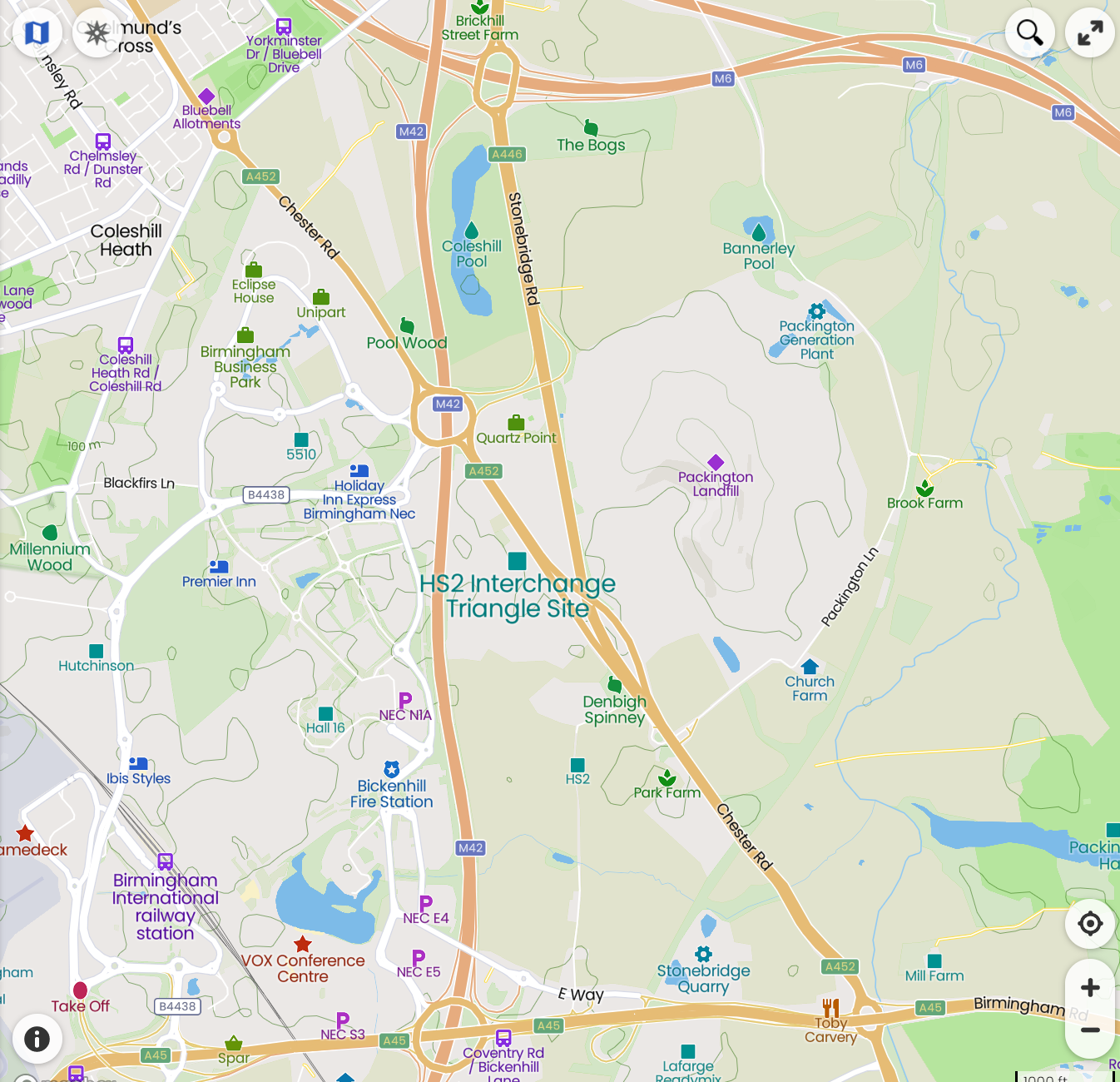

The HS2 Interchange station is the proposed new parkway station for High Speed Two (HS2) to be located in Solihull, West Midlands. Situated within a triangle of land bound by the M42 and the busy A45 and A452 trunk roads, the Interchange station will be connected to the National Exhibition Centre (NEC), the Birmingham International railway station and Birmingham Airport by a people mover. Within only 38 minutes from London via the new high speed railway, the Interchange station will become the new gateway to the West Midlands and the North. In September 2017 HS2 Ltd appointed the Laing O’Rourke Murphy Joint Venture (LMJV) to carry out major highway diversions and new bridge constructions to make way for HS2 and facilitate access to the new station. This paper discusses some of the challenges faced by the design team in delivering these works. It addresses how the scope of works including the proposed highway layout developed from the one presented at tender award to the final one which sought to address several safety issues and technical constraints while addressing some operational concerns from key stakeholders. The requirement of the HS2 Phase One Act [1]to obtain consent and approval from the highway authorities proved to be one of the major challenges of delivering this work. The paper discusses how adopting a collaborative and proactive approach ensured that the three highway authorities affected by these works were onboard with any changes introduced during the development of the design. The paper also provides an insight into how HS2 Ltd’s innovative approach to technical assurance was carried out in practice. By taking a “hands off, eyes on” approach to technical assurance, the LMJV and their Design Joint Venture (DJV) were empowered to take key decisions which helped eliminate some of the decision-making bottlenecks that often afflict many major projects.

Background and industry context

The High Speed Rail (London – West Midlands) Act 2017[1] (the Phase One Act) received Royal Assent in February 2017 and authorised the construction of all works associated with Phase One of the proposed high speed railway. This included works to divert, realign, improve or construct new highways to enable the construction of the new railway line. The HS2 Interchange station (or simply Interchange station) highways package was the first major piece of work to be delivered fully under the new Act [1] powers. The manner of delivering works using the hybrid powers of the Phase One Act[1] differed significantly from how highways are usually delivered. Under the Phase One Act [1], HS2 Ltd was the nominated undertaker responsible for appointing the designers and contractors for the work, and thereafter granting all the technical approvals required to construct the works. Although most of the highways constructed under the Act would be handed over to highway authorities for ongoing maintenance and operation, highway authorities did not hold any formal role within the contract. Instead, highway authorities would be required to give consent to HS2 and its contractors before construction of any works could start. This case study shows how some of the Phase One Act provisions were carried out in practice.

Description of the works

Figure 1 below shows the highway layout before the Interchange station highways project was started. The so-called Triangle site was bound by the M42 to the West, the A45 trunk Road from Birmingham to Coventry to the south, and the A452 and A446 trunk roads from north Birmingham and M6 .

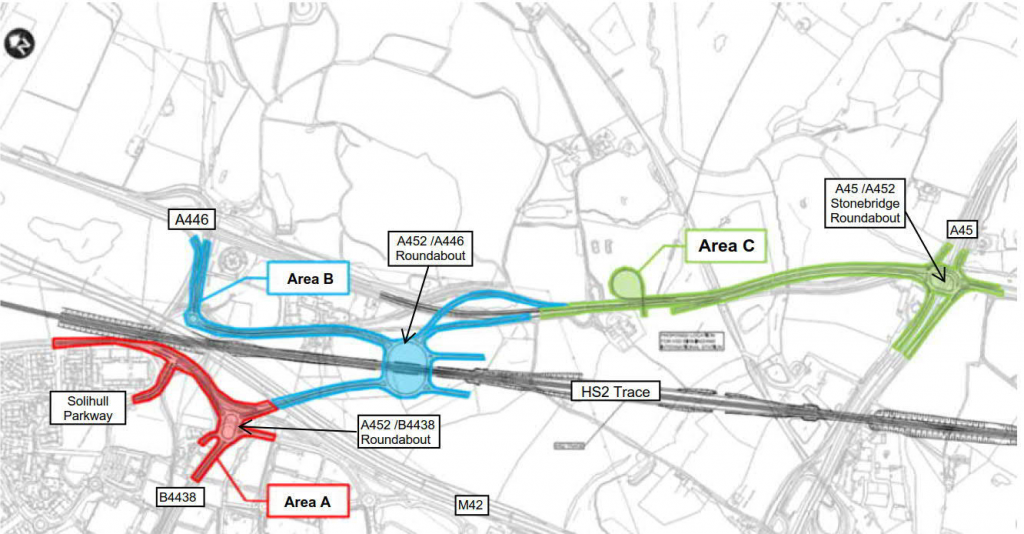

Figure 2 below shows the details of the highway works which formed the package of works required for the Interchange station highways. In order to manage the works, the package was further subdivided into three sub-packages called Area A, Area B and Area C.

Area A involved the removal of the existing A452 Chester Road roundabout, construction of the new Birmingham Business Park (Solihull Parkway) signalised T- junction and upgrade of the A452/B4438 roundabout;

Area B covered the A452 link road over the M42, the A452/ A446 Interchange station roundabout, A452 slip roads over and adjacent to the A446, A446 link road and the A446 roundabout. Area B also includes the first parts of the main station accesses.

Area C covered the construction of the Interchange station access(a subsidiary south-facing access), the A452 Chester Road realignment and widening and upgrade to A45/A452 Stonebridge roundabout.

The works also involved improving accesses to properties and businesses along the affected highways and the provision of cycleway facilities where possible. Under the Act [1], highway authorities had to give consent to HS2 Ltd before any construction could be carried out. It allowed only 28 days for the authorities to provide consent (or withhold it – but only on limited and specific grounds because the works had already been authorised by Parliament) otherwise consent would be deemed granted.

Managing the design stages

This project was part of the Enabling Works Contract (EWC) on the northern section of High Speed Two (HS2) Phase One delivered by the Laing O’Rourke Murphy joint venture (LMJV).

LMJV in turn appointed a design joint venture made up of WSP and Ramboll, referred as the DJV. Upon contract award the DJV reviewed the hybrid bill design and developed this conceptual design initially into a scheme design which formed an outline design required to start discussions with the consenting authorities. The scheme design was then further developed into detailed design which was taken for consent application and thereafter for construction. This paper focuses on the scheme and detailed design stages of the project.

Cognisant of the relatively short period that highway authorities had to review the design prior to granting consent, LMJV started a series of fortnightly workshops with each of the three highway authorities affected by the works namely Highways England (now National Highways), Solihull Metropolitan Borough Council (SMBC) and Warwickshire County Council (WCC). These collaborative design workshops were held to review design progress and incorporate any reasonable design adjustments that could be made within the Act [1] limits. The workshops also helped to establish the appropriate design standards and specifications to use for the works. During the early stages of design these workshops were discipline focused, targeting the technical specialists from each organisation.

Although the Design Manual for Roads and Bridges (DMRB) [2] is used for the design of all works on the Strategic Road Networks managed by National Highways (formerly Highways England), most local highway authorities also used it as their default highway design standard. However, some local highway authorities often have their own local modifications and standards which had to be agreed prior to the start of the works.

To manage the design, the LMJV Design Management team organised design review meetings at various stages of design maturity. Known as Inter-Disciplinary Design Review (IDR) meetings, these were held at 0% (Kick-Off), 50%, 75% and 100% design maturity. Initially, the IDRs were sent as open invitations, but it became immediately clear that they were over-subscribed, and it was difficult to get meaningful contributions from attendees. It became necessary to send select invitations to only the key people for each discipline from the client team (HS2 Ltd), the DJV and LMJV, as well as to the highway authorities and some key stakeholders. Managing the number of people attending IDRs was essential to ensure that input from key stakeholders was correctly captured and actioned. In addition, rather than solely rely on formal IDRs as a way of capturing design input and coordinating the design, LMJV also carried out progressive design development which included informal and ad hoc discussions with all the disciplines from the DJV and HS2 as well as highway authorities. This meant that issues were addressed as they occurred rather than being considered at the last minute when it was already too late, and hence costly, to make design changes. This approach was so successful for managing the highway packages that it was introduced for other workstreams, including non-highway packages.

A constant throughout the design reviews was the use of the federated model. A federated model is a building information model which combines models from different disciplines to provide a holistic view. The use of a federated model made it easier to communicate changes with all parties which minimised the chances of changes being missed by one or more disciplines.

Technical assurance

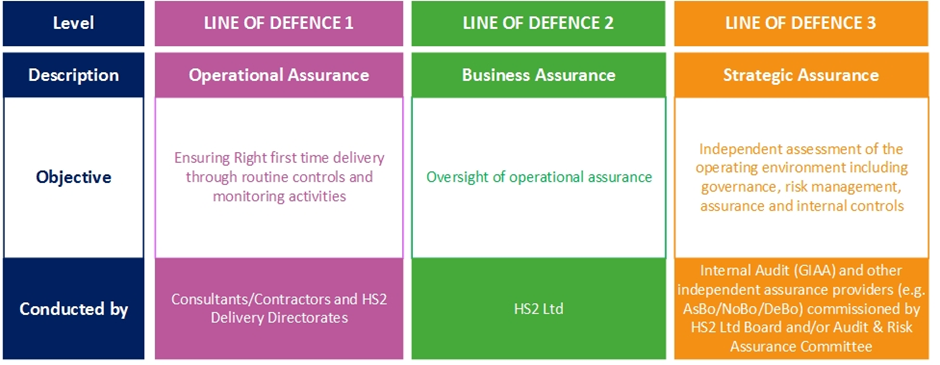

HS2 Ltd has introduced the three line of defence approach to technical assurance, giving power to its designers and contractors to assure their own work with limited involvement by HS2 Ltd staff or third-party assurance, except for higher risk work. The Three Lines of Defence model [3], is shown in Figure 3.

Applying the Three Lines of Defence Model

Level 1

LMJV and the DJV were responsible for assuring their own work to comply with the appropriate standards and satisfied the employer’s requirements.

Level 2

HS2 Ltd’s role was split into two. HS2 engineers who worked in the delivery team with LMJV and the DJV were responsible for ensuring that progressive assurance was carried out as well as to collate evidence that the contractor and designers were assuring their own work.

The Subject Matter Experts (SMEs) within HS2 provided another layer of Line of Defence 2 by carrying out random sample assurance as well as deep diving into higher risk areas.

Level 3

The third Line of Defence was reserved for very high risk work which was required by HS2 or other third parties due to their specialist nature, for example the technical approval of bridges over the motorways and trunk roads.

While this “hands off, eyes on” approach ensured that the HS2 supply chain was empowered to make their own decisions and that deliverables were not unnecessarily delayed in the bureaucracy of the approval chain, it was different from what most highway authorities are used to. In a traditional “Design and Build” contract the client organisation reviews and approves all the designs before construction. Where the client does not have internal expertise (or chooses not to use them), it often employs third party organisation to carry out design checks on its behalf. . To manage the ambivalence of the highway authorities on the reliability of a self-assured design, HS2 engineers and senior managers held meetings with highway authorities to explain how the technical assurance process worked. This included explaining the checks and balances that were put in the process which included carrying out random sampling of the work, ensuring that the first type of any submission was checked in full and reviewing of the higher risk areas of any submission. including any Departures from Standard [4]and Road Safety Audit [5] reports. HS2 also encouraged the highway authorities to fully engage with the design management team to ensure that all issues were addressed during the design stages rather than at the consenting stage.

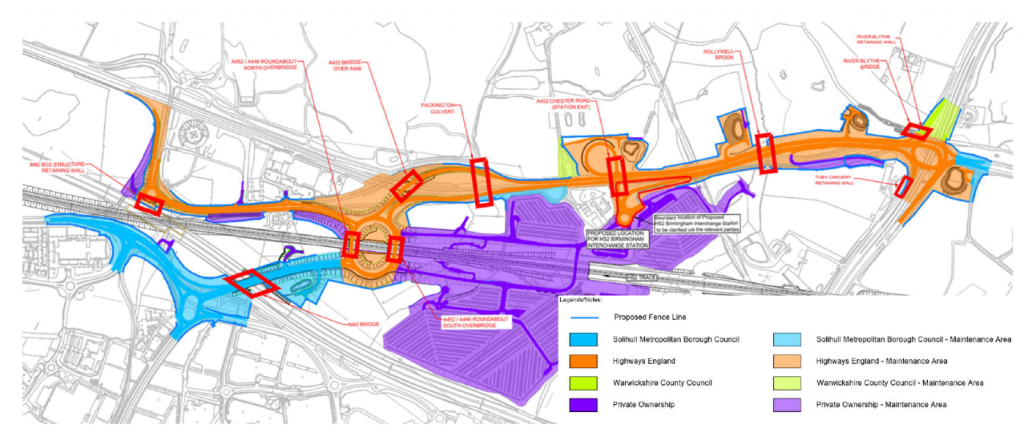

Another challenge for the Interchange station highways was that there were three highway authorities to liaise with. Highways England (now National Highways) were the main highway authority who owned and maintained most of the highways delivered under these works. However, some significant parts of the road network were to be maintained by SMBC, while a small section was to be maintained by WCC. A small number of roads were to be handed to private ownership, as shown by Figure 4. Dealing with three different highway authorities for the same package of work was a challenge as there were a lot of duplication of work and also some differences in approach which had to be tailored to each authority’s needs.

The other challenge came from the fact that this was the first major package of work to fully utilise HS2’s technical standards and guidance notes for scheme and detailed design. In order to take cognisance of the fact that most of the works on HS2 would be carried out using the Phase One Act [1] powers rather than the traditional Highways Act [6] powers, HS2 Ltd had produced a suite of technical standards, guidance notes, procedures, templates and other documents to be used as reference documents for the delivery of all works associated with the HS2 programme. All designers working on the project were required to familiarise themselves with the HS2 processes as they differed significantly from how highways are usually delivered. There was therefore a steep learning curve for design teams and HS2 engineers alike as they had to understand the scope of works while also unlearning some of the traditional processes, they had become accustomed to outside the HS2 programme. The HS2 standards and procedures had been produced based on experience from other similar projects such as Crossrail and Channel Tunnel Rail Link (now High Speed 1). While produced with utmost care, it became evident that some of the procedures could not be followed exactly as intended. For example, there was no procedure in place to deal with design changes which happened after consent had been granted, and also some of the procedures assumed that the programme of works would have no delays at all. Changes had to be made to the procedures to incorporate the lessons learn on this package.

Incorporating highway improvements for the highway authorities

The Phase One Act [1] works on the basis that only the works that are identified in the Act can be built, provided that consent from the relevant highway has been granted. Where works are not identified in the Act, these can be carried out temporarily provided they are within the highway boundary. No other works can be carried out, unless a separate agreement had been reached between HS2 and the relevant highway authority.

At contract award the Act authorised changes and improvements to be made to the surrounding highways to enable access to the new HS2 Interchange station. However, in the intervening period SMBC and a private company called the Urban Growth Company (UGC) had prepared a masterplan for new commercial and residential developments within the Triangle site. These developments necessitated improvements to the highway layout to cater for the additional traffic that would be generated. Through negotiations and provision for additional funding, HS2, SMBC, UGC and other stakeholders, changes were made to the highway layout and incorporated into the HS2 scheme. Although under the Act some of these changes would not have been acceptable, HS2 Ltd was flexible to accommodate the changes as they were for the greater good of the community. This flexibility of approach,using alternative powers and other delivery mechanisms , was a positive outcome for all parties.

However, incorporating changes into the HS2 schemes was not without its challenges. As design is an iterative process, it was often a challenge for the DJV to close out each stage of the design due to the constant feedback loop of comments and design change requests. Although these were mostly minor comments, making changes on a project of this size was time-consuming and meant that the design team spent a lot of time making changes rather than finalising the design. Also, not accepting any further comments from the highway authorities seemed to be working contrary to the spirit of stakeholder cooperation, and without a formal process to close out comments the earlier design stages did extend the timeframe. A formal process for agreeing design freezes was later introduced in the latter stages of design and this helped to the DJV to formalise the end of one design stage and move to the next stage more effectively..

Departures from standard

A departure from standard is required where the designer is not able to follow the requirements of a design manual or technical standard [4]. In the majority of cases departures were required due to physical site constraints. The Act defined the Limits of Deviation (LOD) within which all highway works had to be carried out. The LOD for the Interchange station triangle highways had been defined based on the concept designs produced for consultations prior to Royal Assent. At detailed design it became clear that more land might be required on some sections of the highways in order to allow for full visibility and stopping sight distance and in order to achieve horizontal and vertical alignment that were consistent with the design speeds for these highways. Unfortunately, purchasing more land beyond the LOD would be expensive, time consuming, require additional legislation and would also further delay the programme, so departures from standard had to be applied for. Further, on both the A45 and A452 there were existing accesses to commercial and residential properties and farms which led directly to the main highways. Under the current design standards these accesses would have needed to be closed and alternative accesses provided via side roads linking to roundabouts or junctions. This was not possible to provide in this location, so departures had to be applied. A total of 25 departures were identified in the Interchange station triangle and each departure had to be justified and mitigation measures provided. The cumulative effect of these departures and safety implications was also included in the assessment. A number of meetings were held to review the departures from standard, the federated model was again a common theme throughout, as it allowed the design team the opportunity to show hazards in 3D, to demonstrate visibility from certain locations and to show mitigations as a driver would see them.

These departures had to be agreed with the highway authorities, which added to the complication. Under the Phase One Act[1], HS2 Ltd was the nominated undertaker and therefore undertook all the usual client obligations, including the approval of departures. However, the public highways would be handed over to highway authorities after construction, so the highway authorities also had to ensure that they had also reviewed these departures and that they had no safety or technical concerns. HS2 Ltd had prepared a guidance note on how departures were to be approved, including a step which required evidence that the highway authority had been consulted on the departure before it could be approved. Not all departures had a detrimental effect. Sometimes departures from standard are required to introduce an innovative product, material or a new way of working. On the Interchange station highways, the DJV specified the use of around 10-20% recycled aggregate for pavement construction, which was a departure from the highway specification. The design team also proposed to use the so-called warm mix asphalt (WMA) instead of the traditional hot max asphalt. Using experience from other projects, the design team was able to demonstrate that asphalt mixed and laid at lower temperatures with certain binders added to the mix were just as effective as traditional hot mix asphalts. This approach, although not in the specification at the time, added positive environmental (around 8% CO2 emission reduction) as well as safety and productivity benefits to the project. This was agreed with the highway authorities and included in the works materials specification using the project departures process.

Road safety audits

Road Safety Audits (RSAs)[5] are carried out on new highway projects or improvement schemes to assess their road safety implications. They are carried out by experienced and accredited road safety auditors who are independent of the design team. The objective of the RSA is to minimise future road accident occurrence and severity once the highway has been built and is open to traffic. The RSA therefore forms a major part of the approval process. On most projects outside the Phase One Act regime the highway authority is responsible for approving the auditors and for authorising the recommendations from the road safety auditors to be accepted or rejected. On the Interchange station highways project, HS2 Ltd was responsible for this but had to ensure that the highway authorities had reviewed the RSA report and the responses to the report which was prepared by the design team. Another major hurdle faced by the design team was that around the time when this design was being progressed, the then Highways England changed the way Road Safety Audits were being carried out. From HD 19/15 [7] of the old DMRB standard to GG 119 [8] of the new standard, the reporting requirements for road safety audits were completely overhauled. These changes came midway between scheme design and detailed design, so a temporary arrangement was made to finish all outstanding scheme designs using the old standard but switch to the new standard for the detailed design stage. (This approach was also adopted for other design standards which were also being amended at this time (Highways England, 2019). Switching to new design standards midway through the design is costly and disruptive, so any switch to new standards was only made if there were significant safety and operational benefits, otherwise the existing design standards were retained.)

In order to reduce the period road safety audits were being reviewed, the design team decided to arrange for all audit responses to be discussed and agreed with the HS2 engineers before they were formally submitted. This significantly improved the efficiency of the process and led to closer working relationship between HS2, LMJV and DJV. To also ensure that the concerns of the highway authorities were considered the design team also sent informal copies of the audit reports to the highway authorities and brought their feedback back to HS2 Ltd to consider as part of the decision-making process.

Outcomes and learning

The concept of self-assurance was not popular with highway authorities at the start, but it worked well on the Interchange station highways, particularly due to the excellent skill and professionalism of the design team. Gaining trust of the highway authorities right from the start was one of the main reasons why it was possible to gain consent from the highway authorities without many technical challenges.

Understanding the provisions of the HS2 Phase One Act in relation to highway works was key to the successful delivery of the Interchange station highways package of works. LMJV and the DJV invested a lot of time in reviewing the various Act schedules and HS2 standards and other programme documents to understand what was required to get consent and approvals from the highway authorities. By assuring most of their own work, LMJV and DJV were empowered to make decisions at operational level rather than solely rely on the client’s review and acceptance.

Collaborative working was a major part of the successful delivery of these works. LMJV and DJV worked collaboratively with the three highway authorities and the HS2 team. This collaboration was not just limited to technical reviews of key deliverables such as Departures and Road Safety Audits, but throughout all the design stages. This was achieved through progressive design assurance and sharing of information throughout the design stage to ensure that key decisions were made in collaboration with all key stakeholders. This helped to improve the chances of getting consent granted well within the 28-day statutory period specified in the Act.

While understanding the Act requirements was key, it was also clear that flexibility by all parties was required to achieve project outcomes that were beneficial to all parties. Rather than strictly adhere to the design that had been deposited with the Act, through negotiation it was possible to incorporate design changes that reflected the late additional needs of SMBC and UGC with respect to other future developments within the Interchange station triangle site. The flexibility was also applied to HS2 Standards and guidance notes, which were refined periodically to reflect practical challenges associated with managing complex works using a type of legislative framework that is rarely used.

Managing change was also an important lesson learnt from the delivery of the Interchange station highways package. A clear process of managing design changes emanating from stakeholder engagement was introduced and this helped to stop the cyclical comments feedback loop which had hampered the early stages of the design.

Recommendations

The key recommendation from this project is that collaborative working with all key stakeholders is crucial to the success of the delivery of any project of this nature. The milestones for the project were not just limited to the technical delivery of the designs, but on the ability of the design team to get consent/approval of their works from the relevant highway authorities and other stakeholders. Therefore, collaborating with the stakeholders early in the design process was essential in ensuring that consents were not unduly delayed.

Although the project was carried out using the Phase One Act[1] which conferred powers on HS2 Ltd for most of the activities, some alternative arrangements had to be made to cater for circumstances not covered by the Act. Adopting a more flexible approach in the process which incorporated reasonable requests from highway authorities allowed third party consents to be determined in a more timely fashion.

Conclusion

The construction of the first phase of the works under this package is nearly complete (as of September 2021), with the highlight coming in August 2020 when one of the modular bridges was put into position over the M42 motorway during a weekend road closure possession [9]. Since then, several other highway packages have been successfully delivered across the Phase One programme. HS2 continues to update its standards and guidance to capture and reflect the lessons learnt across the project. LMJV and DJV have also started sharing these lessons with the Main Works Civil Contractors.

Acknowledgements

The authors would like to thank all members of the design team who worked on this record-breaking and award winning project. Special mention to Rob Hampton and Duncan Brooks from the DJV, Paul Day and Paul Christopher from LMJV, and Alastair Warnes, Chris Whitworth and Richard Adam from HS2 Ltd.

References

[1] The Stationery Office. (2017). High Speed Rail (London – West Midlands) Act 2017. London: The Stationery Office.

[2] Highways England. (2019, October 28). About the new Design Manual for Roads and Bridges (DMRB) and what’s new

[3] HS2 Technical Assurance Plan (eB reference number HS2-HS2-SA-PLN-000-000003)

[4] HS2 Guidance Note – Agreeing Departures with Highways England (eB reference number HS2-HS2-HW-GDE-000-000012)

[5] HS2 Guidance Note – Road Safety Audits (eB reference number HS2-HS2-HW-GDE-000-000004)

[7] Highways England. (2015, January). HD 19/15 – Highways England.

[8] Highways England. (2020, January). GG 119 – Road Safety Audit.

[9] BBC News. (2020, August 9). Engineers move 2,750-tonne HS2 bridge on to M42.

Supporting Materials

- WP005 – Birmingham Interchange Station – Enabling Works North Contract – Multidisciplinary Detailed Design Report for the BIS Highways – (1EW04-LMJ-HW-REP-Ns07-005000)

- Consents and Approvals Strategy – Permanent Highways (HS2-HS2-HW-STR-000-000001)

- Consents and Approvals Procedure – Permanent Highways (HS2-HS2-HW-PRO-000-000001).

- Technical Standard Roads – (HS2-HS2-HW-STD-000-000001)

- HS2 Design Review Procedure (HS2-HS2-DS-PRO-000-000002)