HS2 Interchange Station: An exemplar project for integrating safe by design principles

HS2 has set strategic goals in health and safety to create a railway designed, built and operated to world class standards creating a legacy of new and better standards in health and safety[1]. This paper details how the design of HS2 Interchange Station is a prime example of how Safe by Design principles[2] can be considered throughout all stages of a project.

Designing for simpler, easier to use and safer systems is not just a benefit in health and safety terms but can also create long term financial benefits through reduced construction and maintenance costs, by reducing the impact of incidents and accidents during the asset lifecycle.

By adopting modern technology and encouraging close collaboration between the design team, client, contractors, operators and other external stakeholders, the HS2 Interchange Station design has been developed with safety at the heart of the station.

This has included:

• Relocating the station building from over the railway to adjacent to the tracks.

• Reducing the quantum of elevated walkways over and along the platforms.

• Optimising the site cut and fill balance to minimise the need for import/export of fill material.

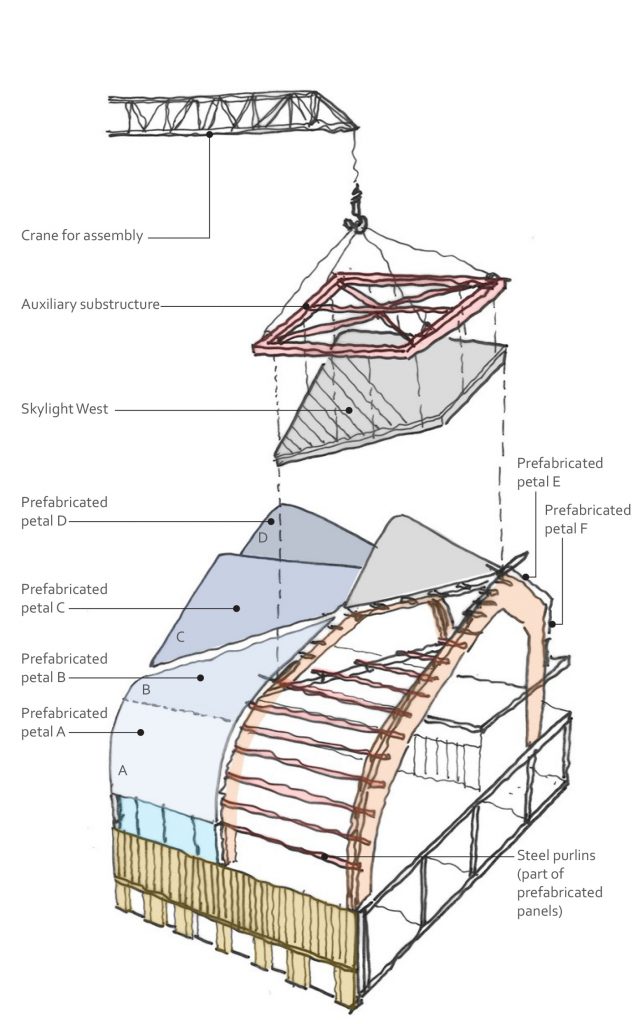

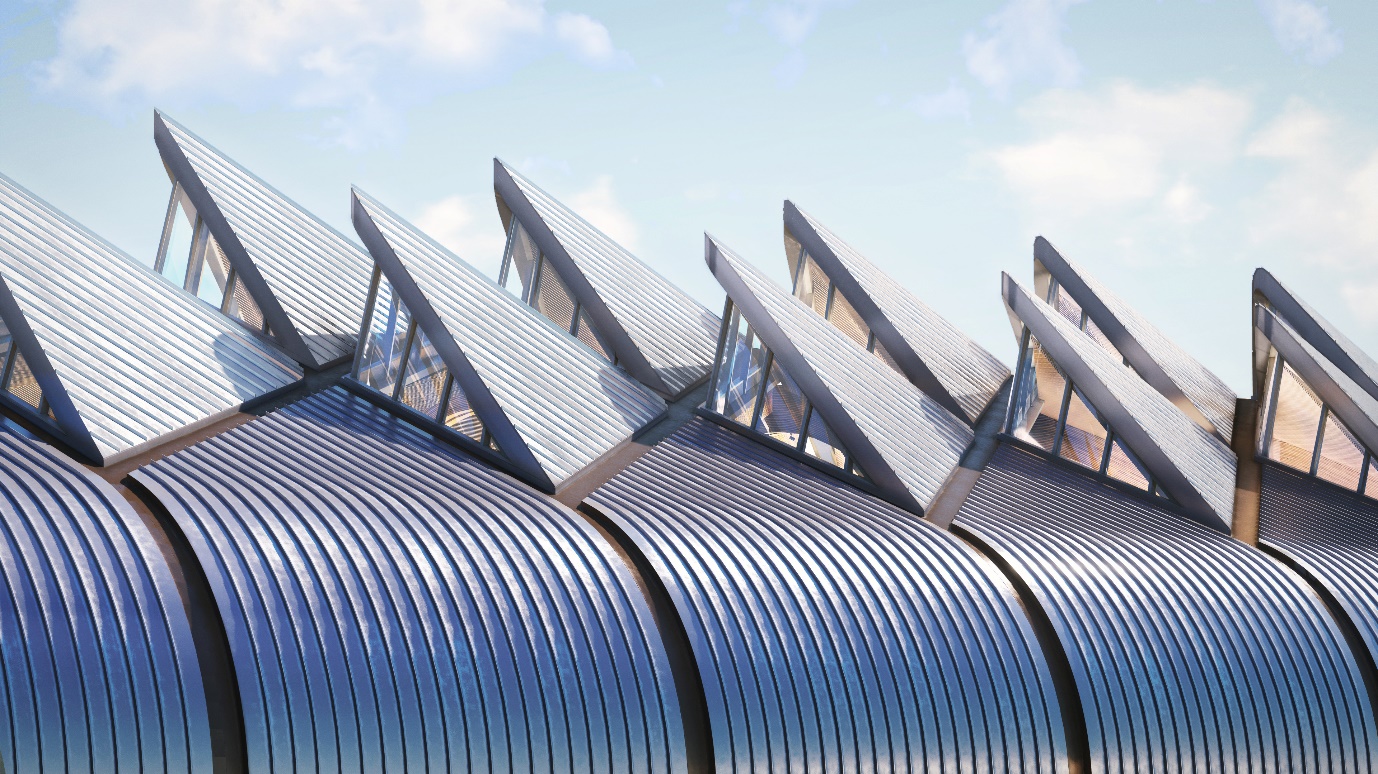

• Modular roof design to maximise pre-fabrication and minimise working at height.

• Providing access corridors for building maintenance which do not clash with the high-speed rail.

These key decisions and many more throughout the design have greatly reduced the health and safety risks users may encounter in the future.

Introduction

HS2 has set strategic goals in health and safety to create a railway designed, built and operated to world class standards creating a legacy of new and better standards in health and safety[1]. A high bar has been set for quality and performance that will deliver benefits beyond the physical limits of the railway and help drive innovation in the wider construction industry. For both HS2 and Arup (Interchange Station’s Design Service Contractor (SDSC)), safety was the foundation of the design philosophy in resolving the complex challenge of placing a significant piece of new infrastructure into its context.

This philosophy, described in this paper, was to work as a fully integrated team applying Safe by Design principles[2], where all aspects of the design, whether to do with passenger experience and inclusivity, technical performance or construction were considered together.

The design team adopted four guiding principles which were embedded into day to day design activity ensuring safety was of central concern.

- To actively seek design solutions that removed or reduced the scope of work first, whilst still satisfying both HS2’s Design Vision[3] and technical standards. This, as described later, included the careful location of the station to optimise the cut and fill balance removing the need for deliveries to the site leading to improved safety. Similarly, the access down to platform was configured to minimise risk by removing the need to build high level lateral circulation concourses over the platforms.

- To actively seek design solutions which help remove complexity and risk from other elements of construction. For example, the use of glulam structure allowed lighter foundations to be used for the main station concourse building.

- Any elements that required access for either installation, maintenance or replacement, as far as practical were relocated to reduce risk. This included, through careful design, placing luminaires lighting the concourse roof at safer heights.

- The design team embraced DfMA (Design for Manufacture and Assembly) at every opportunity. The distinctive ‘leaf’ roof form of the concourse was derived from breaking the roof enclosure into modular units that could be readily manufactured offsite.

Using these principles ensured the design team were able to deliver a design that achieves the highest standard of safety.

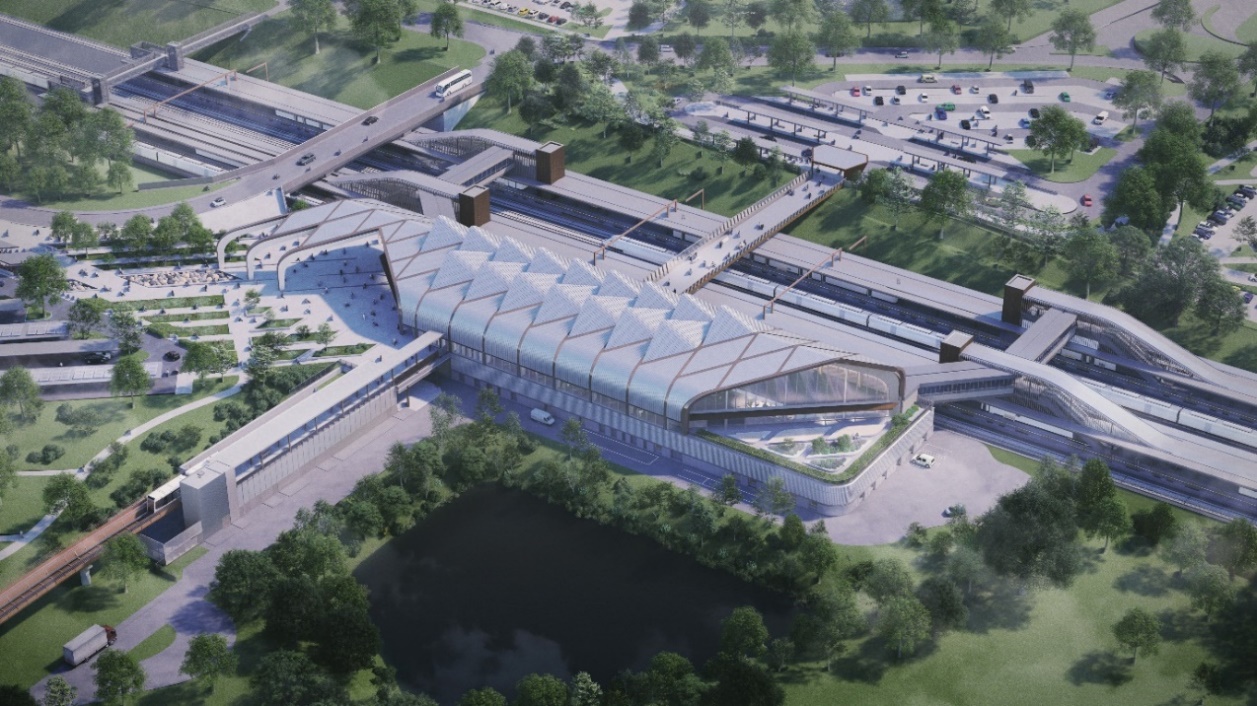

Interchange Station

Interchange Station is located at the heart of the HS2 network, serving the West Midlands, Birmingham Airport and the NEC, and with seamless links to the UK motorway system. The station sits within a green triangle formed by the M42, A45 and A452 to the east of the NEC, known as ‘The Triangle’ site. The station is connected to the NEC, Birmingham International Railway Station and Birmingham Airport by an Automated People Mover.

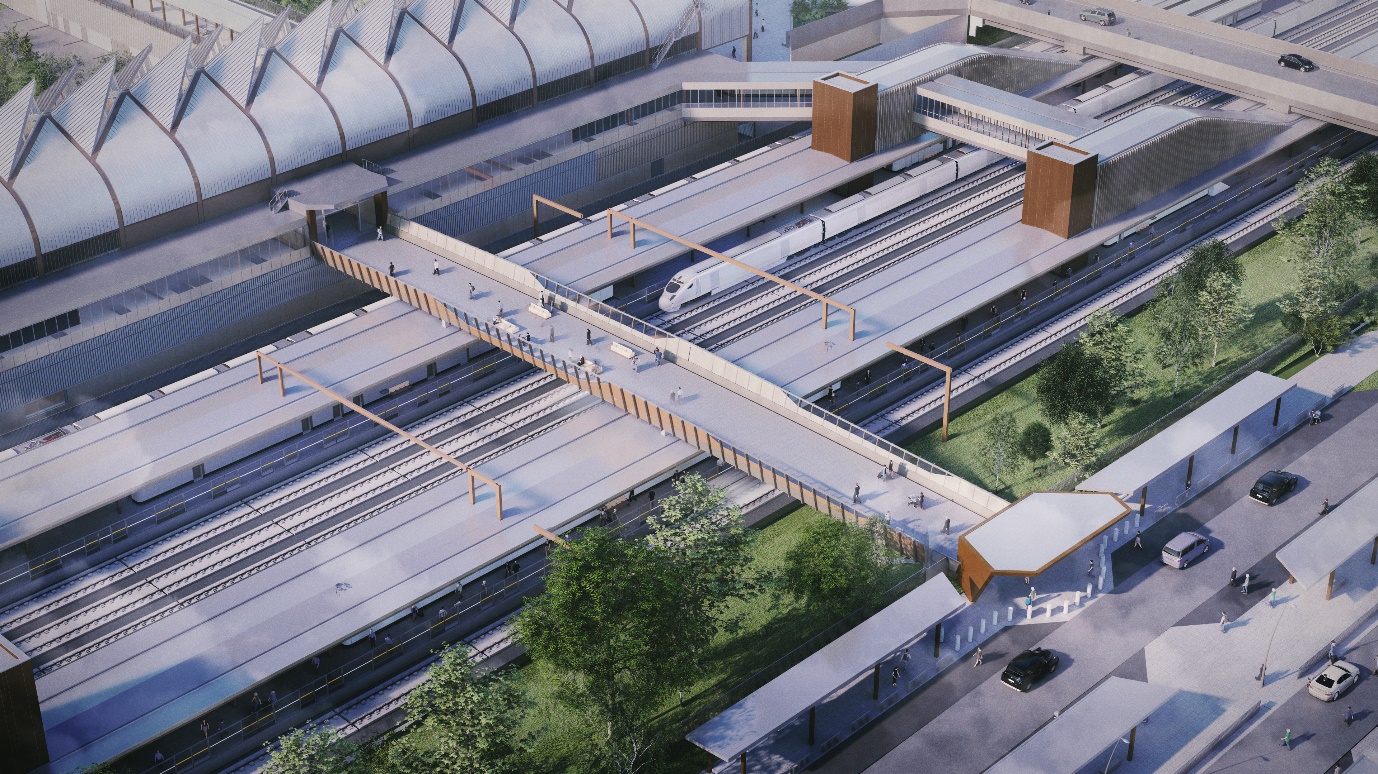

Interchange Station has two 415m long island platforms, with six tracks, two in the centre for the through traffic and four serving the double-face platforms for the stopping trains. It has been designed to serve five 400m long high-speed trains per hour, in each direction.

The main station concourse sits to the west of the platforms, opening to public plaza to the north west (Figure 1 above) and linked to the east of the trace by a pedestrian bridge (Figure 12). The design includes provision for car parking, taxi ranks, Drop&Go and short stay parking, bus stops and cycle storage. Figure 2 shows a bird’s eye view of the station from the west.

HS2 safety policy

HS2 will be a high-speed rail network with demonstrable levels of safety. HS2’s primary aim is to identify and design out safety risks to prevent incidents occurring. If a safety risk cannot be eradicated, it will be mitigated so far as is reasonably practicable.

The concept of health and safety by design aims to eliminate or control health and safety risks by considering potential risks early on, and deal with those risks at the design stage. Designing for simpler, easier to use and safer systems is not just a benefit in health and safety terms but can also give long term financial benefits through reduced construction and maintenance costs and reducing the impact of incidents and accidents in lost time and compensation costs.

By adopting modern technology and encouraging close collaboration between the design team, client, contractors, operators and other external stakeholders, the design has been developed with safety at the heart of the station. During the design process health and safety has been considered for every stage of the station’s life cycle. This includes construction, operation, maintenance and deconstruction.

Design process

The whole design team has been committed to designing with safety as a fundamental aspect of the project. Safety in construction and in operation has been foremost in all decision-making. Planned to endure, safely, for a century or more, Interchange Station will be used by thousands of passengers every day, supported by hundreds of staff, all making use of a substantial multi-modal transportation interchange.

All the design decisions have, therefore, actively considered safety. The Arup design team is multi-disciplinary and has worked in the same shared space with HS2, supported by input from Costain for construction-related solutions. Working together in a multi-disciplinary team, the station design has been developed to implement Construction (Design and Management) (CDM) Regulations, to eliminate, so far as is reasonably practicable, foreseeable risks to the health or safety of any person during construction, maintenance and use. Common Safety Method (CSM) on Risk Evaluation and Assessment was used to assess the safety of the operational railway. This assessed the hazards, risks and associated safety measures and the resulting safety requirements for passengers, the workforce and the public. Bringing together these two complimentary inputs (CDM and CSM) to the architectural and engineering designs have ensured that all aspects of the work have been suitably scrutinised and influenced.

Rigorous design management processes were established and followed throughout the concept and scheme design – the stage in a project when decisions become embedded. These included agenda items for CDM and CSM in every design meeting, design review, optioneering SIFT and workshop. Safety aspects were recorded and actioned so that impacts were eliminated or minimised. To maximise the safety for passengers and staff, human factors, ergonomics and logistics specialists were used to supplement the safety expertise and design team.

Many aspects of the project required interfacing to be documented, together with a clear statement and allocation of safety risk. Collaboration throughout with LMJV – the Enabling Works Contractor (EWC), BBV IPT – the Main Works Civils Contractor (MWCC) and Rail Systems Contract (RSC) ensured understanding of their design solutions and how the interfaces could be safely and effectively managed. Where the project touched neighbours and stakeholders, knowledge was shared at planned sessions – again with a view to optimising safety in use or during initial construction.

Due to the extent of external works in the scheme a particular focus has been on designing suitable solutions for diverted existing and new incoming / outgoing utilities. The solution achieved not only best suits construction of the HS2 works but takes account of potential forthcoming development around Interchange.

Safety has also led to clear decisions around scope and packaging of the works, so that utilities, earthworks, substructures, access and safe preparation for incoming contractors are coordinated and sequenced to minimise potential hazards.

The use of Building Information Management (BIM) throughout the design assisted in many areas. Passenger circulation, staff movements and logistics have all been mapped. Routes to and from the station for travellers, arriving or leaving the station by car, public transport, cycle or automated people mover have all been optimised and secure wayfinding established, concentrating on accessibility for all users. Emergency escape and access for the rescue services have also been key design drivers. The site and the station are designed to be simple to maintain and for complex areas, such as the modular facetted roof. Planned methods have been written into the scheme design solutions and clearly illustrated within the BIM model.

Throughout the concept and scheme designs, HS2’s assurance process has embedded safe-thinking into the design. Whilst this has never been the sole design driver, the combination of skilled expertise from SDSC design team, working closely with HS2 Ltd’s subject-matter-experts, has captured safe-by-design principles.

Assurance evidence has been provided at each project stage and has been rigorously tested by the team. For example, because Interchange Station is land-locked within other contracts there are several interfaces to be addressed. At each interface we have made sure that CDM aspects are correctly allocated and recorded. For the station itself, the CDM and Rail Safety risks are recorded in the appropriate registers and special areas are addressed, for instance the Façade Access and Maintenance Report was subject to several rounds of rigorous checking jointly with HS2 Ltd.

Whenever value management has been untaken, or options have been considered, the safety in construction and in-use have been discussed and scored. The SIFT reports record this and (as noted elsewhere) key decisions were made – such as the off-trace station location – partly for safety reasons. These decisions have been shared with the design panel, who were also able to bring their expertise – of the wider industry in addition to their broader HS2 role – particularly to the project in-use. Vehicle, pedestrian, persons with reduced mobility (PRM), rail and emergency scenarios have all been evaluated in this context.

Site wide considerations

Interchange Station sits within what is commonly referred to as the Triangle Site – hemmed in by the M42, A446 and A45 (shown in Figure 3 below). Safety has been considered not just in the station building itself, but the entire external works which interface with a number of work packages across the Triangle Site.

One of the key moves to ensure the station’s safe construction and future maintenance was to move the main station building off-trace (to the side of the tracks). This has reduced the risk of working near the high-risk areas of the railway systems. It also reduces the number of large, heavy structural members that span over the trace.

The wider site has been redesigned since the hybrid Bill design to reduce the use of retaining walls. Careful manipulation of levels has ensured that no retaining structures are required within the wider landscape. Embankments with planting are proposed instead. This has reduced the risk of working from height and heavy lifting during the construction stage as there is a reduced risk of formwork collapse or collapse of reinforcement cages prior to concreting causing serious injury or death to site operatives.

The Park Farm retaining wall has been eliminated altogether by adopting a landscaped embankment instead. The hybrid Bill design required a vertical retaining wall up to 6.0m in height immediately adjacent to Park Farm to allow for the construction of the Park Farm Roundabout at the low-level highway access from the A452. Concept design proposed a contiguous bored pile wall as the preferred form of construction. Design development of the access road by EWC meant that this wall would have been approaching 7.5m at its highest point. Recognising the implications of constructing such a wall in this location, the SDSC design team reviewed the location and geometry of the roundabout. This review allowed the roundabout to be reduced in diameter and moved south; this shift meant that the retaining wall could be replaced by a graded slope with consequent health and safety benefits during construction and operation.

The cut and fill balance across the site has been optimised, minimising the need to import or export heavy fill material and associated highway traffic movements. The station building itself has been positioned to take advantage of the sloping terrain and has been designed with entrances on both the upper and lower levels which also optimises the cut and fill balance.

Another area where risk has been mitigated is the rerouting and burying of HV cables that currently cross the site. The programme has been re-planned so that the 132kVa lines are moved prior to the station and main works to prevent any clash of works in close proximity. The design reroutes the cables away from any fixed structure and they are buried with a warning strip below the excavation level of the planned external works. The route has been chosen to allow for safe future development of the surrounding site. Temporary steel fences will be installed along each side of the buried route to reduce any chance of striking them while working nearby.

Across the Triangle Site, a series of sustainable drainage systems is proposed. This has reduced the number of large pieces of infrastructure across the site and has highlighted the need to maintain tanks (working in confined spaces).

Interfaces with the wider context have also been considered from a health and safety perspective. Interface Control Documents (ICDs) set out how these will be managed, to reduce the risks associated with each package of work. ICDs outline the responsibility/ownership for the delivery of key elements of the works for Interchange Station, between the SDSC design, main works civils, enabling works and railway systems. Throughout the design process, all parties have shared work in progress design model files to coordinate the various work packages.

Station building considerations

This section will describe how Safe by Design principles have driven the design of the station building and platforms, it will then describe the considerations to construction safety that have been embedded within the scheme design.

The roof of the main station concourse is one of the most visible and important architectural elements of Interchange Station due to its location, size and function. The station roof is the signature feature and the reference which drives other elements of design.

The structures have been designed with a level of inherent structural integrity, to ensure that should they be subjected to accidental or malicious events generating exceptional loads, they will not suffer collapse to an extent disproportionate to the original cause. The glulam primary roof structure has been rigorously tested to ensure it meets fire and security requirements and will not be adversely affected by relative humidity.

The design has been developed with security in mind. The design basis threats have been determined through a Threat and Vulnerability Risk Assessment and the structural systems designed accordingly. A full buildability review has been undertaken in collaboration with the Construction Planning team to understand the risks associated with construction and these have been mitigated and communicated accordingly via the central CDM risk register

The Safe by Design approach is exemplified in the platform and bridge design. The platforms are the interface between the customer space and the high-speed rail system and consequently are exposed to severe hazards, such as high-speed trains and overhead electrification. The bridges span above this dangerous zone and are exposed to many of the same hazards as well as requiring further consideration to the safe use and maintenance of bridges and the security of the rail system. Additionally, the customer space is an active space that has been designed to enable efficient and safe transit for all users.

The interface between the station and rail system has been managed through proactive Interface Control mechanisms. From this, clear exclusion zones have been established so that offsets can be maintained between all platform assets and the platform edge and the supports for overhead contact system seamlessly integrated. This approach considers the whole-life impact, with a clean handover between Station Contractor and Rail Systems with agreed interfaces making the platforms safe for ongoing access and maintenance.

The station structures have been designed to allow for a suitable level of robustness to resist the impact from a derailed train within the station length – primarily using the platforms as impact protection to the columns located within them.

The platform islands are fully covered to protect customers from adverse weather. Clear, uninterrupted platform zones are provided along the length of the platform islands, with a central zone for circulation and structure. The platform design prioritises the platform zone. The generous width allows for safe movement and gives clear lines of sight along the platform. This in turn, facilitates intuitive wayshowing, effective platform clearance times and evacuation, inclusive of all passengers. Platform screen doors add to the safety of the platform. In addition to protection from falling, the platform edge doors contribute towards the health and welfare of the staff on the platforms, providing a barrier to noise from the trains to create safe working conditions.

Interchange has been designed to utilise safe manufacturing techniques wherever practicable. The strategy is to maximise offsite fabrication and minimise on-site operations, therefore reducing exposure to hazards and safety risks, improving quality and consistency of the delivered product and reducing the time for on-site construction. Not only does this approach reduce risks, it will also benefit the safe operation, maintenance and deconstruction of the station, improve quality control, help to reduce costs and help deliver sustainability. This is a large part of why Interchange Station is the first station in the world to be awarded BREEAM Outstanding. This puts it in the top 1% of new buildings in the UK for eco-friendly credentials.

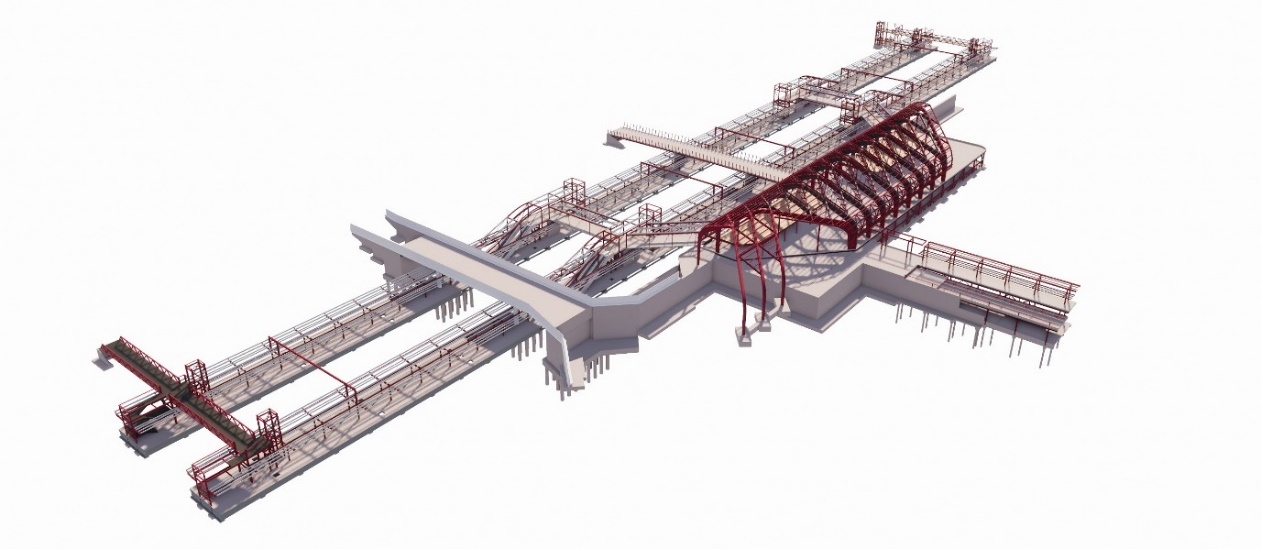

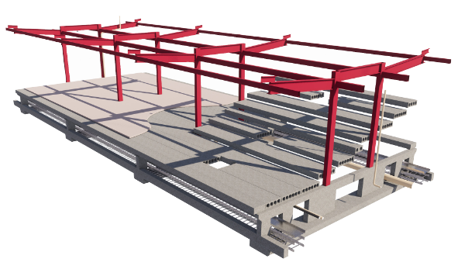

The aim is to produce a scheme primarily by a process of assembly, rather than construction. To this end, where possible, the structural work above foundation level will involve pre-casting and pre-fabrication of components offsite, which are delivered to site as required for installation. This has led to modular, repeatable forms throughout, broken down into standard components which can be economically manufactured, preassembled and safely and efficiently constructed on site. (See Figure 4).

This approach has the benefits of:

- Optimising the design.

- Increasing the quality of construction and finish – especially important with exposed structural finishes.

- Allowing the supply chain to respond with economies of scale in both production and construction.

- Allowing safe, repeatable work sequences to be adopted with reduced time on site.

- Increasing the efficiency of installation and logistic movements.

- Reducing site-based staff and activities.

There has been an increased emphasis to utilise offsite manufacturing techniques wherever possible. This ensures increased efficiency of installation and logistic movements; a reduction of site-based staff, working in a relatively high-risk industry. All these factors lead to a reduction in the hazards to those constructing the station, as well as other site staff. It enables safer, easier and quicker construction with greater quality control assembly on site. Principles of Design for Manufacture and Assembly (DfMA) have been applied to the structural frame, envelope and design elements for the station and platforms. The reduction of time spent working onsite means more work is completed in a safer factory setting, and many hazards of a building site can be avoided.

A lightweight steel and glulam frame structure has been designed with repeated standard structural sized elements and connections on a 9x9m grid. This has meant the majority of the station is designed to sit on pad foundations rather than piles, which are more hazardous to construct.

One of the most challenging areas of construction is the platforms. The two 415m long island platforms have been designed as a series of identical prefabricated elements which can be craned into position on site. The elements have been designed as fully clad soffits and roofs with the MEP containment runs installed within the platform canopy roof cassettes. (See Figure 6)

The MEP containment that runs throughout the station has been designed as prefabricated elements to be quickly fixed together on site. The cladding panels have also been designed as prefabricated elements.

Operational considerations

The SDSC design team worked closely with HS2 Ltd’s Operations Team and Human Factors Team to design the building that ensures the safety, security and wellbeing of the future users. ‘Users’ in this context means maintainers, operators, passengers, staff, support staff, retail staff, British Transport Police or general staff. Where possible, their requirements have been implemented into the design, and risks have been identified, designed out or mitigated.

The back-of-house design is driven by a user-centred approach. The design team has worked with its HS2 Ltd subject matter experts and specialist consultants to understand the operational processes and identified different user groups and their activities. By testing the design against these user groups and their needs, the design team was able to configure space so that station users are never exposed to areas of higher risk to perform their roles. This takes into account the safe movement of vehicles, equipment and goods. Taking full advantage of the existing landscape so that the concourse and HS2 customers are isolated from the back-of-house operations and logistics of the station.

The majority of back-of-house areas are housed in the podium beneath the concourse level. This allows the public unobstructed views out to the landscape on the south west and towards the high-speed lines to the east. The back-of-house facilities are secure and largely hidden from public view. There is a separate back-of-house entrance located at the lower level of the building, accessed via a secure service road. All retain units and can be serviced from the back-of-house areas. This enables the public realm at concourse level to remain fully activated and free from delivery and waste removal vehicles, whilst allowing the station to operate efficiently with opportunity for 24/7 servicing in a secure location.

See figure 7.

The station has been arranged around the topography of the landscape with interchange with buses, cycle parking, taxis, Drop&Go facilities and the People Mover located as close as possible to the station forecourt, with surface car parks located immediately beyond. See figure 8. All points of arrival or departure are step free. The main entrances to the station are marked by public plazas located on the west and east sides of the station. A separate pedestrian bridge links the station to the East Plaza, separate from the main vehicular bridge to the north.

These entrances allow for step free approaches from both sides of the station, optimising the routes from all intermodal connections and reducing the risks of crossing vehicular traffic. The car parks have been designed with segregated paths through them for pedestrians to walk away from traffic.

Passenger and staff journeys have been considered in detail during design to ensure optimum layout and room adjacencies. ‘Day in the Life of’ workshops have been undertaken with future user groups to establish key routes and considerations for those using the station in the future. Hazard Identification Workshops have been undertaken for each area of the station to discuss possible hazards and how they may be mitigated or designed out.

The station concourse has been designed to give panoramic views of the Hollywell Brook Valley and station pond to the south west, to provide amenity and increase the wellbeing of those using the station. There is also a landscaped terrace to the south of the station, providing a space for both the staff and public to enjoy. See figure 9.

Interchange has been designed with the wellbeing of its customers and workforce is mind. The staff have excellent access to welfare facilities and outdoor space. This is important to help establish a culture of safety, pride of place and bring about a better sense of wellbeing. In so doing, it is hoped the design will help reduce stress, anxiety and fatigue which are significant causes of harm in the workplace.

The platforms are located beneath the concourse level, accessed via lifts and escalators at two points along the platform. The platforms themselves are designed to allow step-free boarding and alighting of the trains, with no need for ramps or assistance from staff. The entire platform perimeter is also enclosed with platform edge doors. This reduces the risk of trip hazards or people falling onto the tracks. See figure 10.

Maintenance considerations

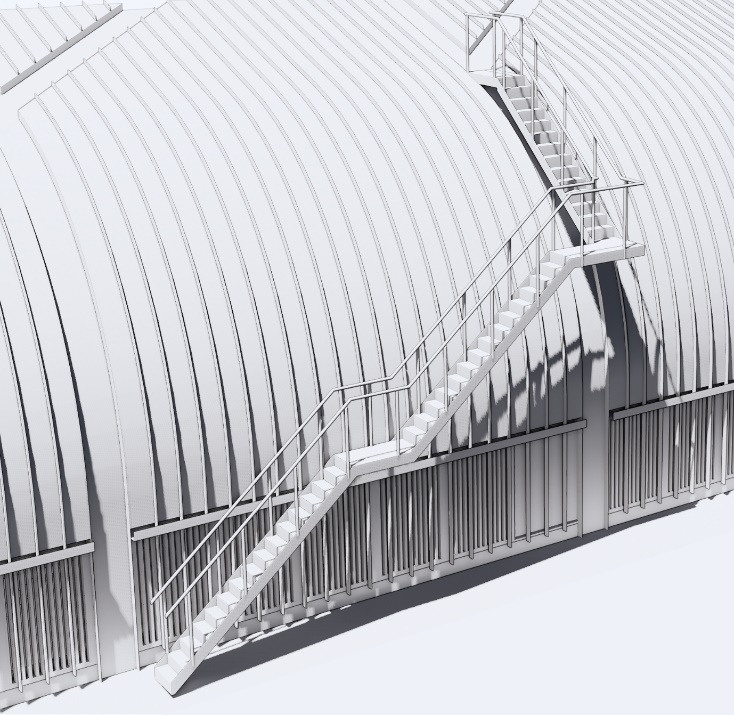

Access and maintenance to the buildings and its assets is an important consideration. Access is required to maintain the visual aesthetics as well as to undertake necessary planned and reactive maintenance to ensure continued operation to prolong life. Safety of operatives undertaking the works and work site protection from others is a key consideration for any access and maintenance strategy. Incorporating this in the early stages of the design process removes the need for large, unsightly roof mounted equipment as this can be incorporated into the form of the building.

Where possible, the station has designed out the need for working at height. All plant equipment has been positioned at ground level, which allows it to be easily installed, maintained and replaced in the future. There is no machinery or air handling units at roof level, which reduces the need to work from height on the roof.

Areas in close proximity to the overhead HV cables have been designed to require minimal maintenance. Structures such as the bridges which cross the tracks have been designed in weathering steel, which has a high level of corrosion resistance (figure 12). This means that the maintenance frequency is reduced as the material is subjected to less damage. Only periodic cleaning and inspection is required. This quality makes weathering steel an ideal choice for structures where future maintenance will be dangerous and difficult, and disruption needs to be kept to a minimum. The reduction of maintenance help to improve safety as the risks associated with it are minimised.

The roof has been designed to incorporate safe access for those inspecting it in the future. There are two main points of access from the station concourse level at both the north and south ends. These are both from secure back-of-house corridors, away from public areas. Bespoke external access stairs have been designed to fit neatly within the geometry of the roof, rather than ladders. These lead up to the concourse mezzanine level though mechanically operated access hatches. This ensures opening and closing can be achieved single-handedly. These access hatches are also designed with handrails (or gates) on all open sides. Handrails and rest areas are also provided (see Figure 13). There are also water points provided at the top of the stairs so that water is not required to be carried up the stairs in buckets.

Once on the roof itself, non-slip walkways and cable line restraint systems are provided for fall protection. Operatives maintaining the roof must wear a full body harness with two lanyards to ensure at least one is always attached.

The platform canopies are accessed via bespoke access stairs from the escape cores and paid concourses. The platform canopies are designed with a cable line restraint system on the inward side of each of the two gutters. This is to restrain the operatives from the canopy edge but also restrain them from the Overhead Catenary System (OCS) exclusion zone. Platform canopy gutters will have an anti-slip walkway and fall restraint system.

The platform canopy soffits are demountable along the width where services are provided in the roof cavity. This is accessed with a small platform lift.

All services have been positioned outside the OCS exclusion zone so this area will not require any regular access.

By ensuing good material selection with a view to low maintenance, positioning of items requiring regular access in considered easy to access locations and providing permanent means of fall protection when working at height is unavoidable the residual risk to operators and maintainers can be mitigated.

Deconstruction considerations

This section covers the design philosophies that have been considered to ensure that Interchange station and its external environment have been designed with safe deconstruction in mind.

The overall philosophy is to maximise off-site fabrication and minimise on-site operations, therefore reducing exposure to hazards and safety risks, improving quality and consistency of the delivered product and reducing the time of on-site construction. This philosophy lends itself to a ‘Design for Deconstruction’ (DfD) ethos with the ability to disassemble installed elements in the future rather than traditional demolition.

This design philosophy is made possible by the close collaboration between the Integrated Design team and the Construction Planning team, as well as effective communication with the many stakeholders and interfaces with interdependent works.

To ensure that the station materials can be safely maintained, replaced and ultimately deconstructed; the following DfD principles have been followed and should be followed going forward in further development of the design;

- Design for simultaneous, parallel disassembly and deconstruction;

- Maximise the elements of the building which are easily separable;

- Maximise the amount of structural connections which are easily accessible, minimising any requirement for enabling works;

- Minimise the quantities of material used in the construction of the building to limit the time and logistical requirements at deconstruction;

- Fix building services to the surface to allow ease of access.

- Avoid unnecessary finishes, especially in back-of-house areas;

- Avoid use of composites, which preclude segregation of materials;

- Avoid applying secondary finishes to materials, as they may cause contamination;

- Avoid toxic and hazardous materials;

- Use modular, prefabricated elements which can be easily demounted or dismantled, from finishes to entire elements of external envelope;

- Give preference to the use of concrete formed into standard components to increase the potential for reuse and recycling;

- Minimise the number of types of connectors and the number of connections;

- Design fixings, connectors and components for repeated use;

- Tag assets containing manufacturer, deconstruction and recoverability information

- Incorporate radio frequency identification devices (RFid) and e-tagging to allow the characteristics and manufacturing history of precast units to be identified at end-of-life;

Embedding an approach to safe deconstruction also enables the station to operate within a circular economy. Components and assets can be tagged as reusable, recyclable, biodegradable, hazardous or for energy recovery and segregated appropriately as deconstruction progresses. This highlights what has been commonly found across the project: that delivering a safe scheme goes a long way to deliver sustainable economic, environmental and social outcomes as well.

Conclusion

Adopting Safety by Design principles at the earliest stage has significantly contributed to the design of Interchange station as this paper demonstrates. All design decisions have been informed by these principles. Not only does this result in a building that is safer to construct but also one that will be visually arresting, cost effective and sustainable. Removing complexity is an opportunity to derive a better design, not a constraint that limits the designer’s imagination or ambition.

By considering health and safety from the outset of a project, the design can be vastly improved to reduce risks during the construction, operation, maintenance and deconstruction of both the station building and external works. Through early collaboration with specialist consultants, design decisions have been made to protect future users of the building.

The key moves which have been taken include:

- Working closely with Arup’s specialist consultants and HS2’s subject matter experts along with our subconsultants – Costain for construction logistics support, HS2’s Design Panel and external stakeholders.

- Incorporating safety, constructability and maintenance into the SIFT matrix for key decisions

- Considering CDM alongside CSM

- Moving the station building off trace

- Designing the building to be constructed with off-site, prefabricated, repeated elements using DfMA principles

- Designing all areas of the building to be accessed safely for maintenance and inspection, reducing the need to work at height.

The most significant design change which improved the safety of the station for all stages of its life was to move the station building ‘off-trace’. This means it does not sit across the tracks but instead to one side with smaller elevated walkways connecting the paid concourses to the platforms below. This removes huge complexities and risks associated with constructing a building above the high-voltage overhead catenary system (OCS). It also means that the majority of future maintenance will be done away from this high-risk area and will allow the trains to remain operational for longer.

The other key design move was to increase the use of off-site fabrication. This greatly reduced the risks of on-site construction. The reduction of time spent working onsite means the work will be completed to a higher quality standard in a safer factory setting, with fewer people and hazards on site.

The design team has taken a whole-life approach to safety and prioritised safety as the first consideration in all design decisions. This affords the greatest opportunity to influence safety for the better and avoids the increased costs of having to amend the design at a later stage of its delivery, operation or decommission. This will ensure the station will continue to achieve the highest standards of safety throughout its life.

Acknowledgements

Interchange Station SDSC: Arup, Costain, Churchman Thornhill Finch, RLB and HS2.

References

[1] High Speed Two (HS2) Ltd. (2019), HS2 Health and Safety Policy HS2-HS2-HS-POL-000-000001_P07

[2] Office of Rail and Road. (2017), ORR’s Strategy for Regulation of health and safety risks – Chapter 12: Health and Safety by Design

[3] DK&A. (2017). HS2 Design Vision. High Speed Two (HS2) Limited