Minimising carbon emissions at HS2 Phase One Stations

The High Speed Two (HS2) Sustainability Policy sets out the programme’s ambition to build the most sustainable high-speed railway of its kind in the world. The Phase One stations are at the forefront of this ambition and will provide new transport hubs in both Birmingham and London. Phase One stations are tasked with achieving net zero regulated emissions and a 50% reduction in whole-life carbon emissions against a baseline for a typical station.

The design teams working on the four Phase One stations – Interchange, Birmingham Curzon Street, Old Oak Common and Euston – have risen to this challenge and developed design solutions which achieve these ambitions through the use of renewable technologies and lean design as well as achieving a sustainable design in the round, as exemplified by the BREEAM Outstanding certificate for Interchange Station achieved at design stage, a first for a railway station in the UK.

This paper explores the design features that have contributed to achieving these targets as well as how the enabling works contractors currently working at the station sites are contributing to further minimising carbon emissions.

The paper provides a learning legacy for the industry showing how setting ambitious targets and requirements for contractors can drive low carbon, sustainable design.

Introduction

High Speed Two (HS2) will play a key role in enabling the UK’s transition to a net zero carbon economy through providing a low carbon transport mode for long distance journeys. This isn’t only through the operation of the trains but also how the project is designed and constructed and how the stations are operated. This paper explores how HS2’s Phase One stations’ designs are developing to be amongst the most sustainable in the world and will contribute to delivering a low carbon future.

Context

Climate change has long been recognised as a major global challenge and one that requires international cooperation as well as significant action at a national level to address. In recent years this need for action has become ever more focused as the effects of climate change begin to become more visible. This has resulted in the legally binding global climate change agreement – the Paris Agreement – adopted in December 2015 at the Paris climate conference (COP21). The Paris Agreement commits governments to the long-term goal of keeping the increase in global average temperatures well below 2oC above pre-industrial levels with the aim to limit the increase to 1.5oC since this would significantly reduce the risks and impacts of climate change[[1]].

Prior to the Paris Agreement the UK Climate Change Act (2008) had already set a target of an 80% reduction in emissions by 2050 from a 1990 baseline. This was updated in 2019 to a 100% reduction – enshrining the UK’s path to a net zero carbon economy into the law[[2]]. In addition, the EU Energy Performance of Buildings Directive of 2010 (2010/31/EU) required that from 31 December 2020 all new buildings must be nearly-zero energy buildings[[3]].

In 2013, the UK Government published its Infrastructure Carbon Review (ICR) which, building on previous studies, makes it clear that reducing carbon reduces costs and pursing a low carbon agenda stimulates innovation[[4]]. HS2 and its tier 1 contractors are all signatories of the ICR Statement of Endorsement. It is against this regulatory backdrop and emerging legislation that HS2 set its technical requirements.

In response to the various policy drivers, the built environment sector has been grappling with the challenge of how to deliver a net zero-carbon building for some time. In the UK emissions from buildings account for approximately 34% of total GHG emissions[[5]]. Whilst the majority of these emissions (around two-thirds) are from residential buildings the remaining third is still not insignificant. With development on the scale of HS2 stations these buildings have the potential to have a very significant energy demand.

In addition to the operational energy demand, contributing to the UK’s Scope 1 and 2 carbon emissions (direct emissions from the combustion of fossil fuels and other GHG releases and indirect emissions from electricity consumption), scope 3 emissions (other indirect emissions) can be very significant for buildings due to the embodied carbon associated with construction materials, in particular concrete and steel.

HS2’s approach to carbon management

HS2 Ltd has set contractual targets for all main contractors and minimising carbon is part of the project’s strategic goals and objectives. Station design teams and contractors are set a target to achieve a 50% reduction in whole-life carbon emissions against a baseline. Designers and contractors are required to adhere to the PAS 2080 Carbon Management in Infrastructure standard[7] in measuring, managing and reducing the carbon emissions in delivery for HS2.

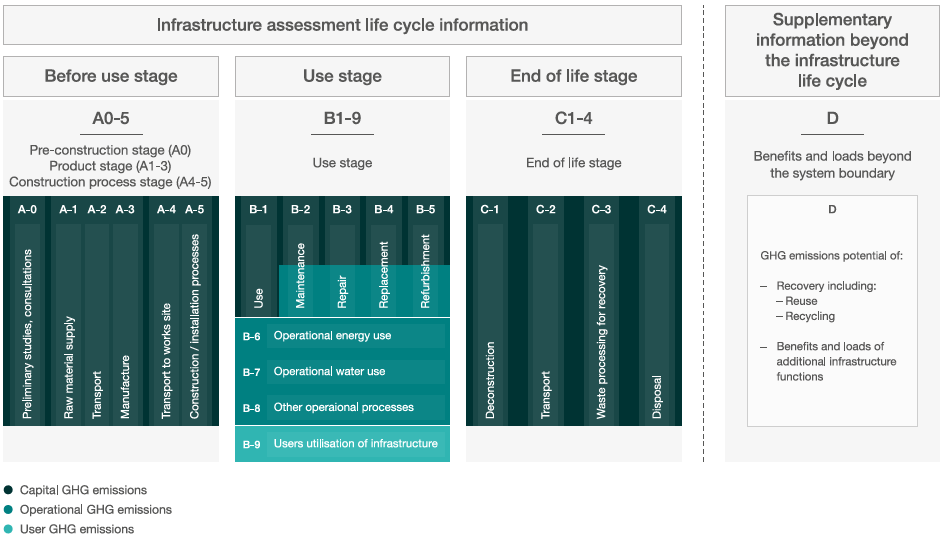

HS2 take a whole-life approach to minimising carbon emissions – particularly important with a design life of 120 years. BS EN 15978[[6]] defines life cycle modules against which GHG emissions are modelled which groups emissions into four scopes: (A) emissions associated with construction products and construction/ installation processes, (B) emissions associated with operating and maintaining the building during its life, (C) emissions associated with how the building is managed at the end of its life, for example demolition and waste disposal and (D) benefits beyond this lifecycle which may be realised from material re-use (see Figure 1).

The baseline emissions profile across HS2 Phase One stations varies between these lifecycle stages depending on the nature of the building. For example, Old Oak Common, the station in North-West London has relatively higher proportion of emissions associated with construction as this is a largely underground box structure and hence uses large quantities of concrete and steel, whereas Interchange Station, located near Birmingham International Airport, is all above ground and therefore the relative proportion of construction emissions is lower and operational emissions higher in the baseline.

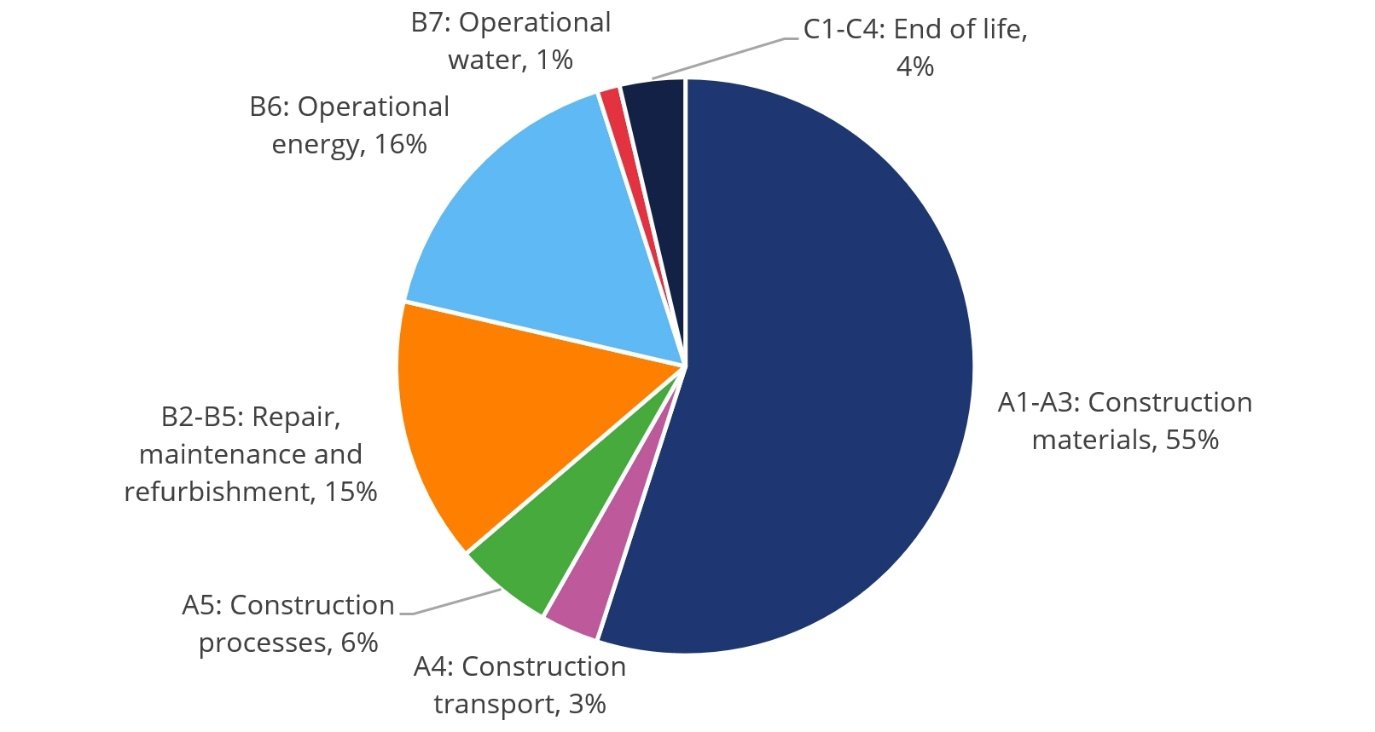

Figure 2 shows the average baseline emission profile across all Phase One stations. Generally due to the long-lived nature of these buildings and the expected decarbonisation of grid electricity over the operational life, operational emissions are lower in proportion to construction and maintenance emissions compared to a typical building[[8]].

Opportunities to minimise carbon emissions

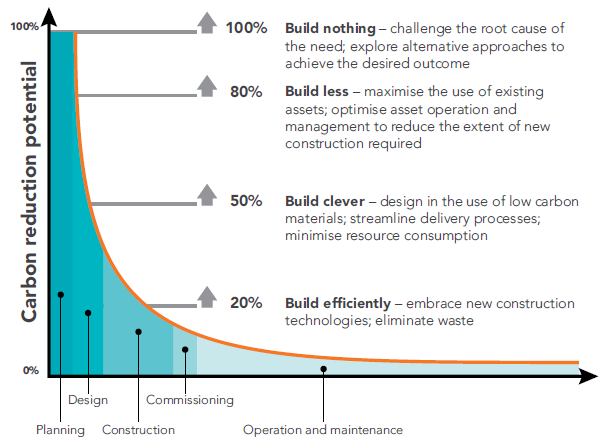

The greatest opportunities to reduce carbon emissions exist at the earliest stages of a project – indeed before a project is even defined, at the strategic planning stage. This is recognised by the Green Construction Board in their Infrastructure Carbon Review, PAS 2080 and UK Green Building Council[[9]] and summarised in Figure 3, showing the relative carbon reduction potential across the project lifecycle.

This paper will explore the various design features, technologies and processes taken by the HS2 Phase One stations during their scheme design phase and enabling works to minimise carbon emissions.

Minimising emissions at HS2 Phase One stations

Build Nothing

The greatest ability to achieve substantial carbon reduction comes at the strategic planning stage of any project, in reviewing the basic need for the project and alternative approaches to achieve the desired outcome. For HS2, this ‘build nothing’ stage is largely outside of the scope of this paper which focuses on the measures taken by the four Phase One stations to minimise carbon reductions through design and construction. However, as a major transport hub and gateway to the UK’s high-speed rail network, Phase One stations have a role to play in enabling and promoting modal shift from other transport modes, thus reducing the pressure on the existing rail network and other transport infrastructure and overall contributing to a more efficient system.

Reducing carbon is a key component of the strategic case for HS2, alongside providing greater capacity and enhanced connectivity throughout the UK. A like-for-like journey undertaken on the future HS2 network will be twice as efficient compared to conventional rail, seven times more efficient than if undertaken in a private car and 17 times more efficient when compared to aviation[11]. In addition, HS2 will free up capacity on the existing rail network to allow more freight to be shifted from road to rail.

So how do HS2 stations contribute? Whilst the project will build something the following sections describe how the design of the Phase One stations have developed in line with the objectives of HS2’s Carbon Minimisation Policy to avoid carbon where possible. This paper will explore measures taken to build less, build clever and build efficiently.

Build less

Roof Reduction and Redesign

The UKGBC define ‘build less’ as maximising the use of existing assets, optimising the asset’s operation and its management and looking at how the extent of new construction required can be reduced.

From applying the ‘build less’ concept at Curzon Street, station designers (WSP) and the architects (Grants) developed the idea to reduce and redesign the station roof. This work has meant the roof design overall has been improved, with the soffit now being changed from steel to plywood timber cassette. It is also expected these can be built in the UK, which increases the potential for carbon savings in transportation of the materials themselves. Instead of using internal ceiling panels in the Back of House area, “ceiling clouds” will be used, which will not only improve future accessibility, but reduce material and carbon impacts.

The rooflights main configuration has also been changed as part of the overall redesign and reduction (see Figure 4). This change not only makes the roof more architecturally interesting and a reduced size but also provides environmental benefits as the timber soffits will provide acoustic absorption and allow natural light to flood the building right down to platform level.

This is a great example of how a review of the design allowed the concept of ‘build less’ be a success.

Similarly, to Birmingham Curzon Street, Old Oak Common (OOC) has looked at areas where the ‘build less’ concept can be adopted as part of the overall design process.

As design for both the HS2 and the Great Western Main Line (GWML) station elements progressed it was identified that the vertical transportation elements included within the design were not required for the expected passenger demand. This led to these elements of the design being removed, however, the footprints were left in the design to allow for future proofing, if these elements were then required due to an increase in overall passenger numbers. As a direct result of this design change 2,011 tCO2e were avoided, a reduction of 0.55% from the overall station baseline[[13]].

Further design changes included the removal of the east-west beams to an underground box structure, this refinement of the design has allowed reinforced concrete beams to be omitted from the design, which has resulted in a carbon reduction of 1,157 tCO2e, or 0.32%[[14]].

There was also an allowance within the design, which had been made to cover the requirement of having a layer of concrete cover over the footprint of GWML station. The structural team refined the design proposals which resulted in the removal of this concrete layer completely. This resulted in a carbon reduction of 10,113 tCO2e, a 2.76% reduction against the baseline.

Build clever

Materials Usage – Curzon Street

The roof redesign is not the only design area that has been identified as a way of reducing the overall carbon footprint of Curzon Street Station. One of the main areas where the design could make a significant reduction is through material specification.

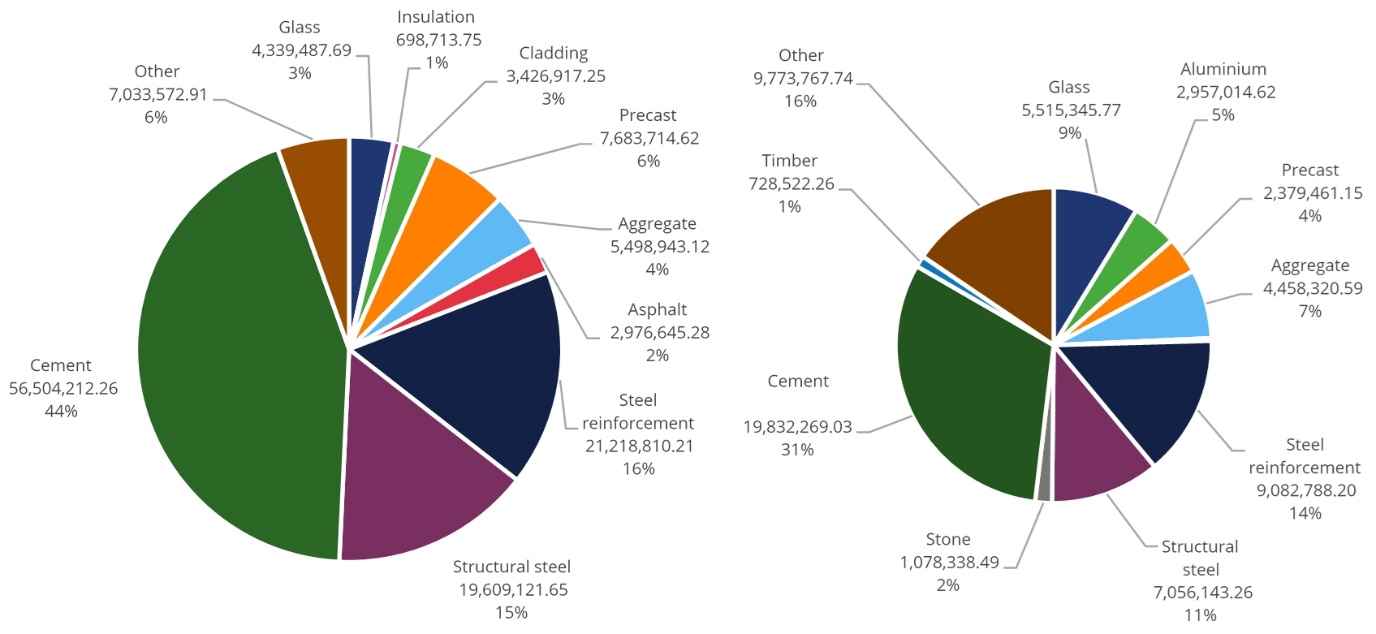

Figure 5 shows the baseline carbon hotspots for Curzon Street Station by material type, overwhelmingly dominated by cement and concrete (50%) and steel – reinforcement (16%) and structural (15%).

Through the overall design process these three key materials have been driven down by reductions in overall material quantities and using material specification as illustrated by the second chart showing the overall carbon hotspots at the end of the RIBA 3 design.

Substituting carbon intensive cement content in concrete is a well-practiced method of lowering the carbon intensity of concrete structures. The two most common alternatives are Pulverised Fly Ash (PFA) and Ground Granulated Blast Furnace Slag (GGBS), both waste biproducts from coal fired power stations and the steel industry respectively. The baseline design for the station assumed a GGBS cement replacement of 20%. In the RIBA 3 design, this percentage has increased to 66% for all structural concrete elements, including the foundation and frame resulting in a carbon saving of 28,779 tCO2e, or 16% reduction against the baseline.

For structural steel elements, the baseline assumed a 10% recycled content, this has been increased to 100% recycled content in the RIBA 3 design, realising a potential 21,738 tCO2e saving, or 12% reduction compared to the baseline. Likewise, for reinforcement steel, the recycled content specification between the baseline and RIBA3 design has been increased. Reinforcement steel commonly has a very high recycled content, as reflected in the baseline assumption of 97%, however, this has been increased to recycled content of 100%, offering a 3% reduction, or carbon saving of 6,302 tCO2e.

For these significant savings to be realised they must be included in procurement specifications and works instructions for the next stage of design and construction.

It has been identified that more work could be done to drive these figures down further if the design looks at using structural timber rather than structural concrete and steel. Although this is potentially unfeasible, as it would require a radical redesign, the opportunity has been identified and documented should the Stations Main Works Contractor choose to take it forward as part of their works once they are appointed in 2021.

Other materials such as glass and aluminium are also highlighted as an area where improvements in overall carbon reductions could be found. This would include an opportunity to reduce the total use of aluminium used within the curtain walling design and on the external envelope of the station building, by opting for a lower carbon solution such as a timber/aluminium hybrid material. Another solution would be to be appoint a supplier who uses renewable energy to produce aluminium or uses high contents of recycled materials.

The key aspect of implementing the above material efficiency opportunities is ensuring that they are integrated as part of the overall design process taken forward through the procurement, and implemented as part of the detailed design stage with the selected and appointed construction partner who will be responsible for delivering and building Curzon Street Station.

Some of the proposals may be potentially unfeasible to take forward and implement, others may require further design work to be undertaken, however it is vital that all opportunities are assessed on their own merit as well as looking continuously at other opportunities that can be developed as the station moves through its continuous development and design stages and beyond[15].

Station building redesign from hybrid Bill Design – Interchange

The Interchange Station design has undergone significant changes as it has progressed through the various design stages, this has included structural changes to the overall station building and the removal of various retaining wall structures. The main structural design change was to move the station box in its entirety from being over the trace as it was assessed and shown within the hybrid Bill, to the option which places the main station concourse to the west overlooking the Holywell Brook which is to the south-west of the site. This change, along with having the concourse entered from the north-west public plaza resulted in a carbon reduction when compared against the hybrid Bill option this equated to a reduction of 51%, or around 82,000 tCO2e over 120 years. These design changes are shown in Figure 6a and 6b[16].

There are several other opportunities that have been highlighted which are detailed in Table 1. These opportunities could be taken forward and lead to further carbon reductions as the design progresses through detailed design once a contractor is appointed.

| Opportunity | Potential impact |

|---|---|

|

Potential to increase PV generation further, to cover non-regulated energy |

Potential reduction of up to 2,680 tCO2e (5,290 reduction in B6, but increase of A1-5 of 2,610) |

|

OR use of a zero-carbon electricity tariff |

5,290 tCO2e |

|

Maximise cement replacement content to 66% in concrete design and build into specifications |

Potential further reduction of 520 tCO2e |

|

Maximise steel recycled content to 90% |

Potential further reduction of 2,518 tCO2e |

|

Use of cement replacers in the soil stabilisation process |

Use of CEMIII/A with 55% GGBS included would lead to a reduction of 4,538 tCO2e but further study needed on suitability (emission factor is 0.44 vs 0.95 kgCO2e per kg) |

|

Phasing of the car parking |

Delaying the establishment of parts of the car parks for 20 years (avoiding one replacement cycle) would save 0.34 tCO2e per space = 340 tCO2e for 1,000 spaces |

|

Logistics – Haul material by rail |

The opportunity for this remains. Potential further reduction but likely to be small (based on the 50% of materials switching to rail, ~200 tCO2e) |

|

Use of recycled plastic materials in asphalt parking surfaces |

Supplier estimate is that a reduction of 9% in the surfacing could be achieved, totalling 1,390 tCO2e |

|

Use of energy efficient equipment |

Not quantified but there are potential benefits particularly for vertical transport that can be explored at later stages |

It is estimated that if taken forward and implemented the above reductions could equate to a further 15,000 tCO2e in savings for HS2 and Interchange Station.

Value Engineering

In addition to the above areas which have been identified where carbon savings could be obtained, the overall design for Curzon Street Station has undergone a value engineering process. The value engineering process is defined as the systematic and organised approach that focuses solely on the functions of various materials and components within the design process. It directly promotes the substitution of materials for lower carbon opportunities without sacrificing the overall functionality of the design[[20]].

Through this process that was undertaken by WSP and Grimshaws in early 2019, several design options and changes were identified which would result in positive overall carbon reduction benefits if taken forward and realised. These include the removal of the 1.5 metre security strip which has been designed to be in place between platform 6 and 7. This reduces the main station building footprint overall and decreases the façade lengths, also reducing the overall entrance to the west of the station and the width of the building. In addition, the number of escalators required within the station has been reduced from 44 to 11, these have been replaced with precast concrete staircases[[21]].

Another option identified was to change the height of the roof pins and reduce the width of the station building, this in turn resulted in a reduction in the glazing requirements at the gable ends. The glazing at the western end of the station is further reduced and the eastern gable is 940m2 which is (a 6% reduction in the glazing by comparison with the baseline) and the west gable is now 800m2 which is an overall (a 20% reduction in glazing).

Through the changes to the roof pins reduction impacts were able to be made on the height of the station building on the north and south elevations, and the to the concrete columns and the mullions featured on the east and the west gables. The overall net 0.7 metre reductions to the pin heights resulted in reductions to all elements by the same amount

Most of the changes made through the value engineering process have involved overall reductions to material quantities rather than changing the material specifications themselves, this applies to all options except for the overall reductions made to escalators. Through these reductions the overall impact on the carbon footprint of the station was a reduction of 3,667 tCO2e, which is displayed in Table 2[[22]].

| VE Item | Tonnes of CO2e avoided | % reduction in overall whole-life carbon |

|---|---|---|

|

Reduction of international platform width |

672 |

0.4 |

|

Reduction of roof height, reducing extent of external walls |

38 |

0.02 |

|

Replace escalators with stairs |

933 |

0.5 |

|

Reduction of steelwork to concourse roof |

2024 |

1.2 |

Value engineering was also considered by the Interchange design team, with further changes captured as part of design development, including the following:

- Massing of the station building, and structures was greatly reduced, the station changed from two-levels to a single level podium, (saving around 7,500 tCO2e) which reduced the structural requirements allowing pad foundations to be incorporated instead of the original piled foundations (reducing substructure-related embodied emissions by around 750 tCO2e). The volume of floor areas was reduced which lead to less massing and less surface area.

- The main station building was changed to a modular design, which reduced materials and means that the station can be altered or extended as required in the future making it future proof for its 120-year life span.

- The original underground escape tunnels have been replaced by escape overbridges which means less intensive material requirements overall (around 250 tCO2e avoided).

- Material choices were reviewed for the roof elements, which resulted in glulam beams being chosen as the main structural roof elements. This reduced or eliminated the need for significant parts of the steel frame that was originally included as part of the design (avoiding around 500 tCO2e).

- Paid concourse was moved from in its position over the trace to offline which simplified the requirements needed structurally.

Further design consideration has been given to the external works, with the following changes made through the design development stage:

- Concrete retaining walls and other structures have been removed (avoiding approximately 13,500 tCO2e), changes to the car park surfacing (avoiding 24,000 tCO2e the majority being associated with fewer and lower impact replacements of car park surfacing.

- At Interchange station the assumption has been made that a 50% GGBS mix will be specified as part of the overall design, this is an overall improvement of the figure of 20% specification which is assumed as part of the station baseline figures, avoiding 1,200 tCO2e over the whole-life of the station.

- The baseline station design included several retaining structures located around the site made of concrete, the majority of these have been designed out by carefully redesigning the earthworks strategy with just a few around the trace and the station building now remaining avoiding approximately 750 tCO2e.

- Some of the design changes have resulted in a small change being needed in the amount of stabilisation required, however keeping materials on site has been given prioritisation over the option of bringing new materials into the site. There will be a surplus of approx. 89,800m3, which can be utilised elsewhere on the HS2 Project, thus promoting reuse and recycling of materials. This reduced emissions by 750 tCO2e compared to the baseline.

Through the value engineering process and as the design has progressed through the various stages of the design process, this has resulted in a reduction overall of the amount of materials needed to construct the platforms and the station building itself, which in turn has resulted in a reduction against the carbon baseline. This demonstrates how value engineering and sustainability and environment can be successfully considered together to achieve positive results.

Build and operate efficiently

Once options to optimise the design and material specification have been exhausted additional carbon savings can be achieved through the way construction is carried out. Phase One stations are still in the midst of design, however, enabling works are well underway and have demonstrated how technology can be deployed to achieve carbon efficient construction.

Low carbon construction – examples of low carbon plant from Euston enabling works

As part of HS2 enabling works at St James’ Garden’s cemetery at the Euston Station site, electric-powered excavators and track barrows have been used for the 29,000m3 of soil that has been excavated at the site (see image in Figure 4). The use of this electric plant has proven successful, not only to reduce emissions within the encapsulations structure required for these sensitive works but also improving efficiency and reducing health and safety risks due to reduced manual handling[[23]]. Further efficiencies can be gained through ensuring that this equipment, which is battery operated, is changed from a zero-carbon electricity source is similar technology is to be deployed at scale for main works.

In addition to the fully electric plant HS2 have trialled the use of a hybrid excavator at the Euston site which has enabled exhaust emissions to be cut by 88%[[24]]. The Kobelco SK210HLC-10 used on HS2 features as lithium-ion battery that stores energy recovered during slew breaking and when hydraulic oil is returned to the tank during the operation of the boom and arm functions.

A third technology used to reduce carbon emissions, as well as improve local air quality and noise impacts is hydrogen power. This has been deployed by CSJV though using TCP Ecolite TH200 Hydrogen Mobile Lighting Towers at the Euston site. Each tower can provide up to 240 hours of light and are fitted with auto dusk-to-dawn sensors to maximise efficiency. CSJV estimate that the use of the hydrogen tower lights across their contract will save nearly 100 tCO2e [[25]]. Away from the station sites CSJV have successfully trialled the use of zero emission welfare units powered by hydrogen and solar panels.

Resource efficient build

Through collaboration between the enabling and main works contractors at HS2’s Birmingham stations an opportunity was identified to reuse approximately 40,000m3 of excess spoil from the excavations at Curzon Street as required fill material for the Interchange Station site[[26]]. This not only contributes to meeting HS2’s beneficial reuse targets for excavated materials but provides carbon benefits through avoiding the need to either quarry new material at the Interchange site or purchase fill material. All material will be screened at the Curzon Street site to Class 1 material.

Design for efficient operation – Interchange

All Phase One stations are required to achieve net zero operational carbon emissions from regulated energy. The concept for station energy at Interchange Station has followed three key principles of reducing energy demand, using high efficiency technologies and using onsite renewables[[27]].

To reduce the energy demand, the station design has been developed around a passive design approach to ensure high thermal performance of the building fabric and façade reducing heat losses and gains. The orientation of the building and location of spaces based on use as been optimised to suit natural ventilation, daylighting and solar gain. Measures have included heat curtains around the door areas and natural openings in the façade to allow crossflow ventilation. Daylighting has been optimised including utilisation of north lights for the concourse area and cooling requirements have been reduced through night purging. This strategy is predicted to reduce emissions by over 20,000 tCO2e over the life of the station compared to a baseline, gas heated station.

High efficiency low carbon technologies have been utilised to meet the heating demand using air source heat pumps and use a heat recovery for the ventilation system. The building will incorporate an intelligent building management system so that building services are operated on a demand led basis. Gas as an energy source has been eliminated from the building, and combined with the other energy efficient technology included, has reduced emissions by a further 7,000 tCO2e.

A range of renewable technologies were considered for the station with solar photovoltaics emerging as the preferred option. A 2,000m2 array of solar panels to be mounted on canopies over the station car park will be installed to make the building net zero carbon for regulated energy. Mounting the PV panels on canopies enables easier and safer access for maintenance and provides shading during the day. The PV system avoids emissions of around 1,500 tCO2e over the lifetime of the station.

The combined savings associated with operational energy efficiency measures and renewables is just over 29,000 tCO2e, equating to a 38% saving over the baseline for the station building.

Rainwater harvesting – Curzon Street

In addition to the direct energy efficiency measures and renewable technologies utilised across all Phase One stations the designs have incorporated rainwater harvesting providing indirect energy savings through the avoidance of demand for treated mains water.

Rainwater harvesting system will be accommodated on the eastern concourse and the main station concourse roof. Water will be collected and fed through to a western rainwater harvesting tank, which will serve stations facilities (which includes the concourse, platforms and Back of House) on the western side, and eastern rainwater harvesting tank, to serve eastern side concourse toilets. This system will also help to positively contribute to future climate adaptation and resilience.

Conclusion

This paper has explored a number of ways in which HS2’s Phase One Stations will minimise the carbon emissions associated with their construction and operation. HS2 has set out ambitious carbon reduction targets for its buildings and the station design teams have risen to this challenge achieving very significant reductions in carbon compared to their baselines. This, along with a wide range of sustainability benefits, has already contributed to Interchange Station being the first railway station to be awarded a BREEAM ‘Outstanding’ rating at design stage certification.

The philosophy of build less, build clever and build efficiently has been used to great effect to design out both embodied carbon associated with construction and maintenance and operational carbon, to optimise designs as they develop and specify low carbon materials. Where early construction works have begun contractors have used low carbon electric and hybrid plant to further reduce their emissions.

As the four stations move from the outline design stage to detailed design and into construction with the appointment of construction partners and design and build contractors, further opportunities exist to continue minimising carbon emissions at the station sites. It will be a crucial point in the project to ensure that the design stage savings are realised though construction stage specification, procurement and requirements.

Acknowledgements

The authors would like to acknowledge the design teams from ARUP and WSP for their contributions to the content of this paper and the Phase One enabling works contractors for case studies showcasing their low carbon works to date.

References

- HM Government (2019) The Climate Change Act (2008) (2050 Target Amendment) Order 2019 ↑

- European Commission (2010) Energy performance of buildings directive ↑

- HM Treasury (2013) Infrastructure Carbon Review ↑

- Committee on Climate Change (2015) Factsheet: Buildings ↑

- BS EN 15978:2011 Sustainability of construction works. Assessment of environmental performance of buildings. Calculation method ↑

- BSI (2016) PAS 2080:2016 Carbon Management in Infrastructure ↑

- RICS (2017) Whole-life carbon assessment for the built environment, 1st edition. ↑

- UKGBC (2019) Net Zero Carbon Buildings – A framework Definition. ↑

- UKGBC (2019) Net Zero Carbon Buildings – A framework Definition. ↑

- HS2 Ltd (2019) Carbon – putting Britain on track to a net zero carbon future ↑

- Birmingham Curzon Street Station Environmental General Principles – Compliance Note – 1SN04-WSP-EV-REP-NS08-000005 ↑

- Old Oak Common Environment, Materials and Carbon Life Cycle Analysis RIBA 3 Report – 1SN04-WSP-EV-REP-NS08-000008 ↑

- Old Oak Common Carbon Management Plan – 1SN02-WSP-EV-PLN-SS07-000003 ↑

- Curzon Street Life Cycle Assessment and Carbon Baseline Report – 1SN04-WSP-EV-REP-NS08-000007 ↑

- Interchange Station Baseline Life Cycle Assessment Report – 1SN03-ARP-SU-REP-NS07-000020 ↑

- Interchange Station Life Cycle Report – 1SN03-ARP-SU-REP-NS07-000020 ↑

- LONDON-WEST MIDLANDS ENVIRONMENTAL STATEMENT – Volume 2 – Community Forum Area Report – CFA24 – Birmingham Interchange and Chelmsley Wood. ↑

- Interchange Station Baseline Life Cycle Assessment Report – 1SN03-ARP-SU-REP-NS07-000010 ↑

- Value Engineering: Definition, Meaning, and How It Works ↑

- Curzon Street – Life Cycle Assessment Design Report Environment, Materials and Carbon LCA -1SN04-WSP-EV-REP-NS08-000008 ↑

- Interchange Station Baseline Life Cycle Assessment Report – 1SN04-WSP-EV-REP-NS08-000007 ↑

- CSJV (2019) Environment Case Study: Electric Plant – Resource Efficiency ↑

- Lynch delivers first Hybrid Excavator to HS2 at Euston ↑

- CSJV (2019) Environment Case Study: Hydrogen Tower Lights – Carbon Reduction ↑

- Feasibility Study 1EW04-LMJ-PM-REP-NS08-016001 ↑

- Birmingham Interchange LCA Report ↑

Peer review

- Mark FentonClimate Change Specialist - Carbon, HS2 Ltd

- Hala LLoydLead Architect (Curzon), HS2 Ltd