Management of acoustics integration on HS2 for delivering environmental commitments

Environmental noise from the HS2 Railway is the product of the complex interaction of its constituent subsystems (i.e., train, railway systems and civil infrastructure) within the operational parameters of the railway. This paper sets out the approach for delivering the end-state HS2 railway that can operate within the noise limits of the Environmental Minimum Requirements (EMRs) as set out in the HS2 Act. This is achieved through acoustic system integration, whereby the required noise output of the integrated railway is achieved through adequately defined requirements, obligations, and interfaces, as well as the assessment of compliance evidence through a rigorous verification and validation process.

Background and industry context

Environmental Noise from HS2 is a by-product of the interaction between the constituent sub-systems (i.e., train, railway systems and civil infrastructure) within the operational and maintenance parameters of the railway. Acoustically, the HS2 railway is a very complex system and its environmental outcome/performance (e.g. the noise propagation into the railway surroundings) can be a constraint that impacts the design, construction, and operation and maintenance of the end-state railway.

This is because the envelope of environmental noise effects generated by the HS2 railway is set out in the HS2 Act and is one of the main objectives for HS2 Ltd, which is set out in the contract between HS2 and the Department of Transport (also known as development agreement [1]). This objective is to design and deliver a Railway to avoid, reduce and, if possible, remedy adverse impacts, as far as reasonably practicable (including during construction), and deliver enhancements where these are economically viable, including the following areas: Sound, Noise and Vibration.

The main question that this paper will answer is the following “”How does HS2 Ltd progressively assure that the end-state railway can deliver the sound noise and vibration commitments with the HS2 Act?”. The answer to this question lies in the relatively simple, albeit non-trivial, concept of ‘System Integration’.

Learning from previous projects, e.g., Crossrail, has shown that the inability to integrate across multiple components for a successful outcome [2] is the biggest risk on major railway projects. To manage this risk HS2 Ltd has invested in developing systems integration capability earlier than Crossrail to de-risk the delivery of the programme.

System integration is enabled by System Engineering which is a multidisciplinary field that covers the entire life cycle of a system, from conception to operation and maintenance. A system can be any combination of hardware, software, data, people, processes, and environment that work together to achieve a specific goal or function. Examples of systems are railways, aircraft, satellites, robots, networks, or software applications. There are several examples on how system integration and system engineering are applied to infrastructure projects [3], however, there is a gap in the literature on how system integration and system engineering principles can be applied to Acoustics Engineering within the delivery of major infrastructure project. This paper aims to fill this gap in knowledge.

Approach

The approach for delivering the end-state HS2 railway that can operate within the noise effects as set out in the HS2 Act is provided in this section. This is achieved through acoustic system integration, whereby the required noise output of the integrated railway is achieved through adequately defined requirements, obligations, and interfaces, as well as the assessment of compliance evidence through a rigorous verification and validation process.

HS2 commitments for noise and vibration

As mentioned above the HS2 Act sets out the envelope of noise and vibration effects for the HS2 Railway and a set out control measures for those effects as part of the Environmental Minimum Requirements (EMRs) [4].

The EMRs contain the principal control measures set out in the following noise and vibration Information Papers (IPs):

- Information Paper E20 Control of Airborne Noise from the operational railway and altered roads [5]

- Information Paper E21 Control of Ground Borne Noise and Vibration from the operational railway [6]

- Information Paper E22 Control of Noise from Stationary Systems [7]

- Information Paper F4 Operational Noise Monitoring Framework [8]

While IP F4 applies to the railway when is in operation, the first three IPs are applicable from the design to the operational (including maintenance) phases of the HS2 Railway.

The main objective of IP E20, IP E21 and IP E22 is to ensure that the different types of noise and vibration generated by the operational railway are reduced as far as reasonably practicable (AFARP).

The IPs for noise and vibration play an important part on how HS2 Ltd responds, also known as functional response, to the overall commitments sets out in the development agreement for controlling noise and vibration effects on the HS2 Railway.

The HS2 Commitments for Noise and Vibration sets out in the HS2 Act and controlled by the Noise and Vibration IPs can be considered as input or client requirements.

The IPs are also part of the register of undertakings and assurances (U&As in Figure 1). This register provides information on the commitments made in relation to the High Speed Rail which also includes Noise and Vibration.

Definition and apportionment of requirements

The first step in achieving Acoustics System Integration is to make sure that client requirements are cascaded to the supply chain (or contractor) delivering the different components / sub systems of the HS2 Railway. This is obtained through requirements definition and apportionment.

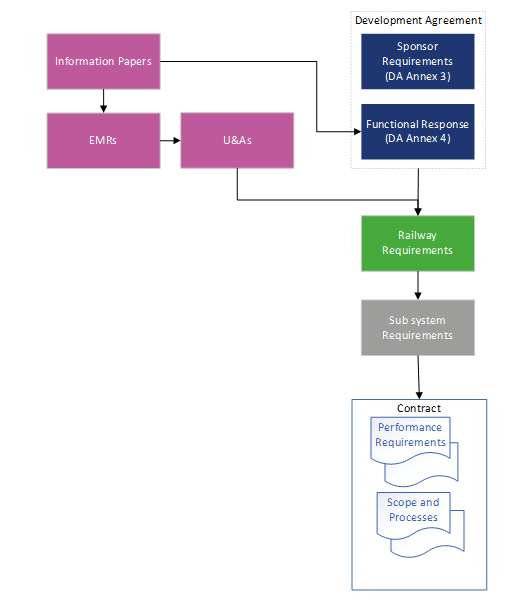

Figure 1 provide an illustration on how requirements are apportioned into a sub-system contract to be delivered by the supply chain.

The requirements for Sound, Noise, and Vibration on HS2 related to the Development Agreement and the EMRs are generally identified as Client Requirements.

The Client Requirements are then used to derive Acoustics Railway Requirements which:

- Ensure that sound, noise, and vibration effects from the HS2 railway are assessed and controlled in line with the objectives of the IPs,

- Stipulate that acoustics prediction, measurements, and design are done in line with acoustics standards.

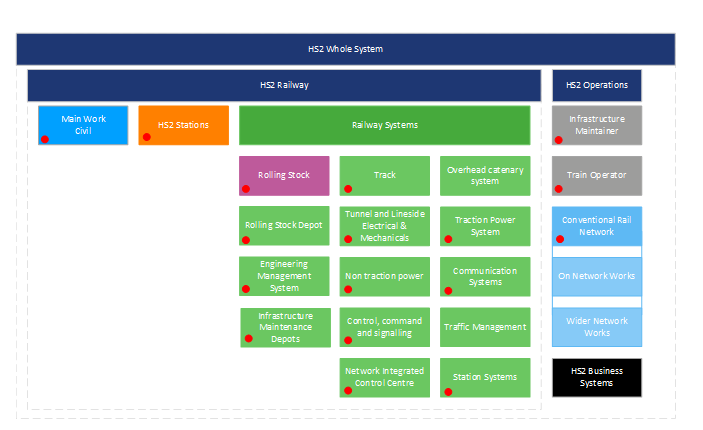

Figure 2 presents a summary of the sub-systems which form the HS2 system; those with a red dot in the lower left corner indicate sub-systems (either within HS2 Railway or HS2 Operations) which will have an emitting and/or mitigating Sound, Noise and Vibration function and will contribute to the overall acoustic performance of the HS2 Railway.

Acoustics sub system requirements are derived through modelling, analysis, and/or benchmarking. The approach used to derive sub-system requirements is dependent on the sub-systems and any associated risk of non-compliance against the EMRs. An example of sub system modelling can be found in [9] where model of the noise emission generated by the wheel-rail interaction has been used for setting out track’s acoustics performance.

Contract requirements are then linked to sub system requirements and issued to the supply chain delivering the HS2 programme. Contract requirements can be classified in three broad categories: Performance, Scope and Process Requirements. An example of performance requirements is the Train Technical Specification [10] which includes a set of acoustics requirements for rolling stock.

Acoustics V-lifecycle activities

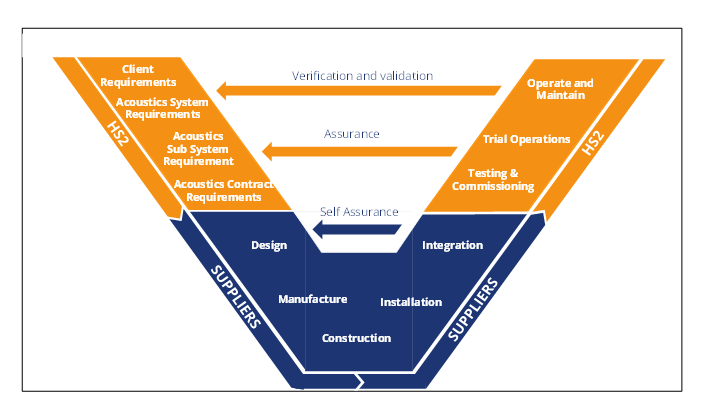

Once requirements are allocated from Client to Contract level, another important element for achieving Acoustics Integration are the Verification and Validation (V&V) activities which will demonstrate that both acoustics subsystem and system requirements are met. These activities are undertaken through the entire lifecycle of the railway also known as “V cycle”. The latter is a model taken from EN 50126:2017 applied to system integration and Figure 3 shows how the V-life cycle applies to Acoustics Engineering. Figure 3 also provides a split between contractors and HS2 activities.

V&V activities are provided at the sub-system and contract levels as well as system level, with the former providing evidence to building the assurance case of the latter.

The proceeding sections will provide an explanation of how sub-system and system assurance works for acoustics. The evidence provided by the supply chain to comply with contract requirements are key to these processes.

Subsystem/Contract assurance

Acoustics is a transversal / cross-cutting discipline which includes contributions from a wide range of sub-systems / contracts across the programme.

Contract requirements and their validation is achieved through the V&V cycle of the railway. The V&V cycle comprises of the different design stages which are: Design, Manufacturing, Construction, Installation, and Testing and Commissioning.

At contract level contractors’ assurance for acoustics is based on risk and occurs primarily through:

- Attendance and participation at design reviews and contributing to the auditing process,

- Reviewing and accepting contractors’ deliverables against their scope and requirements,

- Resolution of early warning notices (EWN), technical queries (TQs) and requests for information (RFIs) pertaining to the delivery of the acoustics programme.

The expected compliance evidence (deliverables) is defined through the acceptance criteria associated with the acoustics requirements, including noise and vibration management plans, assessment methodology and assumptions reports, assessment and design reports, test reports etc.

HS2 Ltd is ultimately responsible for the compliance with system and client requirements related to Sound Noise and Vibration, but contractors support HS2 Ltd by:

- participating in a programme of sound and vibration prediction, assessment and measurement that affects the design, construction planning, testing, commissioning, and authorisation of the sub-system,

- contributing to the achievement of system-level capabilities (see section below) through their design, when combined with the design of others, including meeting requirements specified in their contracts including EMRs,

- providing data and evidence in relation to their design to inform the achievement of the EMRs.

System assurance

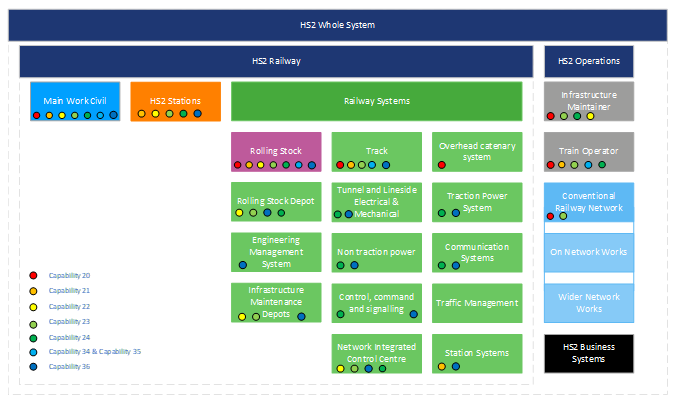

The acoustic performance of the HS2 railway is a measurable outcome which has been defined in terms of capability of the HS2 system. There are eight capabilities related to acoustics: five (Capability 20, 21, 22, 23 and 24) associated with the operating environment of the railway linked with IPs control measure and three (Capability 34, 35 and 36) associated with passenger experience and comfort.

Figure 4 provides an indication on how the different sub-systems contribute to the different acoustics capabilities. This highlights the complexity of the Acoustic engineering discipline, due to the interface and interaction among the different sub-systems under operational and maintenance rules. Because of its multi-disciplinary nature, the delivery of the acoustics capabilities, and associated system requirements, cannot be achieved through contracts/subsystem requirements alone; therefore, acoustic system integration is also needed.

To ensure that Acoustics Capabilities are met by the HS2 railway, interfaces are defined and agreed between sub-systems/contracts together with system integration obligations between the sub-systems/contracts and HS2 Ltd acting as the Prime System Integrator.

Throughout the railway lifecycle, acoustics system integration is achieved through active integration of the acoustics capabilities and through the following processes/functions:

- Ensuring that the contractors/designers required to fulfil the acoustic requirements conduct their design and assessments, including all the sub-system contributions and operational assumptions and is fully integrated with other contracts.

- Ensuring that changes in assumptions/requirements in the contractor scope do not have an impact on other sub-systems and in the delivery of the acoustics Capabilities. This is generally achieved through assessing the impact of changes in assumptions through specific analysis and modelling tasks and, where necessary, providing recommendations for any scope change in sub-system contracts for ensuring that the acoustics capabilities are still delivered.

- Active management of acoustics risks through analysis and modelling tasks and, where necessary, to provide recommendations for any scope change in sub-system contract to HS2 for reducing risk of not delivering the acoustics capabilities.

- Validate that acoustics system requirements are met through testing and commissioning activities.

The progressive delivery of the acoustics capability provides confidence to HS2 Ltd that the operation of the integrated railway can:

- achieve compliance with the HS2 Environmental Minimum Requirements (EMRs) and

- deliver acoustic comfort for passengers, HS2 staff, and those living and working around the railway.

The body of evidence demonstrating that the acoustics system requirements are met through the capability is called system assurance.

Outcomes

A system integration approach is being adopted to ensure that the HS2 Railway is progressively demonstrating that its noise and vibration outcome is delivered within the constraints set out in the HS2 Act. The approach is actively used to reduce any risk of non-compliance with Noise and Vibration EMRs for the end state of the railway.

Learnings and recommendations

This paper addresses the gap in knowledge for the application of system engineering and system integration principles which can be applied to major infrastructure project to ensure that complex environmental outcome like noise and vibration can be delivered within the envelope of the environmental noise effects identified at the development stage of the scheme. The authors hope that this approach can be used and developed further for other major infrastructure project where the noise outcome is generated by the multiple interactions of its subsystems.

Conclusion

A system engineering approach based on system integration has been presented to ensure that the noise and vibration outcome of the HS2 Railway is within the environmental noise effects identified with the HS2 Act. To achieve Acoustics System Integration for the HS2 railway, requirements have been defined from Client to Contract level passing from the Railway level requirements to the Subsystems which contribute to the sound, noise and vibration of the Railway. A robust set of V&V activities at Subsystems level are needed in order to assure that contractual requirements are met. Due to the complex nature of Acoustics, a set of V&V activities at Railway level are also needed in order to ensure that interaction/interface among the different sub-systems achieve the desired environmental outcome in line with HS2 EMRs. In this sense system integration concepts like railway performance output or capability are useful to provide progressive system assurance that the noise and vibration emission of the HS2 railway is line with the HS2 EMRs.

Acknowledgements

The author wants to acknowledge the HS2 System Integration Department and the HS2 Capability and Functionality Team.

References

[1] “Policy Paper HS2 Development Agreement,” 21 February 2024. [Online].

[2] House of Commons Committe of Public Accounts, “Completing Crossrail,” 2019 July 10. [Online]. [Accessed 21 February 2024].

[3] The Institution of Civil Engineers (ICE) M. A, “A Systems Approach to Infrastructure Delivery,” 28 April 2022. [Online]. [Accessed 21 02 2022].

[4] HS2 Ltd, “Environmental minimum requirements for HS2 Phase One,” 25 11 2013. [Online]. [Accessed 28 05 2024].

[5] HS2 Ltd, “HS2 Phase One information papers: environment (series E), Control of airborne noise from altered roads and the operational railway” 30 07 2014. [Online]. [Accessed 28 05 2024].

[6] HS2 Ltd, “HS2 Phase One information papers: environment (series E), Control of ground borne noise and vibration from the operation of temporary and permanent railways” 30 07 2014. [Online]. [Accessed 28 05 2024].

[7] “HS2 Phase One information papers: environment (series E) Control of noise from the operation of stationary systems,” 30 07 2014. [Online]. [Accessed 28 05 2024].

[8] “HS2 Phase One information papers: Operational noise and vibration monitoring framework (F4)” 13 05 2014. [Online]. [Accessed 28 05 2024].

[9] O. Bewes, G. Sica, M. Towards and D. Thompson, “Prediction of rolling noise from ballast and slab track at speeds up to 360km/h,” in World Congress on Railway Research, Birmingham, 2022.

[10] HS2 Ltd, “Train Technical Specification,” 15 March 2019. [Online]. [Accessed 21 February 2024].