Minimisation of spoil to landfill from a collaborative approach to re-use on site

The High Speed Two (HS2) affordability challenge launched in November 2018 was the springboard to new ideas to change the scheme in the West Ruislip area. The idea was named the NEMO concept (New Excavated Material Opportunities). NEMO achieves a 3% carbon reduction, avoids 400k m3 of excavated material and removes 1.35M m3 of off-site disposal, with significant cost, programme, community and environmental benefits.

The idea works by replacing a large cutting with a cut and cover tunnel, reinstating the countryside over this tunnel to return to the local community, a shortening of the West Ruislip Portal to shorten the critical path of the tunnelling, and reconfiguring existing rail sidings at West Ruislip for use during the construction. This eliminated the need for an even larger temporary railhead at Copthall Cutting, which was the basis of the hybrid bill design.

As shown in this paper, a holistic approach to the design has led to a combination of ideas coming together to achieve one big idea that delivers more than the individual parts. This paper explains the full story of NEMO, as well as all the benefits it will deliver once fully implemented.

Introduction

This paper is presented as part of the works to deliver the southern section of High Speed Two (HS2) Phase One – Lots S1 and S2 (Area South) – which includes the Northolt Tunnels and the Euston Tunnel and Approaches, being delivered by the SCS Integrated Project Team

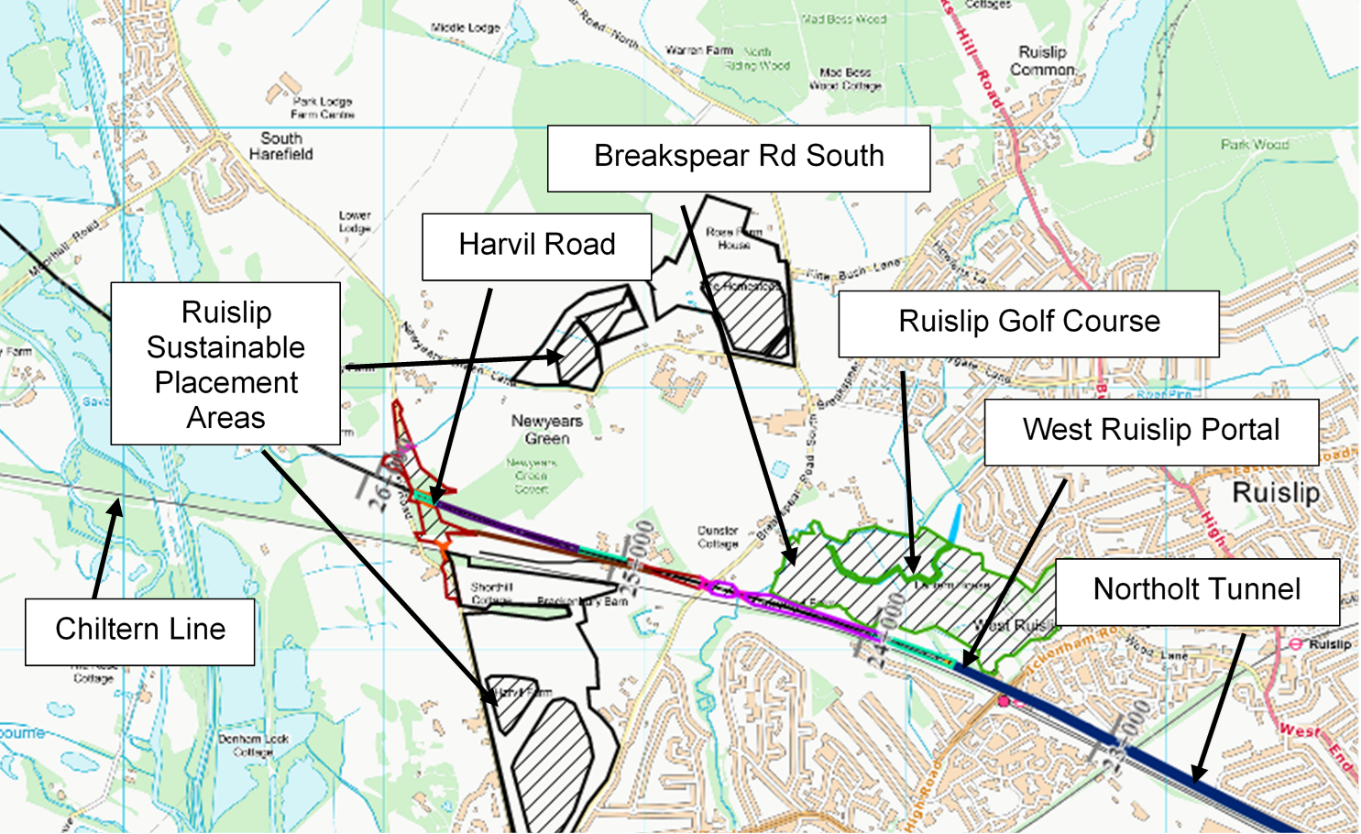

The NEMO scheme relates to the West Ruislip area of S2, where the Northolt Tunnels West transition into open route via the West Ruislip Portal. The geography transitions from urban, through suburban and into a rural area. The HS2 route runs in parallel with the existing Network Rail Chiltern Line, which runs at surface level, over embankments and into cuttings. Figure 1 shows the West Ruislip area.

The HS2 Project has faced opposition in this area from the local authority (London Borough of Hillingdon), residents’ associations and protesters’ encampments. Despite maximising the use of rail freight, the HS2 works will require a large number of vehicle movements on the local roads, many of which are minor rural routes; and the opportunity to significantly reduce vehicle movements through the NEMO scheme will have a substantial positive impact on the local community.

Background

Hybrid Bill Design

From Old Oak Common, the alignment of the HS2 tracks are either below or adjacent to the Network Rail Chiltern Line. At West Ruislip, the HS2 tracks come out of the ground at the West Ruislip Portal and then as they pass above ground, start to peel away from the Chiltern Line as the alignment heads over into the Chilterns and Birmingham beyond. At this intersection point, where the two alignments peel away, the HS2 tracks must pass through a 25m high hillside.

In the hybrid Bill design, the arrangement chosen was a large 1 in 4 slope cutting with the space between the HS2 and the Chiltern Line fully excavated out to make way for a construction railhead as indicated in Figure 2.

This railhead needed to support the following three functions:

- To deliver tunnel segments to the railhead, that would then be transported over the HS2 embankments to the portal area 1500m away.

- To export tunnelling spoil that had come from the portal via conveyors.

- To be used by the Rail Systems contractor to fit out the railway.

In the permanent case, the temporary railhead would be converted to a simple siding that could be used to park a maintenance train overnight.

At the time, great emphasis was made to make best use of the railhead to limit vehicle movements on the local roads that would affect the local community for a number of years.

A key theme to this paper is that West Ruislip is not a series of individual structures or elements, but a series of interconnected elements that are a product of the overall tunnel construction strategy. At this point it is worth explaining the original tunnelling strategy for the Northolt Tunnel.

- Excavate the Copthall Cutting during the first earthworks season to make space for the railhead. As there is no railhead at this point, the material that comes out of the cutting is placed on local areas known as the Ruislip Sustainable Placements (RSP) immediately to the north and south of the HS2 alignment.

- In parallel, construct the West Ruislip Portal, and the HS2 embankments and earthworks between the portal and the cutting. These structures are critical to support the tunnelling logistics corridor between the railhead and the tunnel portal.

- In the second earthworks season excavate the remainder of the cutting, but the spoil is exported via the railhead instead of to local deposition sites.

- At the portal, a pair of TBMs are launched towards Greenpark Way Shaft. As already mentioned, the tunnel segments are delivered from the railhead via the HS2 embankments and bridges. Tunnel spoil is removed by conveyors towards the railhead, where it is first treated to make more workable, before being exporting via the railhead.

As can be seen the success of the S2 contract is heavily reliant on the West Ruislip area being up and running early to support the critical path of the Northolt Tunnel operations.

The SCS Scheme Design

Upon appointment, SCS developed an optioneering process that aligned with the assurance process and included stakeholder input. The focus was mostly on the major cost items and the West Ruislip area was identified as key to success. Workshops were held with designers, construction specialists and the HS2 client. Each element of the West Ruislip area was considered over a series of structured workshops. All ideas and options were on the table, but no ideas were taken forward if they did not fully meet HS2 requirements or the assurances in the hybrid Bill. The following table summarises some of the main elements in the West Ruislip Area and identifies the key developments of the SCS design.

| Element / Idea | Hybrid Bill Design | Scheme Development |

|---|---|---|

|

West Ruislip Portal |

A 440m long portal structure formed with diaphragm walls and a cast in-situ base and roof slab. |

The diaphragm walls were replaced with contiguous piles with a liner wall. These were considered more effective to install for the ground conditions. |

|

Copthall Cutting |

1:4 slope | A number of options were looked at to improve the slope angle to reduce cut volumes. Due to the presence of relic shear surfaces in the clay the 1:4 slope was considered the most cost-effective approach. Since the hybrid Bill design had allowed for the space taken by the former Heathrow spur, some saving on the earthworks volumes was achieved by bringing the cut closer to the main line. |

|

Ruislip Sustainable Placements |

Both north and south RSP had a maximum height of 3m. | As the wishes of local landowners and other constraints were built into the SPA design, higher RSPs over a smaller area were preferred to the hybrid Bill arrangement. The Northern RSP had a height of 18m. |

|

Extend tunnel length to a portal at Harvil Road. |

Northolt Tunnel terminated at a Portal by the Ickenham High Road. |

An option was looked at to extend the tunnel to a portal at Harvil Rd. This was not taken forward because it was not decisively cost effective. |

|

Replace the Copthall Cutting with an open trough structure |

1:4 slope |

The proposal was a diaphragm wall propped trough. This option did not offer major savings as a significant excavation of cut was still required to form the temporary railhead. |

The One Team Challenge

Following completion of the scheme design, towards the end of 2018 HS2 launched the One Team Challenge. This was a period to challenge the SCS and HS2 team to become more closely aligned and help the project deliver savings, with a focus on a “one team” mentality.

The scheme design stage of the project that had just passed was very much focussed on delivering a scheme that met all HS2 requirements and was fully compliant with the HS2 Act. However, what if specific requirements could be challenged? Could a small amendment to the requirements unlock significant value? Was that requirement offering good value? With the team given permission to go outside the box and to be given free rein to transcend disciplines; it was in this collaborative climate that the idea of New Excavated Material Opportunities (NEMO) was realised.

The NEMO Concept

Introduction

The NEMO concept is a multi-disciplinary approach to dealing with the large volumes of material excavated around West Ruislip – either from the large excavations of the Copthall Cutting and the West Ruislip Portal, or from the twin tunnel drives of the Northolt Tunnel. It also sought to take value engineering ideas of relatively low cost and to combine them into one idea that delivered more than the individual parts.

Two main threads to the concept was firstly the time taken to construct the West Ruislip Portal and all the supporting infrastructure to maintain tunnelling operations, and secondly, the cost and management of exported material.

West Ruislip Portal Value Engineering

The West Ruislip Portal to the Northolt Tunnel West is the type of portal that dives down into relatively flat terrain. The length of the portal was originally dictated by two factors:

- The headwall at the deepest section was located at a position where there was sufficient over-burden to the tunnel such that there was no blow-out due to the pressurisation of the Tunnel Boring Machine (TBM) face and also that there was enough weight above the tunnel such that there was no risk of long-term buoyancy of the tunnel.

- The overall length of the cut and cover part of the portal was driven by acoustic requirements driven by the need to avoid micro-pressure waves creating by high-speed trains entering and exiting tunnels. These micro-pressure waves can result in a loud sonic-boom type noise.

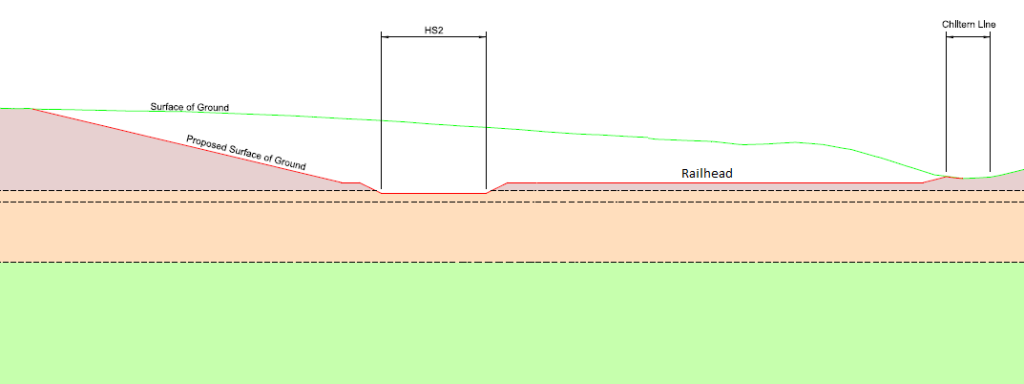

As there were significant volumes of excavated material available at the site, an idea was developed to cover the portal site forward of the headwall in 5m of spoil. In doing this the headwall could be moved back up the alignment by 140m, and yet maintain enough over burden to the tunnel from the artificially raised ground. This had the effect of shortening the overall length of the portal and removed the deepest, costliest and most time-consuming to construct part of the portal. Individually this is a beneficial approach, but the TBM could not launch approximately 6 months earlier because without all the tunnel logistics set-up via the Copthall Cutting railhead, the TBM was unable to advance.

Figure 3 shows an elevation of the portal and the effect of the 140m shift of headwall.

The Cost of Exported Material

What started out as an attempt to make best use of excavated materials ultimately unlocked the programme advantage at the portal.

In principle, the hybrid Bill and scheme design approach to construct a railhead to export tunnel spoil has merits as it takes vehicles off the road in a relatively environmentally friendly way. The consequence though is that the material is being exported to landfill at great cost – four times what it costs to use locally within the scheme. Removing spoil out of the area is one approach, but a preferred approach would be to re-use the material locally as engineering fill or in landscape applications to better enhance the local experience. The quest started out to maximise ways of using cut material in more useful ways as that cut material has value.

Table 2 shows the cut and fill volumes from the scheme design. This shows that the balance between material re-used locally and material exported was 43% / 57%.

| Source | Export by Rail (m3) | Local Re-use (m3) |

|---|---|---|

|

Northolt Tunnel |

1,200,000 |

– |

|

Copthall Cutting (and railhead) |

200,000 |

1,000,000 |

|

West Ruislip Portal |

– |

50,000 |

|

Total |

1,400,000 |

1,050,000 |

An early idea that was explored was the local golf courses in the area. There was an Undertaking and Assurance (U&A) commitment to re-use excavated material from the portal construction to redevelop the Ruislip Golf Course adjacent to the portal site. As part of the original hybrid Bill design there was also a plan to use the Uxbridge golf course as a haul road. This was never taken up, but one approach would be to re-develop the golf course using material that would have been exported. In the end the re-development of the Uxbridge Golf Course was not followed through, but this could be something to consider in Phase Two of the route where the costs of exporting spoil may be offset by the re-development of a local golf course.

Another stream that was explored was to maximise the use of the RSPs. In developing the scheme design the volumes of the RSPs had been reduced by 10% at the expense of exported material. Rather than reduce the size of the RSPs to export material, the team considered maximising the RSPs, within the limits of the Act, to reduce the amount of exported material. As shown in Table 2 there is a lot of locally excavated material to create the temporary railhead. As further ways of re-using material locally were identified, the reason for the railhead was becoming less justified. Simplistically, the Copthall Cutting railhead is a 1.2M m3 excavation to make space to export 1.2M m3 of tunnel spoil. This resulted in the team questioning, “What if we deleted the railhead?”.

Eight out of the 10 sidings of the railhead were needed for export of spoil. If tunnel spoil was used instead for the RSPs then how could the tunnel segments be delivered? Fortuitously at the time, HS2 and Network Rail were decommissioning a pair of sidings next to the West Ruislip Portal that go onto the Chiltern Line. One of those sidings had to go to make way for the portal, but the remaining siding could be extended to deliver segments right to the portal mouth. Logistically this was superior to what was originally proposed, and furthermore, the connections onto the Chiltern Line were already in place and there would be limited disruption to existing passenger services.

Now that the railhead at Copthall was gone this eliminated the need for all the new Network Rail works associated with making the connections to the Network Rail Chiltern Line. Also, because of the way the original railhead was configured, the eastbound exit from the facility went adjacent to the HS2 line from Copthall Cutting to the Portal. This meant the HS2 embankments and two underbridges were widened to three tracks for the construction stage but were over providing in the long-term. By re-locating the railhead, all the embankments and bridges could be reduced in width.

With all these pieces coming together there was still the challenge of how to get the HS2 mainline through the Copthall hillside. To maximise the use of excavated material a cut and over tunnel structure was identified as the way forward. This was the final piece of the jigsaw to come together, as what was once a large scar on the hillside, allowed the project to restore the landscape in the area for the use of the local community.

One final positive feature of the NEMO scheme was to lift the alignment over Breakspear Rd by 1m, which avoided the need for a highly disruptive road lowering operation below the HS2 mainline.

In summary, the key features of NEMO are:

- Shift the headwall of the West Ruislip Portal 140m west.

- Delete the temporary railhead at the Copthall Cutting.

- Use the existing siding at the portal for tunnel segment delivery.

- Delete all the Network Rail connection works.

- Lift the alignment by 1m at Breakspear Rd South.

- Adopt a naturally ventilated cut and cover tunnel instead of Copthall Cutting.

- Make all the HS2 bridges and embankment narrower to just support the HS2 mainline tracks.

Table 3 shows the earthworks volume comparison between scheme design and the revised volumes following the One Team Challenge.

| Scheme Design Volumes (m3) | NEMO Volumes (m3) | |

|---|---|---|

|

Cuts (Excavated Material) – Northolt Tunnel – West Ruislip Portal – Copthall Cutting – Copthall Tunnel Total |

1,200,000 50,000 1,200,000 – 2,450,000 |

1,200,000 50,000 – 830,000 2,080,000 |

|

Fills / Exports – Ruislip Golf Course – West Ruislip Portal Landscape – Northern SPA – Southern SPA – Harvil Rd Highway Works – C1 ATFS Site – Copthall Tunnel – Export by Rail – Contingency Total |

50,000 10,000 500,000 350,000 200,000 – – 1,340,000 – 2,450,000 |

50,000 20,000 570,000 370,000 115,000 20,000 700,000 – 235,000 2,080,000 |

Going back to the West Ruislip Portal Value Engineering, the changes to the tunnelling logistics set-up meant that the programme savings at the portal could be realised into an overall programme saving. It also meant that as there was already a siding set up from day one of construction, the West Ruislip Portal railhead could be used to deliver materials for the construction of the portal, embankments and bridges, thus taking more vehicles off the road.

NEMO Benefits Summary

The NEMO scheme realises the following benefits to the project, the local area and HS2 as a whole, when compared with the scheme design:

- Reduces the volume of material exported from the West Ruislip area by approximately 1.35 million cubic metres.

- Reduces the volume of excavated materials by approximately 400 thousand cubic metres.

- Reinstates the rural landscape over the Copthall Tunnel for community benefit and reduces operational noise levels.

- Reduces vehicle movements using the Swakely’s roundabout (a critical part of the local road network) by approximately 15,000 movements.

- Provides approximately 27,000 tCO2e reduction in carbon (3% across the S1 and S2 contracts).

- Achieves a significant reduction in cost by reducing earthwork movements, minimising disposal to landfill and by reducing the overall contract programme length by six months.

West Ruislip Portal

As discussed, in order to reduce the total excavation for the West Ruislip Portal, the headwall was moved 140m westwards along the alignment. This reduced the depth of the structure by 5m and reduced the length and depth of the contiguous piled walls. The total portal length was reduced from 440m to 300m, retaining the length of the porous cut and cover section at 175m long.

This had the following benefits:

- Reduced works to be delivered by Network Rail.

- The TBM could be launched directly from the portal rather than being setup in a confined space.

- The TBM operations could take place while the portal roof was constructed overhead.

- Tunnel segments can be loaded directly on the back of the TBM.

- The TBM could be launched much earlier.

As a result, the duration of works at the portal was reduced to bring the ‘Ready for TBM’ date earlier in the programme by six months, from August 2021 to February 2021.

The HS2 hybrid Bill defines the Limits of Deviation (LOD), within which the scheduled works (listed within the Bill) may be constructed. The horizontal boundaries are strict limits whereas the vertical boundaries permit deviation of up to 3m vertically. The proposed portal move was within the horizontal corridor of the LOD and HS2 confirmed that the relocated headhouse was within the permitted limits of the vertical LOD of the portal headhouse.

A further benefit in moving the portal westwards resulted in the headhouse becoming less visible from the main local viewpoint on the Ickenham High Road, which was perceived by the local council and residents as a positive change. Subsequently, the Schedule 17 planning consent application covering the West Ruislip Portal was approved on 22nd May 2020; the first HS2 Schedule 17 to be approved by the London Borough of Hillingdon.

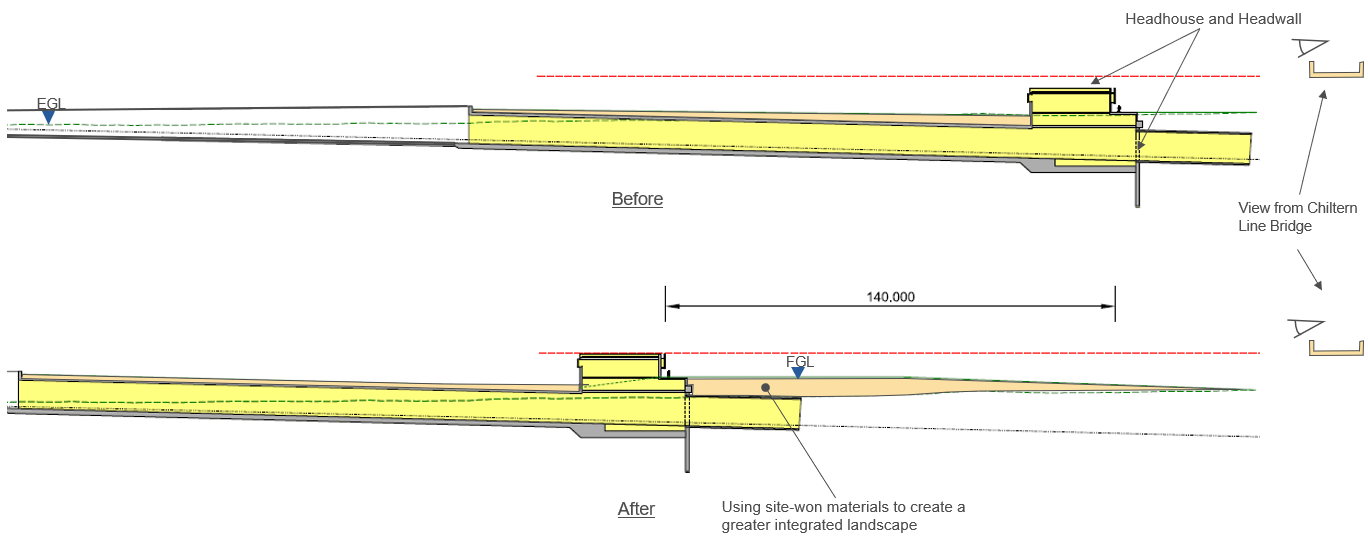

Copthall Tunnel

The Copthall Tunnel is a 550m long cut and cover structure with approximately 285m of open trough section at the portals, also encompassing an overbridge for Harvil Road at the western extent. To counteract the unloading effect of the removal of London Clay and limit long term heave to within acceptable levels, backfill is required above the tunnel. This backfill is profiled to fit in with the existing landscape. The open trough sections incorporate ‘wings’ on the base slab and tension piles to resist uplift pressures. The design includes several natural ventilation ‘chimneys’ along the centreline, which provide the necessary smoke control within the tunnel in the event of an emergency. This has avoided the need for tunnel ventilation equipment and greatly reduces the footprint of the tunnel mechanical and electrical systems at the portal building.

Originally, the tunnel backfill comprised two sources of material – natural London Clay from the initial excavation was proposed for the immediate surround to the tunnel, with the material above planned to be tunnel spoil from the Northolt Tunnels. The challenge with this was that the material available from the cut will be available long before the tunnel has been constructed and is ready for backfilling, presenting inefficient handling of material and requiring longer term storage. The solution has since been further optimised to incorporate re-use of tunnel spoil material, with the natural London Clay being used elsewhere in the area, such as the northern Sustainable Placement. Figure 4 shows a general overview of the arrangement of the Copthall Tunnel.

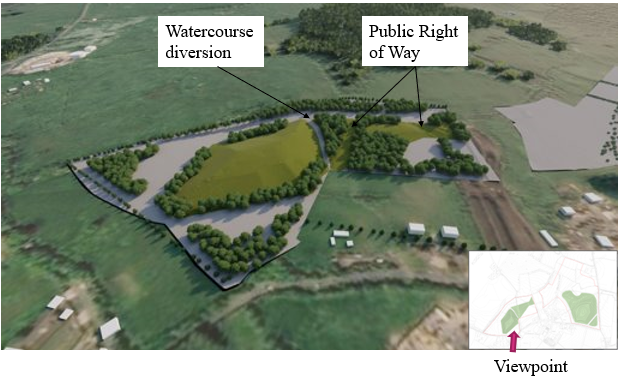

Compared to the Environmental Statement (ES), the revised Copthall Tunnel is anticipated to reduce the landscape and visual impact both during construction and operation. The final landscape design will be returned to existing condition and fit in with the local topography, whilst providing opportunity for improved footpath links across the site and connectivity with the woodland habitats to the north.

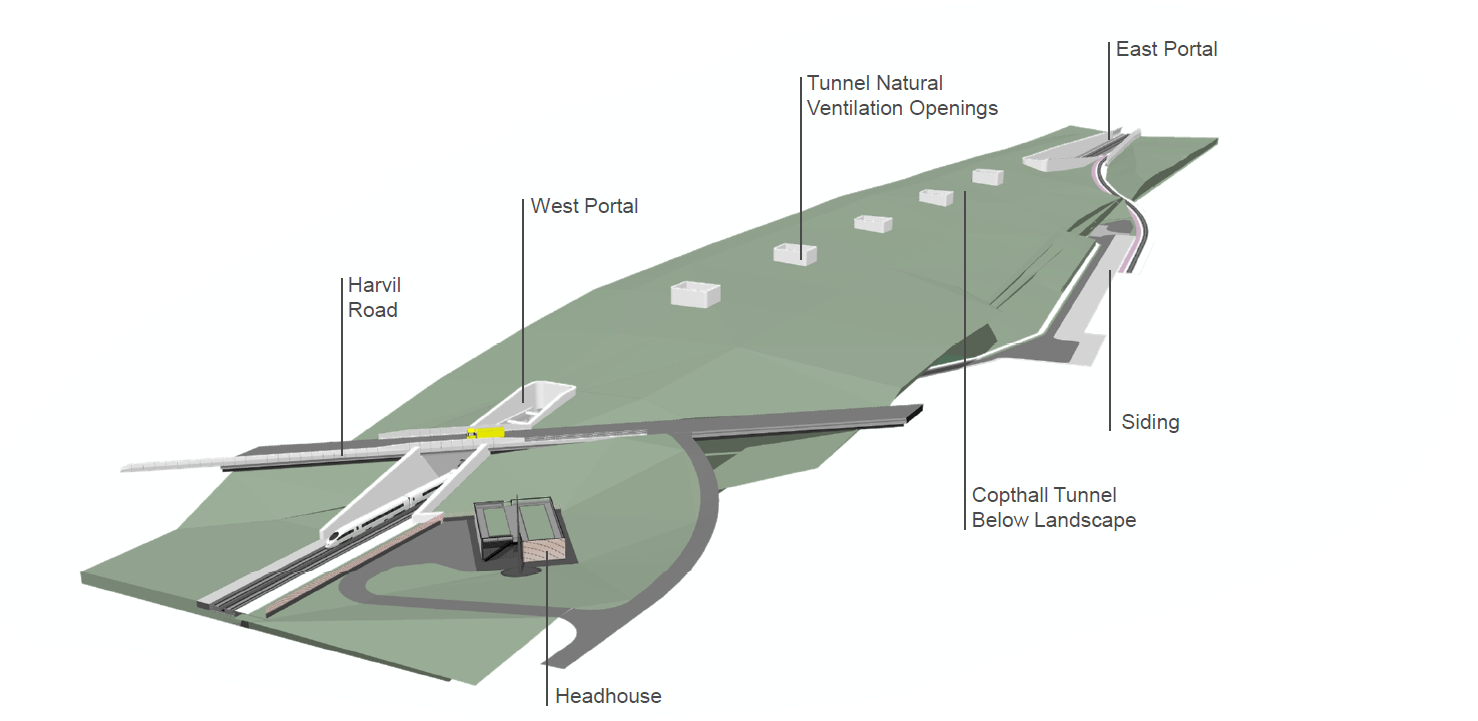

Sustainable Placements

The Ruislip Sustainable Placements (RSP) comprise three separate landscaped earthworks areas, two in the north and one to the south of the HS2 route. They provide on-site disposal of approximately 1 million m3 surplus excavated material to avoid causing environmental effects which would otherwise have been associated with transport and disposal of that material further afield. The northern mounds extend up to 17m at their highest point with a maximum slope of 1:3, whereas the southern mound is much flatter, at approximately 3m. Figure 5 shows a visualisation of the north western mound.

The Northern RSP will be formed of natural London Clay excavated from Copthall Tunnel. The Southern RSP is intended to be spoil material from the Northolt Tunnels. In terms of placement, this proves more challenging due to relatively unknown material properties. The material will be a mixture of all geologies from London Clay, Harwich Formation, Lambeth Group and Chalk, mixed with tunnel additives, water and potentially requiring some stabilisation to ensure the tunnel spoil can be transported to the new site.

The RSPs are subject to a range of design constraints and consenting challenges. The sites are bound by gas main and water main easements, exclusion zones for nearby properties, listed buildings and key environmental receptors, in a groundwater Source Protection Zone and where localised flooding is not uncommon. The design is a careful balance of maintaining required volumes whilst ensuring and improving where possible existing woodland, drainage, planting, ponds and ecological corridors in a solution which is in keeping with the local surroundings and topography. A Waste Permit Application is being submitted to the Environment Agency for each area with applications under Schedule 17 (Planning Conditions) and Schedule 33 (Protective Provisions) of the HS2 Act[1] made to the Local Authority, in this case, London Borough of Hillingdon. Consultation with other third parties, for example Colne Valley Regional Park and utilities owners has also been undertaken throughout the design.

Rail Logistics

As discussed, the original plan was to excavate an area for the railhead at the Copthall Cutting. This railhead was to service the requirements of the tunnelling operations and ensure that at no point was the project delayed due to unplanned stoppages. The terminal was dual purpose – it was to be designed to manage the spoil created by tunnelling and also to accept and store the ring segments to line the tunnel.

The terminal had to be able to accommodate the rail requirements for both the tunnelling long term average and any spikes in production. That is to say, it should be designed to be able to flex to meet these requirements. The job would stop if the tunnelling rate increased and there were no rings or the rail terminal reached safe storage capacity.

There are other variables within this mix too. The terminal had to be designed to accommodate the maximum number of trains per day. This was because at the start of the project there was no data on what times SCS would be able to send trains onto the network or receive them back. There was also no data on destinations and the length of time it would take to undertake a round trip. At no point could the terminal get locked up and there must always be space to move trains to depart, or accept a train in.

One of the key interfaces and risks identified was with establishing new connections onto the Chiltern Line for rail movements to the North and South. This became the biggest logistical risk for the project to proceed as SCS were reliant on the Network Rail works being delivered on time.

With the One Team Challenge, ideas were generated that had been constrained before. It became clear that reducing the size of the Copthall Cutting excavation could save money. However, just making the railhead smaller, would perhaps save some money in excavation, but this would be lost in risk mitigation as the operability and capacity to flex would be lost. This in turn would constrain the tunnelling operation.

It became clear that the best thing to do from a logistics viewpoint was to remove this risk and design out the requirement for the railhead in this location. Through the NEMO design there was a removal of the requirement to remove spoil by rail, however there was still a requirement to deliver tunnel segments. The challenge was to identify where we could offload segments without having to go through a multiyear Network Rail design process.

A pair of existing sidings next to the West Ruislip Portal were quickly identified as ideal for delivery of segments due to its proximity to the tunnelling operations. These were initially planned to be removed by Network Rail in their scope of works. This scope was then changed. Retaining the sidings did require some redesign as Network Rail assets needed to be moved, and instead of being above ground, these needed to be put into undertrack crossings.

Once this possible location was identified it was checked from an operational design viewpoint. This included whether there was enough space to lay a siding and what were the gradients interfaces. Through creating a number of conceptual designs, it became apparent that the best location was to extend the siding along the side of the portal and then swing it onto the trace. This would provide a siding and a second line to manoeuvre locomotives to operate the trains. A temporary embankment and segment storage yard were then developed on the mainline trace and behind the portal.

Conclusion

By working together as an integrated project team of client, contractor and designer, HS2, SCS and the Design House successfully challenged the concept design in West Ruislip and reimagined the logistics arrangements to deliver significant cost, programme and environmental benefits in the NEMO scheme.

A key lesson learnt as part of this scheme and the overall affordability challenge is that by putting a defined period of time in the programme to divert the attention of a combined group of experts from the client, contractor and designer towards imagining new solutions can result in exceptional outcomes.

Integrated thinking on earth movements is a key part of a delivering a project like HS2, but when the costs of such movements are high, then there is value in investing extra time and effort to ensure that the right solution has been established for the project.

References

Peer review

- Paul Lippitt, Waste and Materials Recovery ManagerHS2 Ltd

- Lisa Ithurralde, Sustainability SpecialistHS2 Ltd