Establishing best practice whole-life carbon baselines for Phase One of HS2

Reducing carbon emissions from infrastructure delivery is key to achieving national carbon emission reductions and is fundamental to addressing the global challenge of climate change. There is also a compelling business case for reducing infrastructure carbon emissions. Reducing carbon emissions can reduce costs, unlock innovation and drive better solutions, drive resource efficiency and deliver better-performing infrastructure.

High Speed Two (HS2) Ltd has adopted ambitious targets to reduce carbon emissions from the construction and operation of the programme. Whole-life carbon emission baselines are necessary to determine carbon reduction performance against the targets and are essential in enabling effective carbon management.

Through collaborative working with – and between – supply chain partners, whole-life carbon baselines have been established for HS2 Phase One civil assets and stations; a first for an infrastructure project of the nature and scale of HS2. The baselines, produced in accordance with best practice standards, create a reference level against which whole-life carbon reduction performance can be monitored and reported and identify ‘carbon hotspots’ – sources of carbon emissions with the greatest impact and potential for carbon reduction – on which to focus efforts to reduce emissions.

This paper outlines how whole-life carbon baselines have been established for Phase One civil and stations assets, presents key outputs from the process and identifies key lessons learned relating to accuracy, collaboration, tools and continual improvement, that can be applied to future HS2 carbon baseline activities and other infrastructure projects.

Introduction

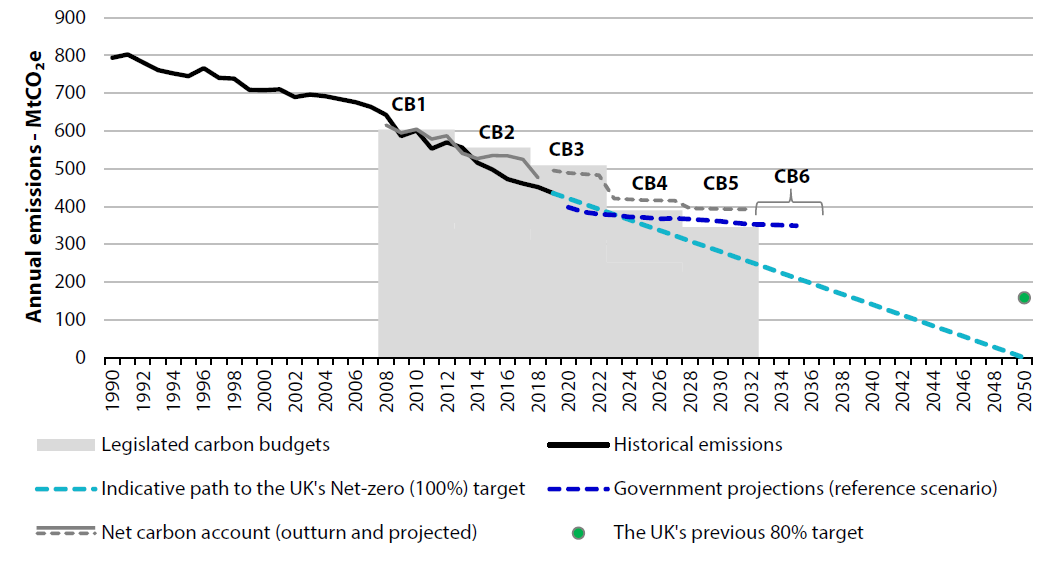

Climate change is a global issue, addressing it is at the forefront of environmental public policy around the world. In June 2019, the United Kingdom (UK) became the first major economy in the world to pass laws to end its contribution to global climate change by 2050[1]. The legislation requires the UK to bring all greenhouse gas (GHG) emissions to net zero by 2050. The target is supported by interim legislated carbon budgets. Figure 1 shows the historic carbon emissions and reduction to date, the five legislated carbon budgets, current Government projections and an indicative path over the next 30 years to achieve net zero carbon emissions. The term ‘carbon’ is used throughout this paper to mean the carbon dioxide equivalent of all greenhouse gas emissions.

Infrastructure is associated with over half of the UK’s total carbon emissions[3]. Around 30% of these emissions are directly attributed to the construction, operation and maintenance of infrastructure assets, such that they can be directly controlled by the infrastructure sector. The other 70% is due to the users of infrastructure, over which the infrastructure sector has influence rather than direct control.

Reducing infrastructure carbon emissions is key to achieving national carbon emission reductions[1] and is fundamental to addressing the global challenge of climate change. Additionally, as recognised in the Infrastructure Carbon Review[3], there is also a compelling business case for reducing infrastructure carbon emissions. Reducing carbon emissions can reduce costs, unlock innovation and drive better solutions, drive resource efficiency and deliver better-performing infrastructure.

The opportunity to reduce carbon emissions has been identified as a potential benefit of a national high-speed rail network for Britain and formed part of the justification for the investment in High Speed Two (HS2)[4]. Inevitably, the construction and operation of the new railway will result in carbon emissions; however the HS2 Environment Policy[5] articulates a commitment to ‘minimise the carbon footprint of HS2 and deliver low carbon long distance journeys supported by low carbon energy’ and the programme has adopted ambitious targets to reduce whole-life carbon emissions associated with the construction and operation of Phase One.

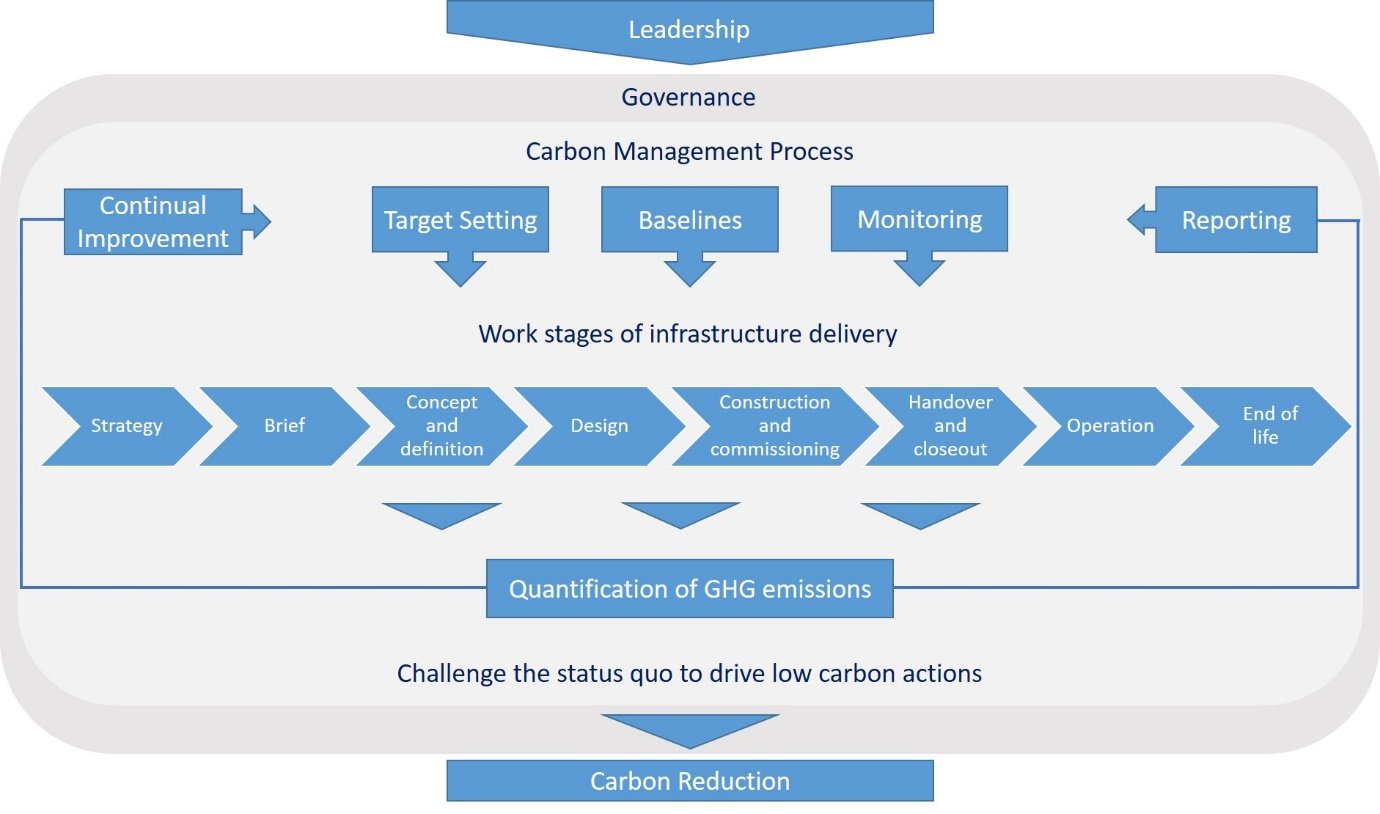

To support the successful delivery of the programmes carbon reduction obligations and objectives, High Speed Two Limited (HS2 Ltd) has developed and implemented a carbon management system aligned to the best practice specification, PAS 2080:2016 – Carbon management in infrastructure[6]. PAS 2080 provides a common framework for all infrastructure sectors and value chain members on how to manage whole-life carbon when delivering infrastructure assets and programmes of work. The PAS promotes reduced carbon, reduced cost infrastructure delivery, more collaborative ways of working and a culture of challenge in the infrastructure value chain through which innovation can be fostered. It includes requirements for all value chain members to demonstrate leadership and to establish effective governance systems for reducing whole-life carbon.

Figure 2 identifies the key components of a PAS 2080 carbon management system. Whole-life carbon baselines are essential in enabling effective carbon management. A carbon baseline reflects a scenario – for a functionally equivalent solution – for what carbon emissions would have been in the absence of planned measures aiming to reduce emissions. The purpose of the baseline is to provide a reference case against which to determine carbon reduction performance. A carbon baseline allows for meaningful application of carbon reduction targets, monitoring of carbon reduction performance and reporting and communication to stakeholders. Carbon baselines are also critical to making carbon reduction performance visible throughout delivery and in informing decision-making to manage whole-life carbon emissions.

This paper outlines how whole-life carbon baselines have been established for Phase One civil and stations assets, presents key outputs from the process and the lessons learned that can be applied to future HS2 carbon baseline activities and other infrastructure projects.

Whole-life carbon

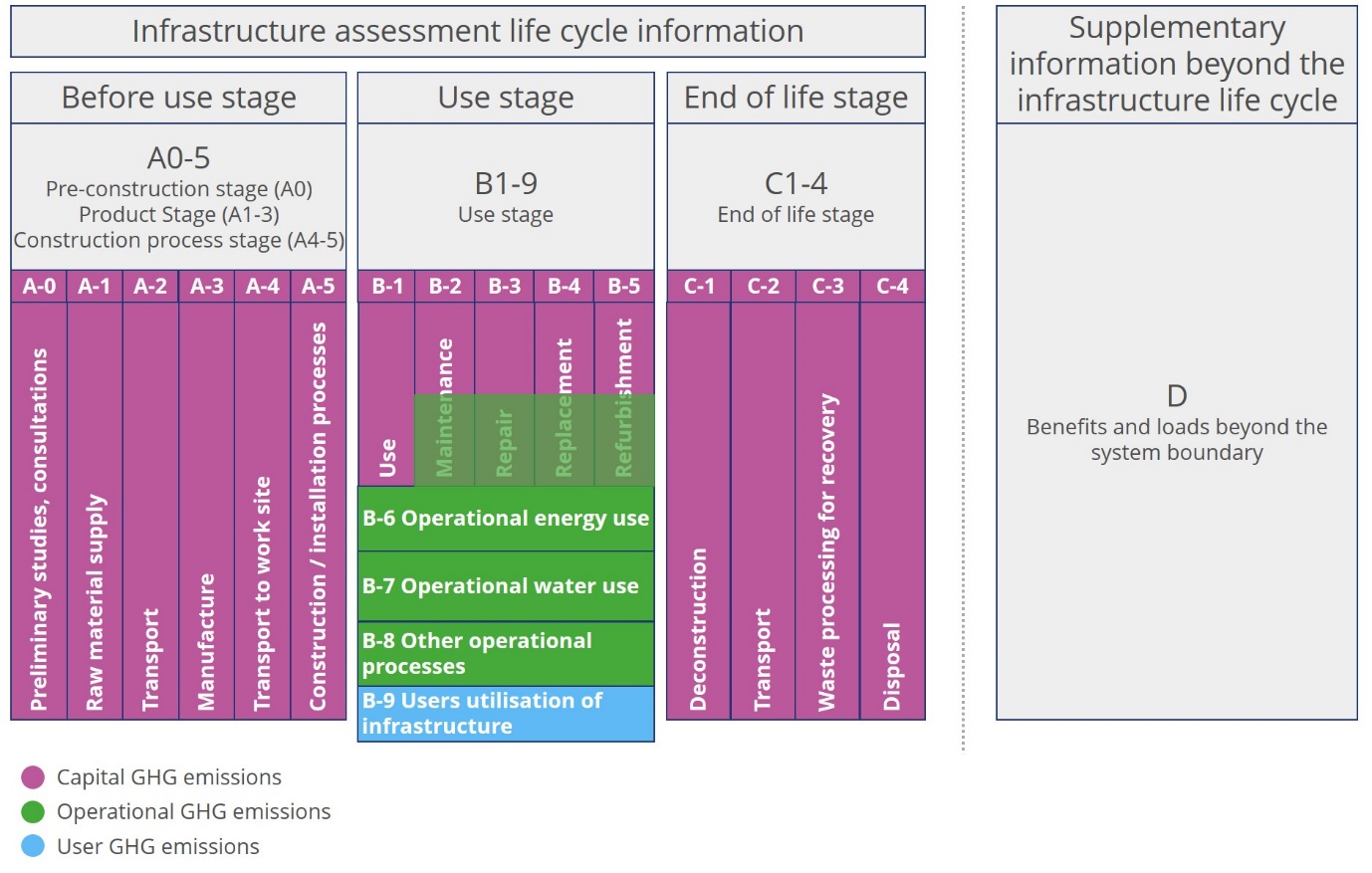

HS2 Ltd’s carbon management approach seeks to define and implement measures that achieve reductions in whole-life carbon emissions. Whole-life carbon is the sum of GHG emissions from all stages of the life cycle of a product or asset and within the specified system boundaries of the product or asset.

This includes:

- Capital carbon: emissions associated with the creation, refurbishment and end of life treatment of an asset.

- Operational carbon: emissions associated with the operation of infrastructure required to enable it to operate and deliver its service.

- User carbon: emissions associated with users’ utilisation of infrastructure and the service it provides during operation.

Figure 3 summarises the framework for the quantification of carbon emissions for an infrastructure asset or programme of work and illustrates the relationship of capital, operational and user carbon with the detailed life cycle modules for information reporting. Table 1 provides a brief description of each life cycle module. Further, more detailed guidance is provided in BS EN 15978:2011[7].

| Life cycle stage | Activities incorporated |

|---|---|

|

Pre-construction stage (module A0) |

Represents preliminary desk-based studies and works such as; strategy and brief development, architecture, design efforts, EIA and cost planning. |

|

Product stage (modules A1-A3) |

Represents raw material extraction, precursor product processing, and final product manufacture, its energy use, and waste management within these processes. |

|

Transport to site (module A4) |

Represents transportation (including intermediate storage and distribution) of products/materials and construction equipment to the construction site from point of production/storage to site. |

|

Construction and installation (module A5) |

Represents construction site works activities including temporary works, ground works, and landscaping; materials storage and any energy or otherwise need to maintain necessary environmental conditions; transport of materials and equipment on site; installation of materials and products into the infrastructure asset; emissions associated with site water demand; waste management activities (transport, processing, final disposal) associated with waste arising from the construction site; production, transportation, ad waste management of materials/products lost during works. |

|

Installed products and materials (module B1) |

Represents the carbon emissions or removals directly from the fabric of products and materials once they‘ve been installed as part of infrastructure and it is in normal use. |

|

Maintenance, repair, replacement and refurbishment (modules B2-B5) |

Represents the works activities and new materials for the maintenance, repair, replacement and refurbishment of the infrastructure during the use stage/operation of infrastructure. |

|

Operational energy (module B6) |

Represents the carbon emissions resulting from the energy used by infrastructure-integrated technical systems to enable it to deliver its service during operation. |

|

Operational water (module B7) |

Represents the carbon emissions resulting from the consumption of water required by infrastructure to enable it to operate and deliver its service. |

|

Other operational processes (module B8) |

Represents other process carbon emissions arising from infrastructure to enable it to operate and deliver its service including management of operational waste. |

|

Users utilisation (module B9) |

Represents the activities associated with user’s utilisation of the infrastructure during the use stage. |

|

Deconstruction (module C1) |

Represents the on-site activities of deconstructing, dismantling and demolishing the infrastructure. |

|

Transport (module C2) |

Represents all carbon emissions due to transport to disposal and/or until the end-of-waste state of waste materials arising. |

|

End of life stage – waste processing (module C3) |

Represents the activities associated with treatment and processing for recovery, reuse and recycling of waste materials arising from infrastructure. |

|

End of life stage – disposal (module C4) |

Represents carbon emissions resulting from final disposal of demolition materials. |

|

Benefits/loads beyond the project boundary Module D |

Includes

|

Establishing whole-life carbon baselines

Whole-life carbon baselines have been established as a product of life cycle assessment (LCA). LCA is a systematic tool that enables the analysis of environmental loads of a system throughout its entire life cycle and the potential impacts of these loads on the environment. Figure 4 summarises the principal quantification steps.

To communicate roles and responsibilities for establishing carbon baselines and to ensure consistent, transparent and robust quantification of carbon baselines, HS2 Ltd developed a technical standard detailing the programme’s life cycle assessment quantification and reporting requirements. The technical standard requires that LCA is conducted by a suitably qualified LCA practitioner and mandates compliance with best-practice standards and guidance, including; PAS 2080[6], BS EN 15978[7], BS EN 15804[8], BS EN ISO 14040[9] and BS EN ISO 14044[10].

In addition, the following general principles were applied in establishing the carbon baselines. The carbon baseline should be:

- based on a scenario representative of a functionally equivalent solution (i.e. the scenario must be consistent with the intended use and the function delivered by the asset/system);

- based on data representative of typical UK construction supply chains and practice current at the time the carbon baseline is established; and,

- aligned with contract scope and delivery arrangements.

The condition to establish a carbon baseline and to do so in compliance with the technical standard was instructed – as a contract requirement – to the supply chain partners responsible for designing the civil assets and stations. Briefings – led by HS2 Ltd subject matter experts – took place upon contract award to ensure common understanding of the programme’s life cycle assessment requirements. This was complemented by collaborative working with – and between – supply chain partners to ensure, where appropriate, consistency of system boundaries, inclusions and exclusions, commonality of key assumptions and LCA tools and consistent application of LCA principles, rules and requirements.

The reference study period for each carbon baseline was 120 years – the programme’s assumed design life – to reflect the greatest ‘minimum design working life’ of the civil assets and stations. The design working life is the period over which a structure or any part of it shall meet its intended purpose and performance requirements with planned maintenance intervention, e.g. replacement of bearings, but without disruption to passenger services or major repair. Sources of activity data for the carbon baselines included best available design information and industry average data – for example sourced from the Royal Institution of Chartered Surveyors (RICS) Professional Statement on whole-life carbon assessment[11]. Data gaps were filled by conservative assumptions using generic data. Any assumptions used to fill data gaps and the limitations they may have on the relevance of the carbon baseline were transparently stated.

For stations, an IMPACT compliant software tool (or equivalent) was mandated – to meet BREEAM requirements. The four station design teams used the same proprietary LCA tool to establish carbon baselines for the stations. For civil assets, an IMPACT-compliant software tool (or equivalent) was recommended, to ensure consistency across the programme. However, other tools were allowed to be used where the programme’s LCA requirements were met. The four joint ventures responsible for the design of the civil assets each used different LCA tools to establish the carbon baselines for the civil assets.

Subject matter experts from HS2 Ltd applied a progressive assurance approach as a means to check compliance with the programme’s LCA requirements and, in particular, to ensure:

Relevance – data and assessment methods relevant to the defined boundary of assessment are selected, documented and used.

Completeness – all life cycle carbon emissions arising within the defined system boundary which provide a material contribution to the management and assessment of carbon emissions are included.

Consistency – consistent methodologies and data sources for assessment are used to allow comparisons.

Accuracy – the quantification of carbon emissions neither overestimates or underestimates actual emissions, as far as can be judged, and uncertainties are reduced as far as reasonably practicable.

Transparency – sufficient information is available on the methodology and data sources used and any relevant assumptions.

Results

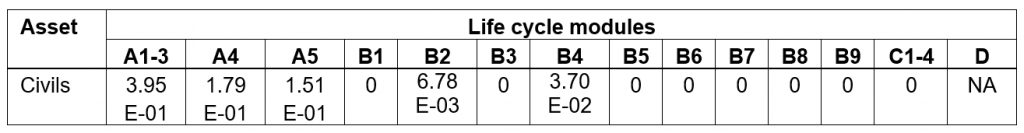

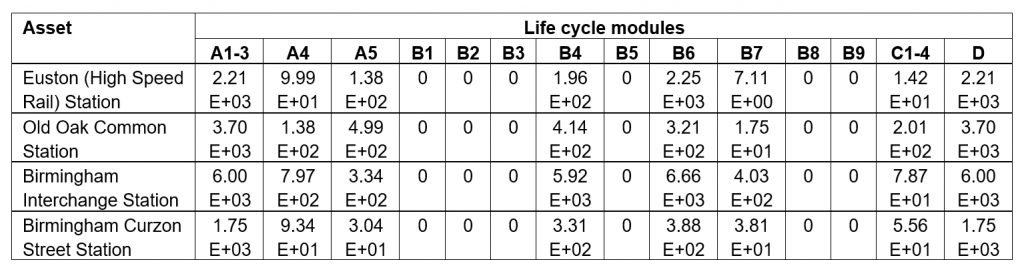

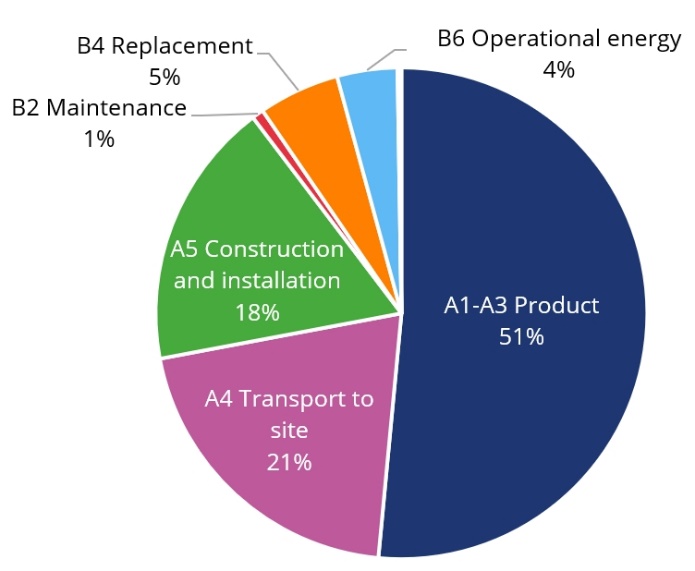

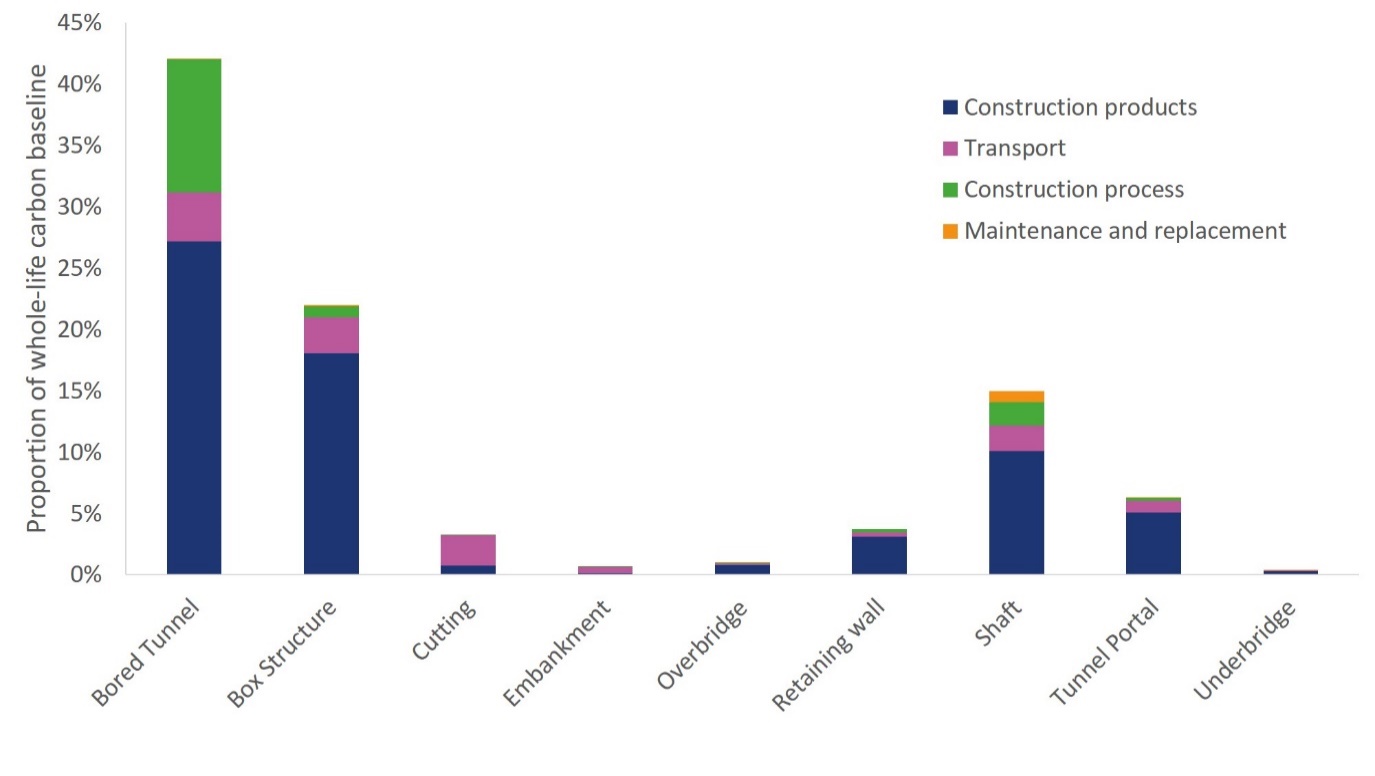

The whole-life carbon baselines have created a reference level against which whole-life carbon reduction performance can be monitored and reported. Table 2 and Table 3 present the carbon baselines for the Phase One civil assets and stations respectively. The carbon baselines have been normalised – using performance metrics linked to their intended function – to enable fair and meaningful comparisons with peer projects.

The carbon baselines have also enabled the identification of programme (see Figure 5), contract and asset (see Figure 6) level ‘carbon hotspots’ (sources of carbon emissions with the greatest impact and potential for carbon reduction) on which to focus efforts to reduce whole-life carbon emissions.

Lessons learned

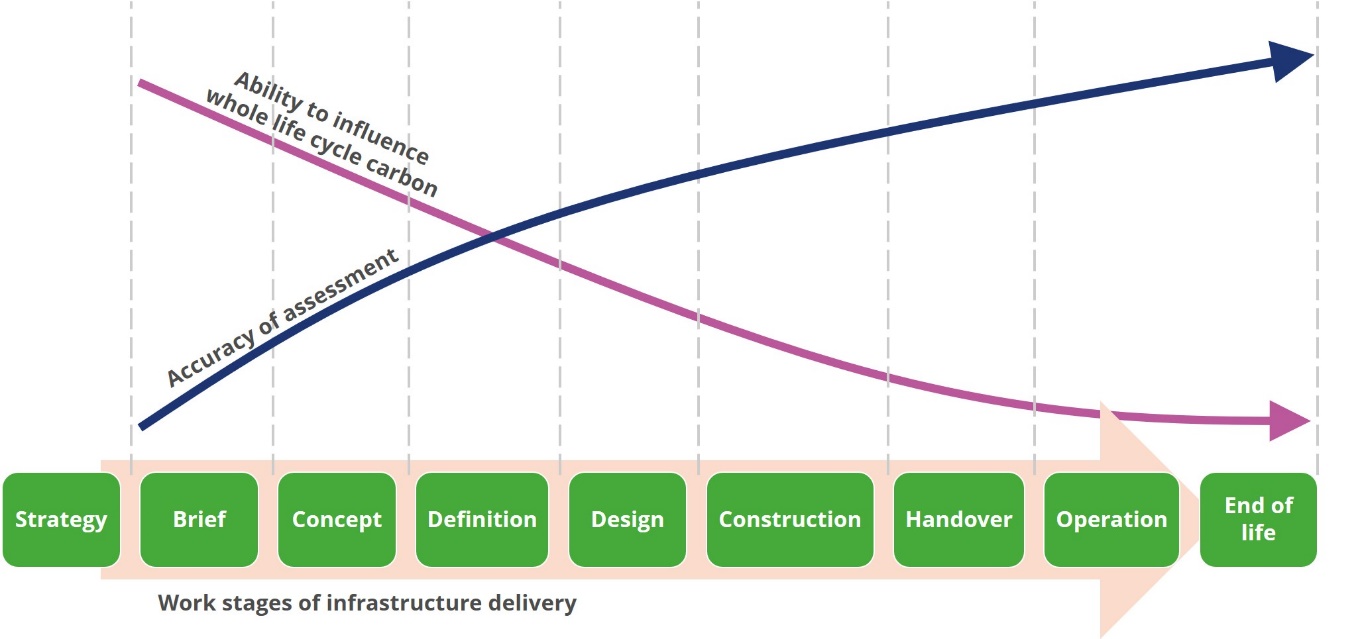

Accuracy

One of the main challenges for establishing whole-life carbon baselines during early design stages is the accuracy and completeness of available activity data; Figure 7, featured in PAS 2080[6], acknowledges and summarises this challenge. As a ‘pop up’ client, HS2 Ltd does not have an inventory of historical ‘as built’ data from which activity data can be derived to establish carbon baselines. As such, early design information has been a key input for the carbon baselines for the Phase One civil assets and stations. HS2 Ltd recognises that there are inherent limitations with this approach and has sought to apply methodologies that assess and reasonably minimise uncertainty and yield accurate, consistent and reproducible results.

However, it should also be recognised that baselines are a means to an end. Be mindful that the pursuit of perfection can detract effort from the ultimate objective – carbon reduction. A balance needs to be achieved to establish appropriately robust baselines, so that carbon reductions cannot be claimed when they are based on outdated or inappropriate baselines, whilst accepting that it’s unlikely that all sources of uncertainty can be eliminated. In such instances the best available data should be chosen and be complemented by evaluation of uncertainty and transparent reporting of the goal, scope, assumptions and limitations of the carbon baseline. It is critical however, that mechanisms are put in place that require the collection of relevant data during infrastructure delivery so improved baselines can be created for future assets and programmes of works.

There are circumstances where it may be necessary to update carbon baselines; for example, where there is a change in contract scope, such as changes to schedule or spatial – ‘red line’ – boundary. A procedure should be defined and documented to manage how and when updates or re-baselining may occur. On the HS2 programme, professional judgement, using industry-recognised LCA cut-off rules to guide decision making, is applied to determine whether the change is likely to have a material impact on the carbon baseline (i.e. materially increase/decrease the carbon baseline). If the change is considered likely to have a material impact on the baseline, the risk is managed via the programme’s early warning notice risk management procedure.

Collaboration

The development and instruction of a technical standard detailing the programme’s LCA quantification and reporting requirements is a key mechanism to ensure consistency and minimise uncertainty. A technical standard – or similar – does support the establishment of robust whole-life carbon baselines; however, it is not sufficient to just have a technical standard. Technical requirements can be interpreted and applied differently and should therefore be complemented by briefing sessions (or similar), collaborative working and an appropriate level of progressive assurance to ensure common understanding and application of LCA requirements. Collaborative working with – and between – supply chain partners has been an essential part of establishing whole-life carbon baselines for Phase One civil assets and stations.

Tools

The value of a common, client assured and/or approved, LCA tool that is designed to meet the programme’s LCA requirements became increasingly apparent whilst establishing the carbon baselines for the civil assets and stations. In the absence of an HS2 LCA tool, the supply chain partners responsible for designing the civil assets and stations were able to select and use any LCA tool – where it could be demonstrated that the tool met the programme’s LCA requirements. A number of proprietary LCA tools suited to buildings were available and familiar to those designing the stations. However, the availability of an LCA tool well suited to civil assets was more limited.

To enable more efficient and effective delivery of future HS2 carbon baseline activities HS2 Ltd has procured an LCA tool. HS2 Ltd subject matter experts have worked closely with the LCA tool provider to develop, enhance and assure functionality aligned with the needs of the programme – for example developing ‘bulk upload’ functionality to minimise data processing burdens. In addition, guidance has been developed and appropriate training made available to facilitate the uptake and implementation of the LCA tool. It is intended that the LCA tool will be used for future HS2 carbon baseline – and broader LCA – activities. It is expected that this will bring benefit both to supply chain partners and HS2 Ltd by facilitating more effective and efficient quantification, reporting and progressive assurance of future whole-life carbon baselines. In addition, through time, the LCA tool will help to build an inventory of data; enabling more rapid development and improving the accuracy of future whole-life carbon baselines.

Continual improvement

It is important to review technical requirements and supporting processes to ensure they are delivering the desired outcomes and are not overly – or unnecessarily – burdensome to particular supply chain partners. To drive continual improvement, feedback should be sought from those involved in establishing and assuring carbon baselines. For future HS2 carbon baseline activities it is intended that whole-life carbon baselines will be established in advance of contract award so that – where appropriate – the carbon baselines can be incorporated into the procurement process or are otherwise available to be provided to supply chain partners upon contract award. The aim is to reduce burden on supply chain partners and to direct effort to higher value-added carbon management and reduction activities, such as design optimisation and development and implementation of low carbon innovation.

Conclusion

Infrastructure is associated with over half of the UK’s total carbon emissions. Reducing infrastructure carbon emissions is therefore key to achieving national carbon emission reductions. HS2 Ltd has adopted ambitious targets to reduce whole-life carbon emissions associated with the construction and operation of Phase One of HS2. Whole-life carbon emission baselines are necessary to determine carbon reduction performance against the targets and are essential in enabling effective carbon management.

Through collaborative working with – and between – supply chain partners, whole-life carbon baselines have been established for Phase One civil assets and stations. The baselines create a reference level against which whole-life carbon reduction performance can be monitored and reported.

Key lessons learned that can be applied to future HS2 carbon baseline activities and other infrastructure projects have been identified and are summarised below:

- there may be limitations when establishing carbon baselines for the first time. In such instances use best available data, transparently report limitations and put in place mechanisms to improve the availability, accuracy and completeness of data so that improved carbon baselines can be established for future assets and programmes of works;

- get the balance right. It’s important that carbon baselines are robust and sufficiently accurate; but be mindful that the pursuit of perfection can detract effort from the ultimate objective – carbon reduction;

- Stakeholder engagement and collaborative working is key to minimising uncertainty;

- technical requirements and standards support the establishment of robust carbon baselines; however requirements can be interpreted and applied differently and should be complemented with appropriate guidance, tools and training;

- a common, client assured and/or approved, LCA tool can support in delivering consistency and minimising uncertainty, bringing benefit to supply chain partners (e.g. by enabling more effective and efficient quantification and reporting) and client (e.g. by enabling more effective and efficient progressive assurance); and,

- continual improvement should be applied with the aim of reducing quantification and reporting burden; enabling more time to be spent on high value-added carbon management and reduction activities, such as design optimisation, supply chain engagement, development and implementation of low carbon innovation.

Acknowledgements

The authors would like to acknowledge the supply chain partners – in particular their subject matter experts and life cycle assessment practitioners – for their hard work and collaborative approach to establishing carbon baselines for the Phase One civil assets and stations.

References

[1] Her Majesty’s Government (2019) The Climate Change Act 2008 (2050 Target Amendment) Order 2019 (online).

[2] Committee on Climate Change (2020) Reducing UK emissions: 2020 Progress Report to Parliament.

[3] HM Treasury (2013) Infrastructure Carbon Review.

[4] DfT (Department for Transport) (2012) High Speed Rail: Investing in Britain’s Future – Decisions and Next Steps. High speed rail: Investing in Britain’s future – decisions and next steps – GOV.UK (www.gov.uk)

[5] HS2 Ltd (High Speed Two Limited) (2017) Environmental Policy.

[6] BSI (2016) PAS 2080:2016: Carbon management in infrastructure. BSI, London, UK.

[7] BSI (2011) BS EN 15978:2011: Sustainability of construction works – assessment of environmental performance of buildings – calculation method. BSI, London, UK.

[8] BSI (2012) BS EN ISO 15804: 2012 Sustainability of construction works. Environmental product declarations. Core rules for the product category of construction products. BSI, London, UK.

[9] BSI (2006) BS EN ISO 14040:2006 Environmental management — Life cycle assessment — Principles and framework. BSI, London, UK.

[10] BSI (2006) BS EN ISO 14044: 2006 Environmental management — Life cycle assessment — Requirements and guidelines. BSI, London, UK.

[11] Royal Institute of Chartered Surveyors (RICS) (2017) Whole-life carbon assessment for the built environment.

Peer review

- Mike de SilvaHS2 Senior Project Manager Phase 2B