Development of an improved noise prediction model for HS2

HS2 uses noise prediction models for assessing the impact of high-speed trains in the surrounding environment and to inform mitigation requirements ([1] and [2]). The HS2 noise prediction model is an improvement to the methodology implemented in HS1, and employs the use of noise prediction tools as environmental prediction software. There is a need for these predictions to be updated to reflect progress in the design of the various railway subsystems, especially regarding high-speed rolling stock for speed higher than 300km/h.

Previously, it has been difficult to differentiate the noise impact of different rolling stock components in the environmental predictions. In particular, for speeds higher than 300km/h, the aerodynamic noise is known to be the main contributor to noise emissions during a train’s pass-by[3]. Accordingly, there is a clear requirement for improvements to the methodology used to accurately predict rolling-stock noise at these speeds.

This case study describes the development of an improved prediction tool to:

• Assess rolling stock pass-by noise from different design configurations and components, with a specific focus on high-speed transit (>300km/h)

• Calculate output compatible with large-scale noise prediction models (i.e. noise mapping software) used for environmental impact assessments.

Background and industry context

Noise prediction of future railway infrastructure is carried out by means of specialised software tools (e.g. CadnaA, SoundPlan, etc.) implementing various noise prediction protocols for railway noise.

The HS2 railway noise model is an improvement of the prediction methodology implemented by HS1[4]. The HS1 Method was developed in the 1990s and is comprehensively validated against measurements, nevertheless, it is intended for use up to 300km/h. The methodology has been revised for high-speed trains for the HS2 project [4]. The method uses the software tool NoiseMap, which is currently the only authorized software for implementing the HS1 and HS2 methods (references[2] and [4]). As for any noise prediction tools, NoiseMap requires a number of relevant input parameters regarding the rolling-stock noise sources and the track. It was identified that a gap exists in the knowledge required to accurately estimate and introduce those input data parameters into the software.

The current model is used for environmental impact assessment and implements a simple empirical approach for calculating sound propagation and screening. The model predicts typical noise indicators such as the equivalent continuous A-weighted maximum noise level (LAeq, representing the average sound level over a designated period) and maximum noise level (LAmax) surrounding the railway.

Alternative noise prediction methods exist and have been used in the past for high-speed railway lines[5]. However, these have limitations in the context of high-speed railway lines: limited train class definitions are available for high speed, and limited/inaccurate values corresponding to old rolling stock units. In addition, the methods are not able to inform the detailed design of rolling stock, for example when assessing the impact of different pantograph choices.

Currently, there is little guidance on the relative importance of the various noise sources observed in a high-speed rolling stock railway. The deliverable of Work Package 1 of the AERONOISE project, “Benchmark studies” [3], contains a state of the art review regarding rolling stock sources contribution for high-speed infrastructure. The initial assumption in the standard prediction approaches is that each type of railway vehicle has a fixed characteristic, which makes it difficult to separate the effect of the individual noise sources on the overall community noise exposure.

Pass-by noise prediction software is available to predict detailed pass-by noise levels from trains; at the time of writing however there are only two such products available: the output from the European “Acoutrain” project[6], and the commercial software “Train Noise Expert” [7], which is based on the Acoutrain approach. These prediction tools allow for individual sources to be defined on a virtual train and, using time-step analysis, the resultant sound pressure levels can be calculated for defined receiver positions. However, standard noise mapping software used for environmental impact assessments and strategic noise maps requires sound power levels to be defined in terms of line sources at one or more heights, and it is not straightforward to convert the results of the detailed predictions to inputs that can be readily used in the wider environmental noise predictions.

To improve upon the previously described limitations, through the HS2 Innovation programme, HS2 worked with engineering companies SENER Mobility, Institute of Sound and Vibration Research (ISVR, University of Southampton) and NoiseMap to develop an improved tool which focuses on:

- Assessing noise source levels at high speed

- Assessing rolling stock pass-by noise from different design configurations and components based on specific noise source estimation for high-speed transit

- Generating output compatible with noise mapping software used in environmental impact assessments.

Approach

This development originated from the observation that aerodynamic sources in high-speed trains are an important noise source for speeds higher than 300km/h, especially those located at the top of the train (e.g. the pantograph) because noise barriers and screens are less effective at mitigating them. Aerodynamic noise sources heavily depend on the train design which implies that better information of train performance is needed to conduct environmental noise prediction. An accurate environmental noise prediction is key to designing mitigation measures. Economies in the provision of noise abatement measures could only be achieved by improving the quality of noise assessments of future high speed rolling stock. With improvements to the definitions and localisation of noise emission sources, mitigation measures can be designed to the minimum necessary, which could result in significant cost and resource savings.

A fundamental approach towards accurate noise prediction of trains requires obtaining representative values of pass-by noise and apportionment among the different noise sources of the rolling stock. Once an accurate prediction of the pass by noise of any train configuration at a given speed is obtained, the input information or railway noise source terms required for environmental prediction software can be updated and lead to increased accuracy of environmental noise predictions.

To achieve the objective of obtaining accurate environmental noise prediction of high speed rolling stock and clear apportionment among the different noise sources of the rolling stock , it was decided to enhance and customise an existing tool developed specifically for rolling-stock noise source characterization. Train Noise Expert (TNE)[7] is a commercially available software prediction tool developed by the Institute of Sound and Vibration Research (ISVR, University of Southampton), implementing findings from decades of research in railway noise, and represents one of the best existing options to create the required output compatible with environmental prediction software.

By developing this tool, it will bridge the “gap” between detailed noise predictions for characterising rolling stock noise emissions and the railway noise source terms required for wider environmental noise predictions.

Proposed scheme for the new HS2 method and relevant parameters

The existing HS2 method for noise prediction is based on the software tool NoiseMap. The review of current methods and relevant parameters required by NoiseMap led to the definition of the required scheme for the new innovation project. The following steps define the general path that needs to be followed by this innovation project:

- Introduction of individual sound power values for each individual noise source following a common formula with adaptable parameters for each rolling stock.

- The sound power formula is speed dependent, and mathematical parameters can be obtained from test data, simulations or empirical approximations.

- Derivation of separated equivalent linear noise sources for each relevant sub-system of the rolling-stock, defined by individual geometric position of each noise source.

- For each rolling-stock configuration or design, sound power values will then be exported from the TNE software as a compatible file format.

- NoiseMap software will import the compatible file format, and generate environmental noise predictions for each rolling-stock design.

- The compatible file format will also be compatible with Datakustik CadnaA, another noise prediction method widely used in the environmental prediction industry.

Following the proposed scheme for the new prediction method, the next sections will briefly describe the specific developments performed within this innovation project for the most relevant parameters and aspects of the new tool.

Parametrization of elemental linear noise sources

Available test data from HS2, SENER Mobility and ISVR has been used to identify the geometrical position of elemental linear noise sources of a high-speed rolling stock. Additionally, typical values of sound power of each line source have also been identified. Specific test data obtained in 2018 by HS2 and SENER Mobility in a test site in Spain, (Las Inviernas), was used[8].

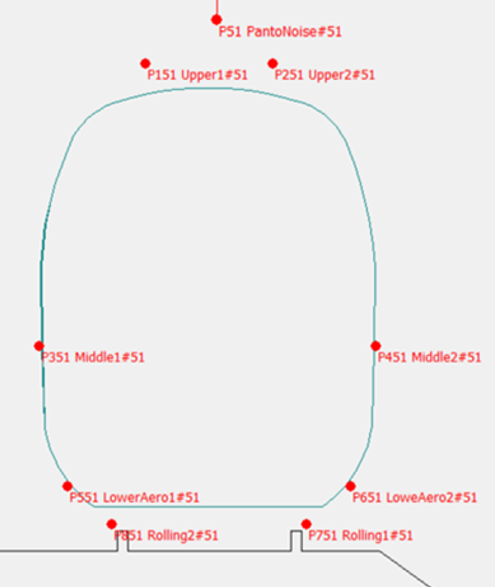

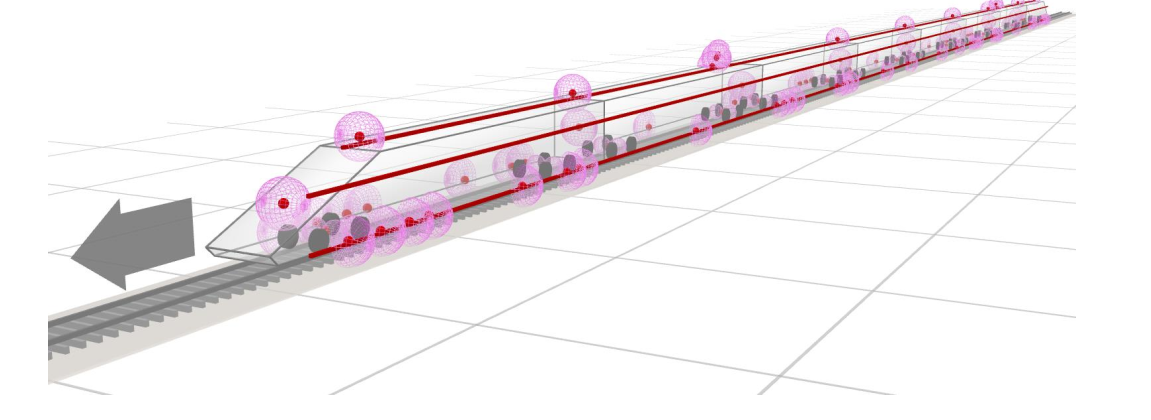

Figure 1 shows how the close perimetric noise measurements in a catenary portal were identified by HS2 and SENER Mobility in 2018[8] . These test results were used for the identification of geometrical position of elemental linear noise sources of the high-speed rolling stock. Results from these measurements and “Framework for Optimization of Multi-source Railway High Speed Noise Models Through Hybrid Methods Combining Acoustic Simulations and Close Perimetric Noise Measurements “ research[9] indicate that the noise sources of a high speed rolling stock can be simplified in five different noise sources, each at a different geometrical position with respect to the rolling stock. Out of these five noise sources, four sources are located symmetrically with respect to the rolling stock vertical axis, and the pantograph noise is located at the centre of the same axis, as shown in figure 2 and figure 3 below:

The TNE software allows the geometric positions of each individual noise source to be defined. Libraries of characteristics for different noise source types are available and may be chosen for each noise source defined by the user. The following types of noise sources are defined, with their specific parameters and sound power calculation methods:

- Rolling noise

- Prediction based on wheel/track parameters (e.g. rail roughness).

- Manual input of sound powers (with corrections for speed dependency), from test, simulation or empirical data.

- Aerodynamic noise

- Estimation based on the MANTICORE calculation routine (Modelling of Aerodynamic Noise from TraIns, a COmponent-based pREdiction, ISVR).

- Manual input of sound powers (with corrections for speed dependency), from test, simulation or empirical data.

- Engine/equipment noise

- Constant sound power values based on published examples (e.g. fans, motors, compressors).

- Manual input of sound powers (with corrections for speed dependency), from test, simulation or empirical data.

Verification/tuning of source sound powers

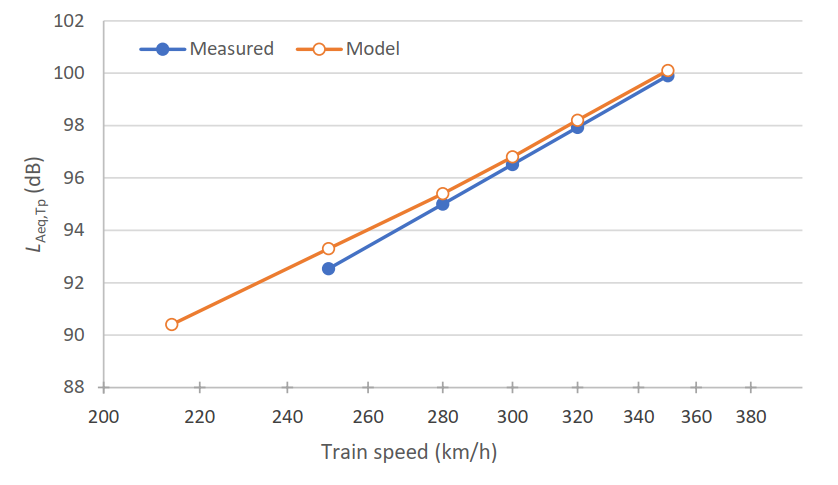

Measurements performed in 2018 by HS2 and SENER Mobility in a test site in Spain (Las Inviernas) were used to tune appropriate overall levels for aerodynamic noise sources and fit input parameters of TNE software[7]. A comparison of A-weighted equivalent continuous pass-by noise levels is presented in the following figure 4, at receiver positions situated at 7.5 m in the horizontal plane from the railway track, for different rolling stock speed:

The results show good agreement between model and measurements over the speed range considered, with some slight overprediction (1 dB) from the model suggested at the lower speeds. The slight overprediction between prediction model and experimental data can be attributed to the amount of damping present for the wheels used in the rolling noise model, and the amount of absorption provided in the bogie cavity region, which are both unknown for this set of experimental data.

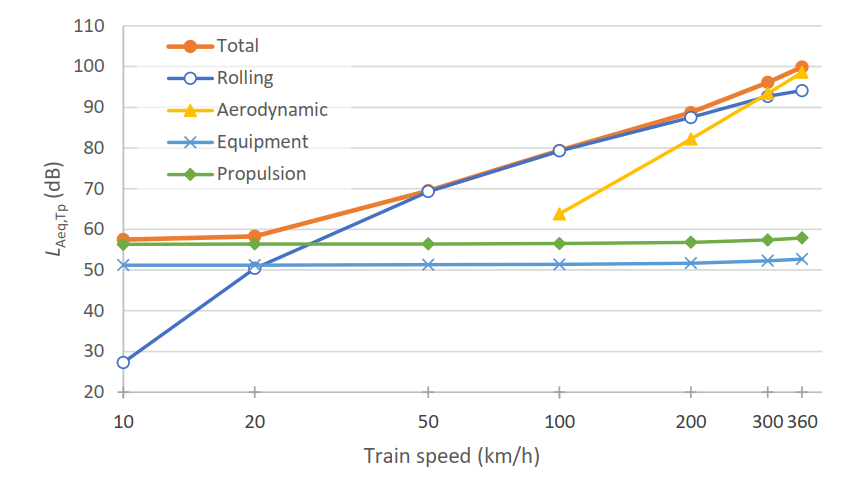

Overall A-weighted pass-by results of the HS2 train configuration are shown in figure 5. Partial contributions of each noise source are given, which give a clear understanding of which noise source types are the most relevant as a function of speed.

From results presented in figure 5, it can be observed that while rolling noise is clearly the dominant noise source for speeds lower than 200km/h, this trend changes from 200km/h with the increasing contribution of aerodynamic noise. Aerodynamic noise is the highest contributor to total noise from 300km/h onwards.

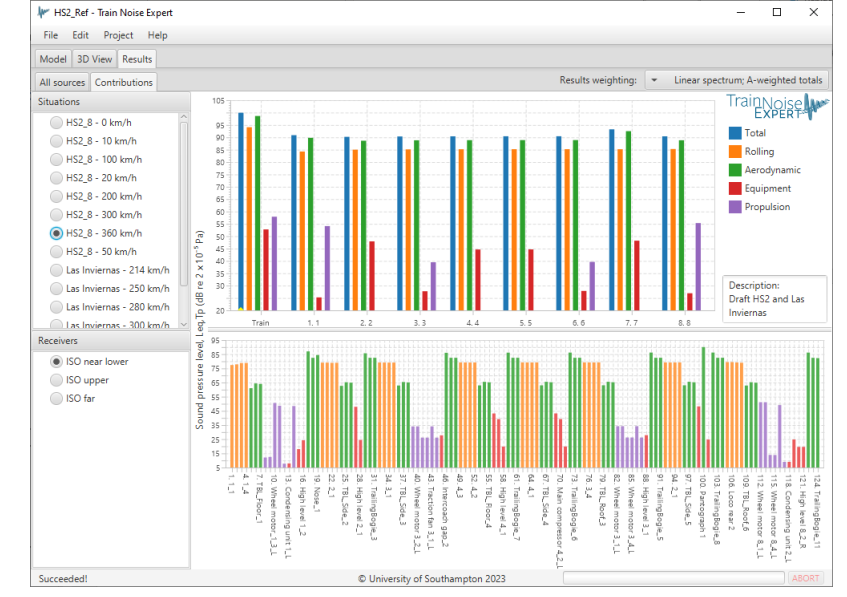

Examples of charts from the TNE user interface for the HS2 model are shown in the figure 6:

Software interface

Once relevant noise sources have been identified, defined by their geometrical position and their applicable sound power levels, this information can then be exported for use in environmental noise simulation software, such as NoiseMap and DataKustik CadnaA.

How the new improved tool will work

First, a user will prepare a train model in Train Noise Expert, with all appropriate source data, environmental details, and required receiver positions. The required train speeds must also be specified; for this project the following speeds are: 0, 10, 20, 50, 100, 200, 300 and 360 km/h. The rolling noise calculations are then performed to calculate the appropriate rolling noise terms. Then the external noise calculations are run to calculate the resulting sound pressure levels from all train sources at the defined receivers.

During this procedure for exporting, the contributions of each source in the model are apportioned to the closest defined heights for the selected noise map protocol. Train Noise Expert calculates the noise contributions from each of the source height categories and computes the corresponding sound power level per meter for each source height using calculated line source transfer functions.

Data is exported to CSV files in the corresponding results folder of the Train Noise Expert project. These can be opened for viewing with a spreadsheet program, and/or interrogated with software scripts.

- For each rolling-stock configuration or design, sound power values are exported from the TNE software as a compatible file format.

- NoiseMap software will import the compatible file format, and generate environmental noise predictions for each rolling-stock design.

- The compatible file format will also be compatible with Datakustik CadnaA, a noise prediction method widely used in the environmental prediction industry.

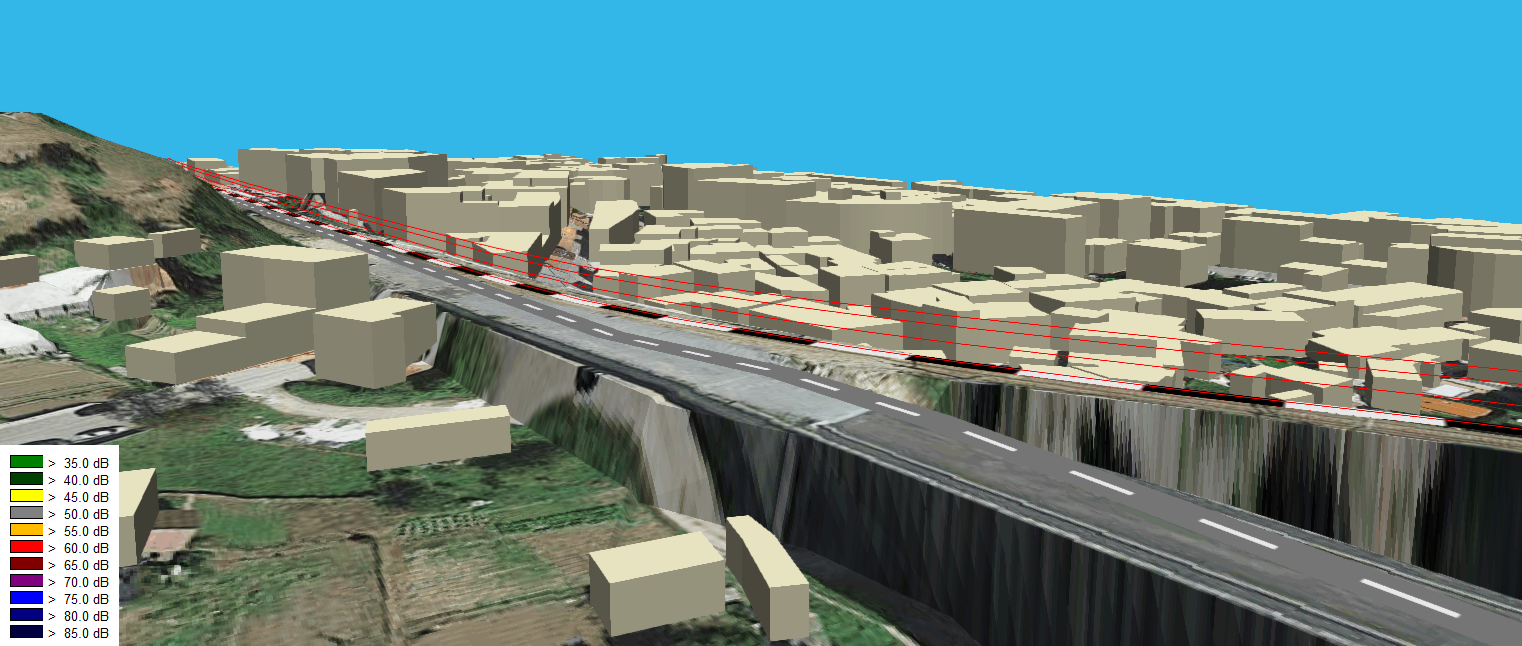

An example of Datakustik CadnaA model with imported data from the new tool is shown on figure 7.

Outcomes

The main outcome of this innovation project is the development of a new prediction tool which allows the assessment of high-speed rolling stock pass-by noise from different design configurations and components, and then generates outputs compatible with large-scale noise prediction models. A better understanding of the spatial distribution of noise emitting sources in high-speed rolling stock is obtained, and a clear comparison of different configurations of rolling-stock is possible. With this knowledge incorporated in environmental prediction software, noise mitigation measures such as barrier designs can be considered in the design of the infrastructure with a significantly improved level of accuracy. Overall, these outcomes will lead to a optimization in layout and design of noise mitigation measures, with reduced costs and lower environmental footprint, while maintaining adequate noise protection to the public.

Learnings and recommendations

The main learning during this project was to realize that a “bridge” between 2 kinds of acoustic modelling could be successfully established. One is the detailed acoustic modelling of the onboard noise sources of a train, which can be obtained in the specialised software TNE. The other is the detailed propagation model that can be obtained in the specialised acoustic software NoiseMap and CadnaA, which consider topographical and absorption characteristics, and also can model different types of noise barriers. Combination of both tools creates an opportunity to reach a new, improved level in accuracy of environmental noise modelling. This improvement can be useful for designing new railway infrastructure since the real source mechanism generated in the train can be considered with precision with this type of environmental prediction method. The increased precision in the modelling of noise from high-speed railway infrastructures constitutes the main legacy of the project.

Further learning observed during the project is that whilst several environmental noise prediction software packages are available to large scale noise mapping, there is no standard file format or protocol for importing data into these. It is recommended that work be conducted on developing a common, standardised file format to allow acoustic parameters to be readily imported/exported between these types of software.

Finally, whilst HS2 has developed its own prediction methodology for assessment of railway, it is recommended that additional research and development be conducted to define a new formal standard for railway noise predictions, which improves upon both the Calculation of Railway Noise (1995,)[10] guidance (the only existing UK-specific standard, which is very basic), and the CNOSSOS-EU prediction model[11] (which, whilst used for EU strategic noise maps, is not a requirement for the UK, and could be significantly improved with UK-specific terms, and additional source heights).

Conclusion

The result of the innovation project is a new improved noise model for high-speed trains. Data from this model can be imported by off-the shelf environmental acoustic software such as NoiseMap or CadnaA. Design of abatement measures using this new tool with the new improved model becomes more accurate and economical. Thanks to this innovation project, the environmental impact in terms of noise from future high-speed lines can be optimized.

References

- Hood, R.A. et al.: Calculation of railway noise. Proc. of the Institute of Acoustics 13 (8)

- High Speed Rail (London – West Midlands). Environmental Statement Volume 5: Technical appendices. Sound, noise and vibration methodology, assumptions and assessment (SV-001-000) / November 2013

- Aeronoise – Measurement and analysis systems to characterize the aerodynamic noise of high-speed trains – Technical Report: Benchmark Studies. Ed. Nº1, June 2022, UIC RAILWAY PUBLICATIONS.

- High Speed Two (HS2) Limited, 2017. High Speed Rail (West Midlands – Crewe) – Environmental Statement – Volume 5: Technical appendices, Birmingham: s.n.

- European Environment Agency, Environmental noise in Europe, 2020, Publications Office, 2020, https://data.europa.eu/doi/10.2800/686249.

- Nicolas FURIO (UNIFE), “Final Report Summary – ACOUTRAIN (Virtual certification of acoustic performance for freight and passenger trains)”, CORDIS Project 284877.

- Train Noise Expert software, software package developed by the Institute of Sound and Vibration Research (ISVR) at the University of Southampton. http://trainnoiseexpert.com/details/.

- G. Sica, J. Solé and P. Huguenet, “Pass-by noise assessment of high-speed units by means of acoustic measurements in a perimeter close to the train” IWRN13.

- G. Sica, J. Solé, P. Huguenet and O. Bewes “Framework for Optimization of Multi-source Railway High Speed Noise Models Through Hybrid Methods Combining Acoustic Simulations and Close Perimetric Noise Measurements” IWRN14.

- Calculation of Railway Noise, Department of Transport, July 1994, London:HMSO, ISBN 0 11 551754 5.

- Common noise assessment methods in Europe (CNOSSOS-EU), European Commision, Joint Research Centre, Stylianos Kephalopoulos, 2012.

Peer review

- Oliver Bewes HS2 Ltd