Digitising the chain of custody for Rebar: CARES Cloud

This paper is based on work to deliver Euston station as part of the High Speed Two (HS2) Phase one works, being delivered by the Euston Integrated Project Team (IPT) including Mace Dragados joint venture (MDJV).

It details findings from the trial of a new digital chain of custody system (CARES Cloud) for steel rebar at HS2 Euston station. The use of CARES Cloud provided significant productivity and efficiency gains when compared to traditional paper-based assurance methods. As well as enhancing the transparency of the supply chain it provided real-time tracking of rebar, its origin, improved product and quality assurance, improved accuracy of embodied carbon emissions and sustainability credentials.

The cloud-based platform provides an easy-to-understand digital dashboard to help project managers and contractors identify the quantities, product conformity and additional certification approvals status of rebar delivered to the site and could become a key part of a materials passport scheme on future projects. The digital architecture is transferable to other steel and wider construction-related products, providing an opportunity for the digital transformation of the built environment sector.

Background and industry context

In recent years, trust in safety-critical products has been seriously undermined by fake data scandals and major disasters such as the Grenfell Tower fire in London in 2017 which resulted in the loss of 72 lives[1]. Checking the truth of a product’s provenance has never been more important or needed than now – and reinforcing steel is one of the most safety-critical elements in any project. Structural engineers and contractors increasingly need to understand the environmental impact of their designs, particularly the carbon footprint of the materials they specify and use. Obtaining provenance and accurate embodied greenhouse gas (GHG) emissions data from Environmental Product Declarations for materials like steel has historically been a challenge.

To assure that materials are procured and supplied in compliance with HS2’s requirements, such as product conformity, responsible sourcing certification and BREEAM criteria[2] these requirements are included in materials specifications. In the case of rebar, one such certification standard that meets the specification is the CARES Sustainable Constructional Steel (SCS) Scheme[3].

Historically, paper-based certificates and delivery notes have been provided by suppliers to show the material supplied is certified to the required standards, and in the case of rebar, the validity of the chain of custody was [and still can be] checked and confirmed via the CARES website. However, it is a manual and time-consuming process to collate and check all the paper-based documentation, and there is often a time lag between the material arriving on site, and being able to obtain and check that the documentation is accurate and complete.

HS2 standards on materials sourcing and supply for steel are aligned with the Procurement Policy Note PPN 11/16[4] (superseded by PPN 04/23[5]), UK Government procurement guidelines. This necessitates the need to identify and report on the origin of steel used on publicly financed projects, and it is not always straightforward to identify this from paper-based documents.

Differences in systems, paper and digital formats, data collection methodologies and boundaries, levels of verification and quality requirements all create challenges but also add to the case for digital data transferable in common formats across the construction value chain. Digitisation of Global Warming Potential (GWP) data – Tonnes of Carbon Dioxide equivalent (CO2e) by Tonne of product – and its use to reduce GHG emissions is a key enabler of decarbonisation.

The CARES Cloud platform, first introduced in 2016 was developed to address and solve these real and urgent issues, bringing simplicity to a complex supply chain while restoring trust where it’s missing. By working collaboratively with stakeholders, the system tracks each batch of reinforcing steel from its point of origin to the construction site providing compliance and carbon footprint data plus sustainability credentials to achieve credits in BREEAM assessments.

Approach

Mace Dragados JV[6] partnered with CARES (UK Certification Authority for Reinforcing Steels)[7] and Digital Construction Solutions[8] to trial a digital chain of custody system for rebar on the HS2 Euston station project. The trial was undertaken throughout a value chain working on two of the early works piling packages and was supported by HS2’s innovation fund.

The trial aimed to provide a real-world test of the CARES Cloud on a major infrastructure project. This provides the methodology, tools, and system to enable real-time provenance data for steel rebar to be accessed. This included digitally authenticated CARES certificates of approval to the required product conformity and quality standards, and its carbon footprint data from verified Environmental Product Declarations[9] (EPD) for the whole supply chain.

CARES Cloud works by tracking each batch of reinforcing steel from its point of origin at a Steel Mill, through off-site fabrication processes and onward delivery to the construction site.

Standardised QR codes are used on bundles of rebar provided by each CARES-certified rebar manufacturer. A mobile App available for all commonly used smartphones is used to scan material that is received, used and delivered to the site, providing a digital record of the entire process.

A secure dashboard provides an overview of the product conformity approvals status of each bundle of rebar, ensuring it is of the grade specified, and a digital Product Material Passport of the rebar used, together with quality and responsible sourcing certificates, and the EPD for the actual material used. Figure 1 shows a sample dashboard format and access to digital certificates.

The specific goals of the trial were to:

- Achieve operational cost savings which are realised by implementing digital recording and removing paper pro-forma record sheets from the value chain.

- Improve speed, accuracy, and the quality of data throughout the value chain.

- Reduce recording time and logging of material deliveries – remove secondary data input.

- Establish a new industry standard for QR bar codes for manufacturers and fabricators.

- Prove the value and validity of the system, and gain buy-in from key stakeholders.

- Improve dissemination and exchange of data between different teams working on the project.

- Improve inclusivity, as digital recording in this way (scanning QR codes as opposed to manually inputting) can help individuals with different levels of literacy and learning abilities and those with visual impairments or significant motor skills issues.

- Support cross-programme innovation and knowledge sharing to establish new ways of using digital technology in the steel reinforcement supply chain.

- Improve accuracy of as-built project-based GWP data and as-built assurance evidence.

Outcomes

Well received by end users

Feedback from the supply chain demonstrates the tool was well received by users:

“Doing everything via the app has made the whole process a lot easier.” – Fabricator user

“All is still working well! I have now scanned and synchronised all cage deliveries. The app is easy to use. With regards to the Carbon and Tonnage, I believe this has been of value to the Client.” –Sub-contractor user

Delivered on all the goals set:

- 100% of steel reinforcement was delivered with a complete set of assurance records; all CARES certificates of approval; and complete carbon footprint data for all reinforcement manufacturers and fabricators.

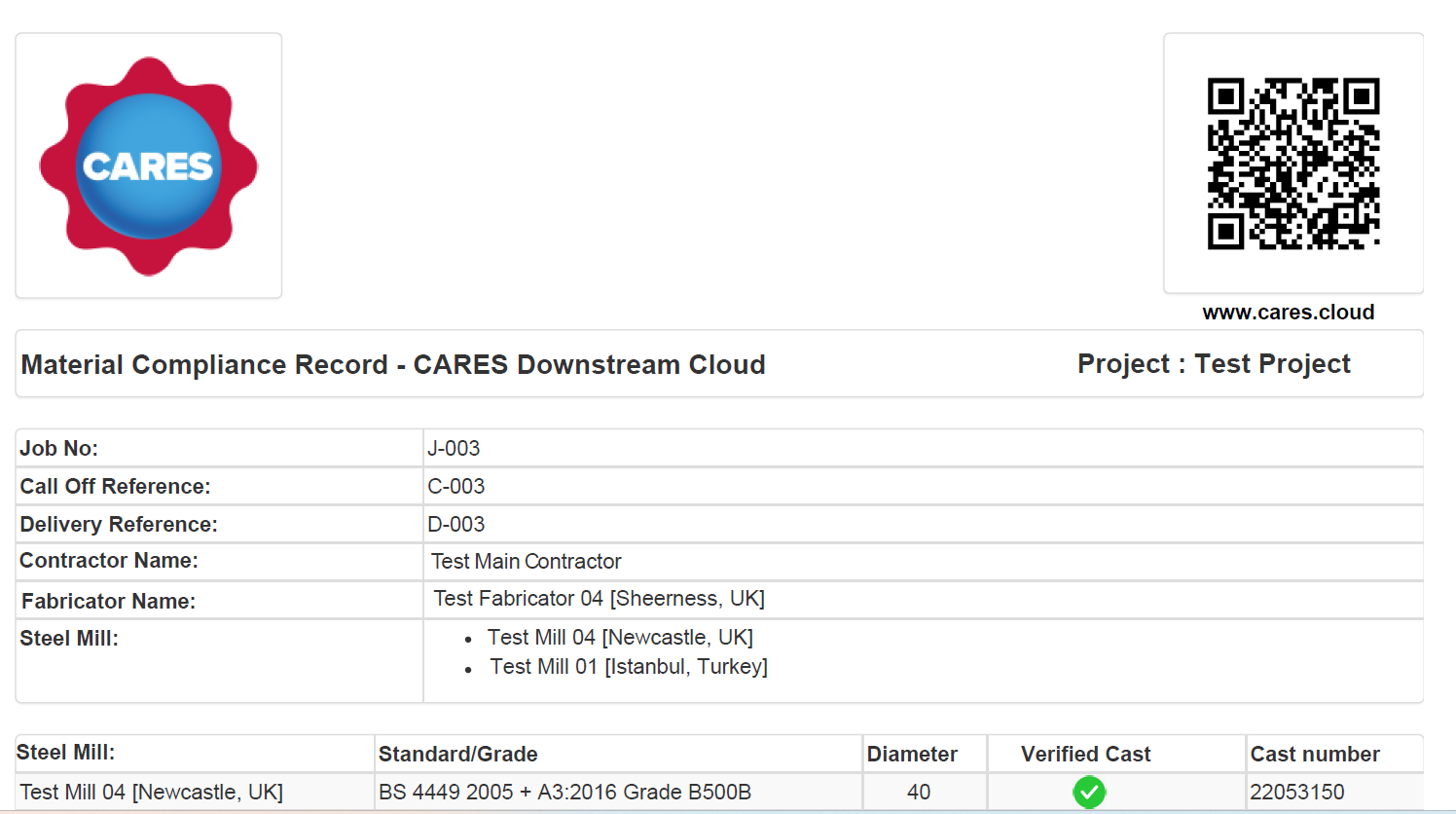

- The data collection process using the CARES Cloud Apps enabled a dedicated project dashboard to record, analyse and summarise the data along the supply chain, in real-time. Summary Material Compliance (MCR) reports were also provided, as per the test example in Figure 2.

- Supply chain transparency delivered via the dashboard, provided a single source of truth which increased confidence in the product’s integrity, production safety record and carbon accountability.

- Carbon savings data could be accurately quantified, based on the actual manufacturer of the reinforcement, the quantities used, production methods and origin of manufacture.

- The scopes of approval of the reinforcement manufacturers and fabricators were readily validated.

Improved productivity

Site productivity was greatly improved through reducing operational time and costs by implementing digital recording of material receipts and demonstrating that paper pro-forma record sheets can be replaced by the system. The trial covered 712 tonnes of reinforcement and delivered an enabled benefit saving of 11 days. Assuming a quantity of 60,000 tonnes this could provide a saving of about 900 days in processing time. Discounted Cash Flow analysis of this time saving shows a positive Net Present Value against the project implementation.

Accurate as-built carbon accounting

The CARES Cloud enabled the use of actual carbon footprint data during the construction phase and overcomes many of the challenges identified by Kaethner and Yang[10], such as a time lag in receiving data, inconsistent formats and an inability to assign available information to a particular batch of incoming materials.

It collated the carbon footprint data for all reinforcement manufacturers in the UK and elsewhere and the tonnage from each manufacturer was reported and analysed via the CARES Cloud dashboard. It should be noted that using the traditional approach the tonnage supplied by each rebar manufacturer is not readily available or routinely provided.

Carbon footprint saving

By providing easily accessible Global Warming Potential (GWP) data, which previously was either unavailable or required considerable effort to source, the CARES Cloud unlocked the ability of the procurement team to make informed decisions and give preference to lower emission steel sources, as well as enabling them to accurately calculate the actual emissions associated with the reinforcing bar. This delivering an enabled benefit (non-cash) saving of £19,000 based on the carbon price used at the time of £50 per tonne. This would create the potential for a (non-cash) saving of about £3.6 million in CO2eq for 60,000 tonnes of rebar based on a carbon price of £50 per tonne of CO2eq and a GWP of 0.760 tCO2eq per tonne of rebar (CARES sector average).

Decarbonisation contribution

The carbon savings and digital data exchange support HS2’s carbon reduction plan and commitments, and this system can contribute towards any company’s corporate commitments to reduce carbon emissions. For example, in line with defined industry pathways such as Co2nstruct Zero[11] and SteelZero[12] which promote the increased procurement of low emission steel.

Improved assurance processes

CARES Cloud provided robust detailed assurance evidence as well as reliable, accurate, easily accessible product information and evidence of assurance for inclusion in project BIM models, enabling seamless connectivity to other systems via APIs. All CARES-approved reinforcement manufacturers, fabricators, and processors were available on the dashboard, including any revisions to their scopes of approval during the project.

CARES Cloud provided data from the source mill to the site, proving chain of custody and EPD information which enabled the accurate reporting of quantities supplied from UK and non-UK manufacturers.

Compliance with Procurement Policy Note PPN04-23

The CARES Cloud provided HS2 the toolset to comply with UK Government’s commitment in supporting UK businesses and industry, decarbonisation and levelling up through their policy note PPN 04-23[13] (Procuring Steel in Government Contracts) by:

Item 9

(b) In-scope organisations are required to collate data and provide an annual steel data return

Item 11

In-scope organisations are required to submit, to the Department for Business and Trade (DBT), the steel origin data as set out in the Inspection Certificate (EN 10204 Type 3.1).

In-scope organisations are required to indicate whether the origin stated is also recorded in the certificate as where the steel was melted and poured.

Mace Dragados JV was able to comply fully with this procurement policy notice with confidence, and integrity by using the CARES Cloud.

Learnings and recommendations

The use of the CARES Cloud provided a highly efficient method to collect quality-assured data for the steel rebar value chain and to use it to meet HS2 goals. The application of the CARES Cloud, the learning and its benefits have also been described in a series of You-Tube videos [13][14][15].

The transparency offered by the system meant that it was possible to state authoritatively and with a high degree of confidence, how the project complied with HS2 requirements and UK Government Policy to re-design procurement specifications and award criteria.

While using the CARES Cloud eliminates manual efforts to collect and verify data and information across the supply chain, future projects using CARES Cloud should consider implementing appropriate commercial models for project teams, subcontractors, and suppliers to use the tool, so that its use is maximised. The system proved to add value and efficiencies, not cost to the programme.

Engaging design engineers, fabricators, contractors, and clients in the use of CARES Cloud at an early stage in the project could improve sharing of information supporting planned and actual upfront ‘embodied carbon’ to be established and plans to reduce them to be implemented.

Conclusion

The CARES Cloud offers a valuable digital solution for tracking both the quantities, quality and characteristics of steel rebar used.

Through the implementation of the CARES Cloud, we have learned invaluable lessons about the need for process optimisation, re-evaluating and streamlining workflows to improve efficiency in rebar tracking and quality assurance. Experience of using the CARES Cloud has also deepened our understanding of the environmental impact of the rebar supply chain, providing insights that guide our sustainability efforts and contribute to a more environmentally conscious construction industry.

The integration of data from the rebar supply chain in real-time into the HS2 project enables evidence-based decision-making and a strategic opportunity to pivot towards local and regional production, a move that promises to significantly bolster the project’s resilience and sustainability.

Moreover, this approach will play a crucial role in fostering employment and ensuring the retention and growth of specialised skills within the local workforce, thereby strengthening the industry’s long-term capabilities. The insights gained from CARES Cloud data will be instrumental in realising these strategic goals, ensuring that HS2’s infrastructure is built on a foundation of safe, responsibly sourced materials, economic prudence, and social responsibility.

Acknowledgements

Andrew Kinsey, Sustainability Operations Director, Mace

Lee Brankley, CEO, CARES

Andrew Woolnough, CEO, Digital Construction Solutions

Dave Knight, Sustainability Advisor, CARES

References

- Grenfell Tower Inquiry. Phase 1 Report.

- BREEAM. BREEAM Infrastructure

- CARES Certification. Sustainable Constructional Steel Certification Scheme

- UK Government. Procurement Policy Note 11/16: Procuring Steel in Major Projects – Revised Guidance

- UK Government. PPN 04/23: Procuring Steel in Government Contracts.

- Mace Group. Mace and Dragados Preferred Bidder to Deliver HS2 Station at Euston

- CARES Certification

- UK Digital Construction

- CARES Certification. Environmental Product Declarations

- Kaethner S, Yang J. Environmental Impacts of Structural Materials – Finding a Rational Approach to Default Values for Software. Institution of Structural Engineers, London; 2011.

- Construction Leadership Council. CO2nstructZero

- The Climate Group. SteelZero

- CARES Cloud Transformation

- UKCARES Cloud APP 2021

- CARES Cloud

Peer review

- Michael JonesHS2 Ltd