Re-use of excavated materials

This paper focusses on the sustainable re-use of excavated earthworks materials and the lessons learned as part of the EKFB journey. The objective for EKFB, as the main works contractor for C2 and C3 of the HS2 route, is to maximise the re-use of materials and minimise off-site disposal. This has been achieved through the utilisation of the Definition of Waste Code of Practice (DoWCoP) managed by CL:AIRE[1], which operates a voluntary scheme for the sustainable re-use of materials, based on honesty and trust. Due to the sheer scale of the C2 and C3 sections of the HS2 project, requiring the re-use of over 30 million cubic metres of earthworks materials. The scaling up of the re-use process did initially cause concern with the Environment Agency (EA) and CL:AIRE, this document provides the approach to adhere to the DoWCoP.

Through the development of a materials management strategy (MMS)[2] and its implementation via the materials management plans (MMP), EKFB have learned key lessons that are transferable to other large-scale design and build projects with complex programmes and challenging timescales. This paper will demonstrate that the learning legacy is to engage with external stakeholders, have effective programme planning and reporting, data collection and effective sharing of information with the construction teams. Training of construction teams with direct engagement has also been key for both environmental and engineering staff.

Background and industry context

Environmental sustainability is becoming increasingly important in engineering. A key challenge is to maximise the re-use of materials on the project. The focus of this paper is related to the Main Works Civils Contract (MWCC) for the central section of High Speed Two (HS2) Phase One which includes the North Portal Chiltern Tunnels to Brackley and Brackley to South Portal of Long Itchington Wood Green Tunnel, being delivered by the EFKB Integrated Project Team (IPT).

The materials generated by EKFB excavations for this part of the project is estimated to be 35 million m³. This encompasses mostly naturally occurring material, but also smaller quantities of Made Ground, approximately 1 million m³. To re-use this material will reduce significant quantities of imported material that is needed for the project.

Made Ground is any material that has been made or affected by people. This can include artificial material, such as asphalt & concrete, but also includes reworked natural material. It is often a mixture of both, for example embankments of clay, mixed with fragments of brick and concrete.

This section of the HS2 route is associated with 58 potential contaminative land areas including landfills, disused airfields, infilled railway cuttings and embankments, sewage works, petrol stations, in filled clay pits, and quarries. It also passes through some of the UK’s most diverse/valuable/vulnerable aquifers, rivers, areas of Special Scientific Interest (SSSI), and Mineral Safeguarding Areas (MSA). Made Ground, localised hot spots of contamination, leachate and groundwater contamination are associated with the historical contaminative land uses. Contamination can include asbestos, heavy metals, hydrocarbons in soils. However, the most project critical and regulatory challenge, is the re-use of approximately 34 million m³ of natural materials that will arise from the excavation of multiple geological formations, with distinct chemical fingerprints and leaching characteristics, needing to be re-located to geologically contrasting environments, and engineered to carry the new high-speed link.

An integrated design approach has been developed to re-use excavated material (both Made Ground and natural arisings) to satisfy the fill material requirements wherever reasonably practicable, without risk to the environment. EKFB’s designer, joint venture ASC (Arcadis; COWI; Sedec), has carried out a detailed assessment of materials management at the scheme design and following detailed design stage. This enabled a significant reduction in the volume of materials that will require off-site disposal to landfill, with an aim to retain as much of this material as possible to be reused as part of the Proposed Scheme for the construction of embankments and environmental mitigation earthworks.

To assist with re-use of excavated materials the DoWCoP (Definition of Waste Code of Practice) was developed by CL:AIRE[1] (a UK charity involved with sustainable land re-use). This requires an honest and voluntary approach needing to meet four acceptance criteria:

- Protection of human health and environment – measures to protect the environment and prevent harm to human health have to be assessed and found to be adequate given the proposed use of the materials.

- Suitability of use – the material must be suitable for its intended purpose in all respects. If treatment is needed in order to make the material ready for use, the material will be waste but may cease to be waste once treated so as to be suitable for use.

- Certainty of use – the holder of the material must be able to demonstrate that the material will actually be used and that the use is not just a probability, but a certainty. Any out of specification materials which are not suitable for use will be waste.

- Quantity required – materials should only be used in the quantities necessary for that use, and no more. The use of an excessive amount of material will indicate that it is being disposed of and is waste.

This requires the design team to work alongside the Environmental and Engineering teams to consider these four criteria alongside project specific needs. Design requirements that materials can be used for are Engineering Bunds, Landscape Bunds, Noise Mitigation Bunds, creating Sympathetic Landscaping Design and other useful and interesting landscape features. Specifically, for HS2 Green Corridor[3] opportunities there are features of great benefit which will help support wildlife throughout the trace.

Approach

In order to evidence the four acceptance criteria for DoWCoP[1], several systems and processes have been put in place or developed. A few of the main examples for each criterion are described in this Approach.

1)Protection of human health and environment

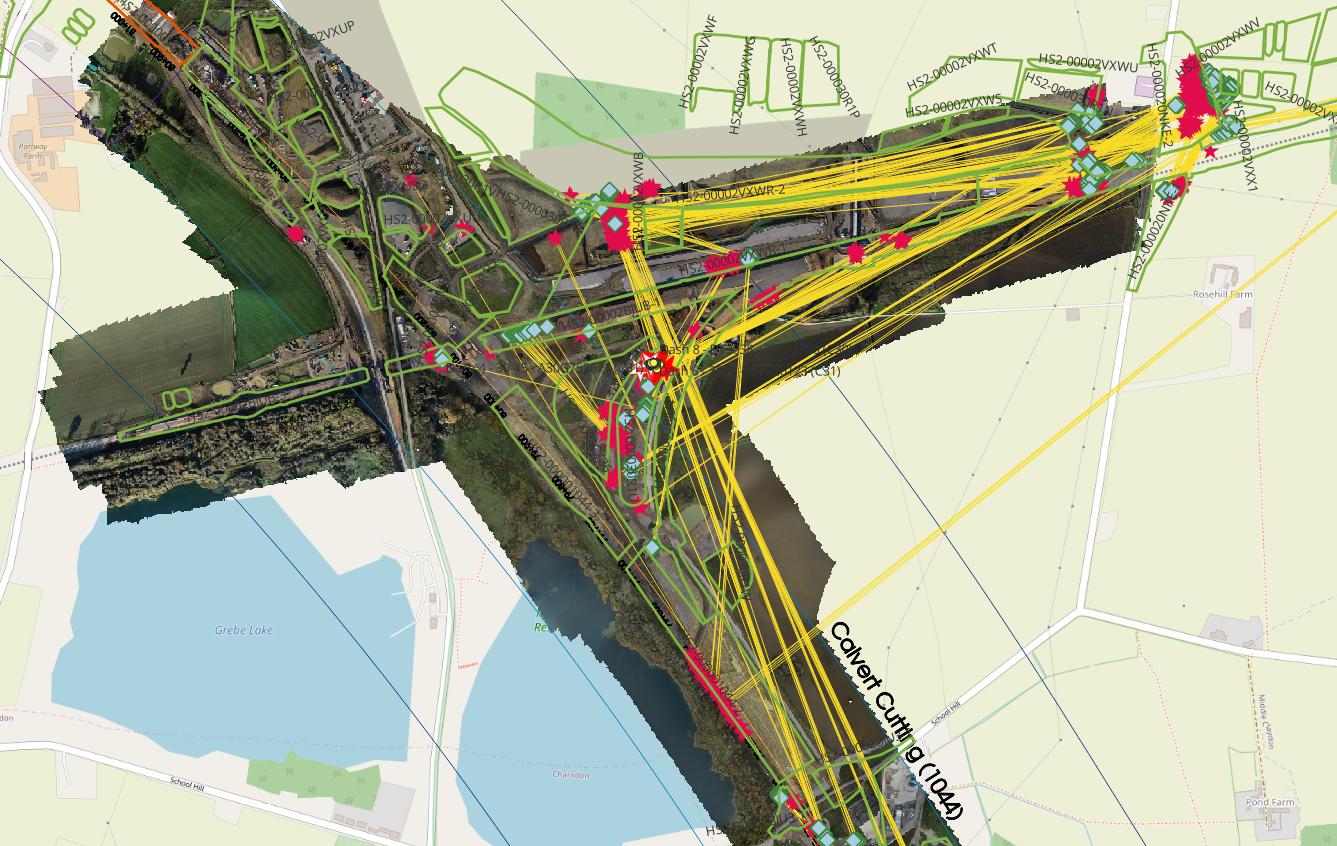

GIS

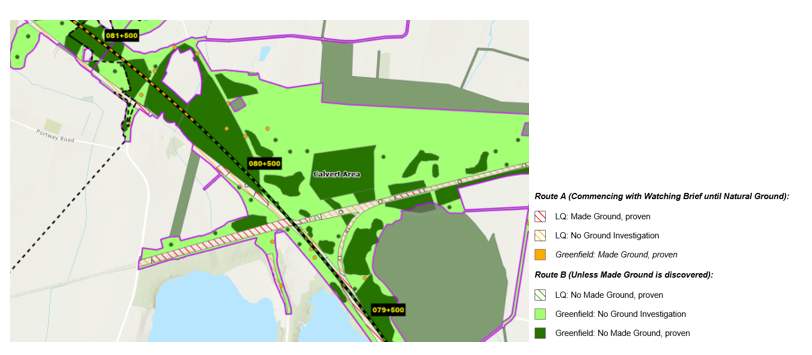

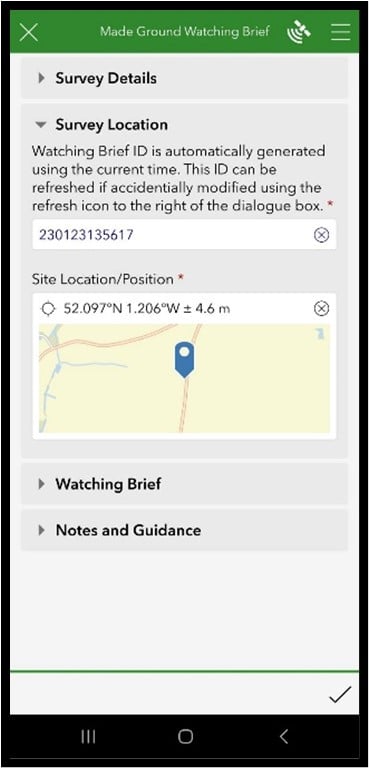

Graphical Information System (GIS) is used to ensure site teams are aware of the constraints in the areas of planned works. Layers are used to show information about local wildlife, archaeological sites and areas of Made Ground. In particular, the Made Ground GIS layer has been recently developed with the Designer to help site teams visualise the areas where further action is needed to comply with the Materials Management Plan (MMP)[2] and Remediation Strategy. If an area is identified to have Made Ground, or a higher possibility of it, actions such as Watching Briefs during excavation, additional sampling and appropriate stockpiling methodologies are applied.

Geo-environmental reports & remediation strategy

The designer has been appointed by EKFB to provide geo-environmental assessment reports and remediation strategies for potential contaminated land.

Geo-environmental reports provide an assessment of the site setting, historical land use, current uses, ground investigations within the site, ground conditions and assesses the potential risk to human health, controlled waters and infrastructure. This project does not have significant sources of contamination or areas of contaminated land as defined in Part IIA of the Environmental Protection Act[4]. Therefore, based on the site setting and historical land-uses identified in the geo-environmental reports, the remediation approach on this project comprises of a discovery strategy to assess made ground as it is excavated. This approach also allows for the identification and management of unforeseen soil contamination encountered during the works.

Engagement with Environmental Agency (EA) and local authorities

Fortnightly meetings are held with the EA regarding the management of materials. These allow information to be shared, such as MMPs, geo-environmental reports and remediation strategies. While also allowing the EA to raise any concerns, which can be taken onboard, addressed and progress provided in upcoming meetings.

Quarterly meetings are held with CL:AIRE and the EA to ensure that both parties are aware of the processes, site activities and project requirements. This enables the development of a collaborative strategic approach that is achievable.

2) Suitability of use

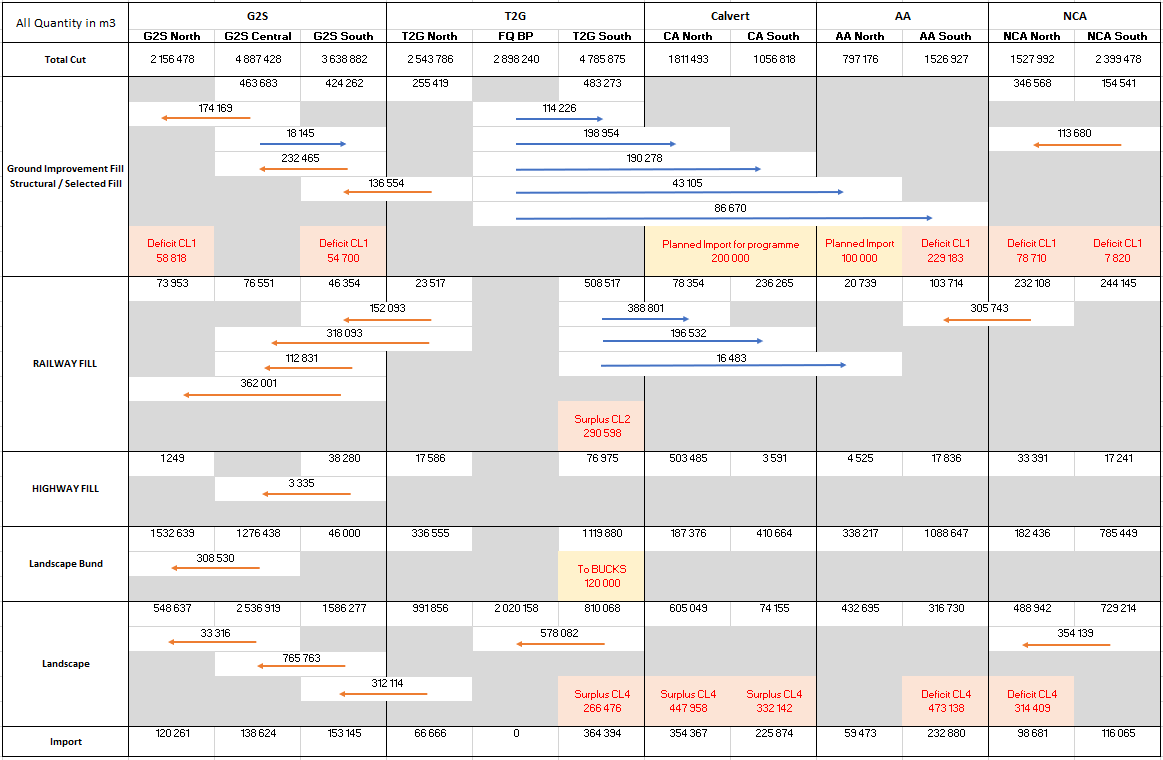

Summarised Earthworks Quality Schedules (SEQS) and Mass Haul

Summarised Earthworks Quantity Schedules (SEQS) are documents used to show the quantity and types of material in a section. When used alongside documents showing the material required in the same area, any surplus and deficit can be calculated. This is used to formulate the Mass Haul, which is a document showing the movement of material between assets aiming to maximise re-use and minimise haul distances by taking material types from an excavation area to the nearest area of reuse (see Figure 2).

Re-use criteria

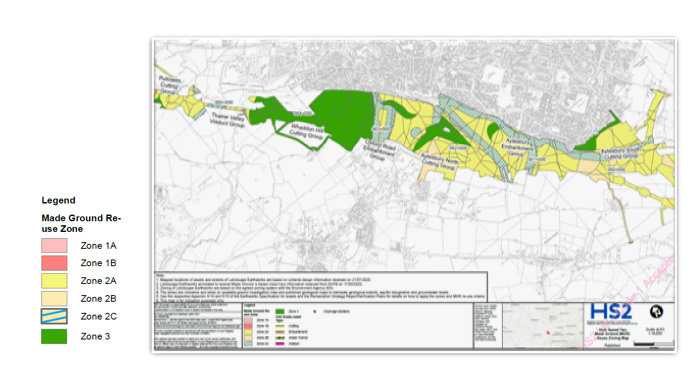

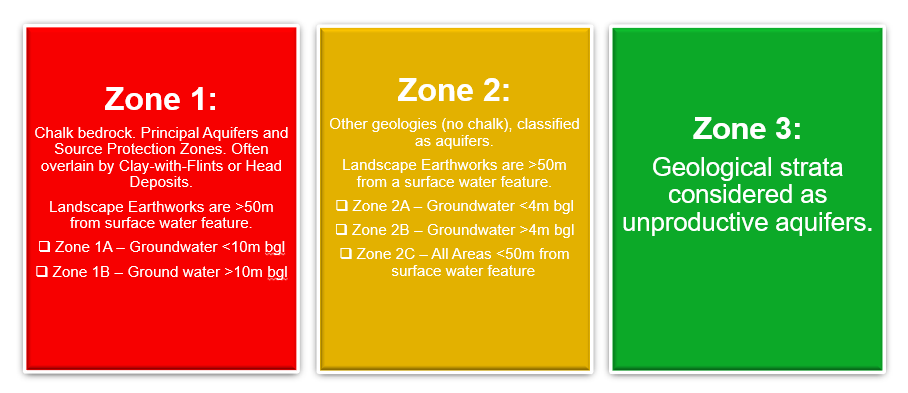

The C2–C3 section of the HS2 route crosses a number of variable geologies and aquifer designations, as defined by the EA. Given the length of the route and variation in geological strata, a zoning system has been agreed with the EA for the re-use of Made Ground. This is based on three main re-use zones that considers the protection of the environment, developed according to geology, aquifer classification, proximity to surface water and human health.

Each zone has a suite of requirements that the Made Ground material re-used must meet. Samples are tested at 1 per 1000m³ to determine which zone of re-use the material can be used in. The zones are represented in maps and GIS, an example of which is provided in Figure 3. The material is still subject to the relevant Geotechnical testing, to ensure that it has suitable engineering properties for its proposed use.

3) Certainty of use

Environmental Statement and Schedule 17 Planning Process

The environmental statement written in 2013[5] included the requirement for landscaping features such as landscape bunds to allow effective screening and noise mitigation. The effective use of landscaping bunds can reduce the height requirement of noise barriers, therefore reducing the landscape and visual impact of these structures. The landscaping bunds can increase the overall surface area for planting assisting in meeting biodiversity no net loss targets and supplement tree height that create screening. These requirements are taken forward through the design process and into High Speed Rail Act Schedule 17[6] requirements.

Under Schedule 17 of the High Speed Rail 2 Act[6] there is a requirement to engage with the local planning authorities for the landscaping design and gain consent, whereby the soft landscape design is agreed. The landscaping design isn’t limited to the planting and seeding requirements but also the landform such as noise bunds, landscape screening bunds and shaping of earthworks sympathetic to the surrounding environment. The soft landscaping design isn’t ridged but flows to allow integration into the landscape, particularly important in areas of outstanding natural beauty.

Gaining the Schedule 17 consent provides certainty in terms of the design requirements that is also driven by the undertaking and assurances commitments for stakeholders such as local landowners, Natural England (NE), and the National Trust (NT). This combination of requirements ensures that the certainty of use requirements is understood, evidenced, and met.

The materials required for the construction of the landscaping design is detailed via the Model Production and Delivery Table (MPDT)[7]. This provides information to the team on the ground regarding the design requirement for the construction of earthworks such as embankments and cuttings including materials required for soft landscaping features.

The placement of landscaping bunds is considered good practice in terms of environmental design and provides an opportunity for sustainable design.

4) Quantity required

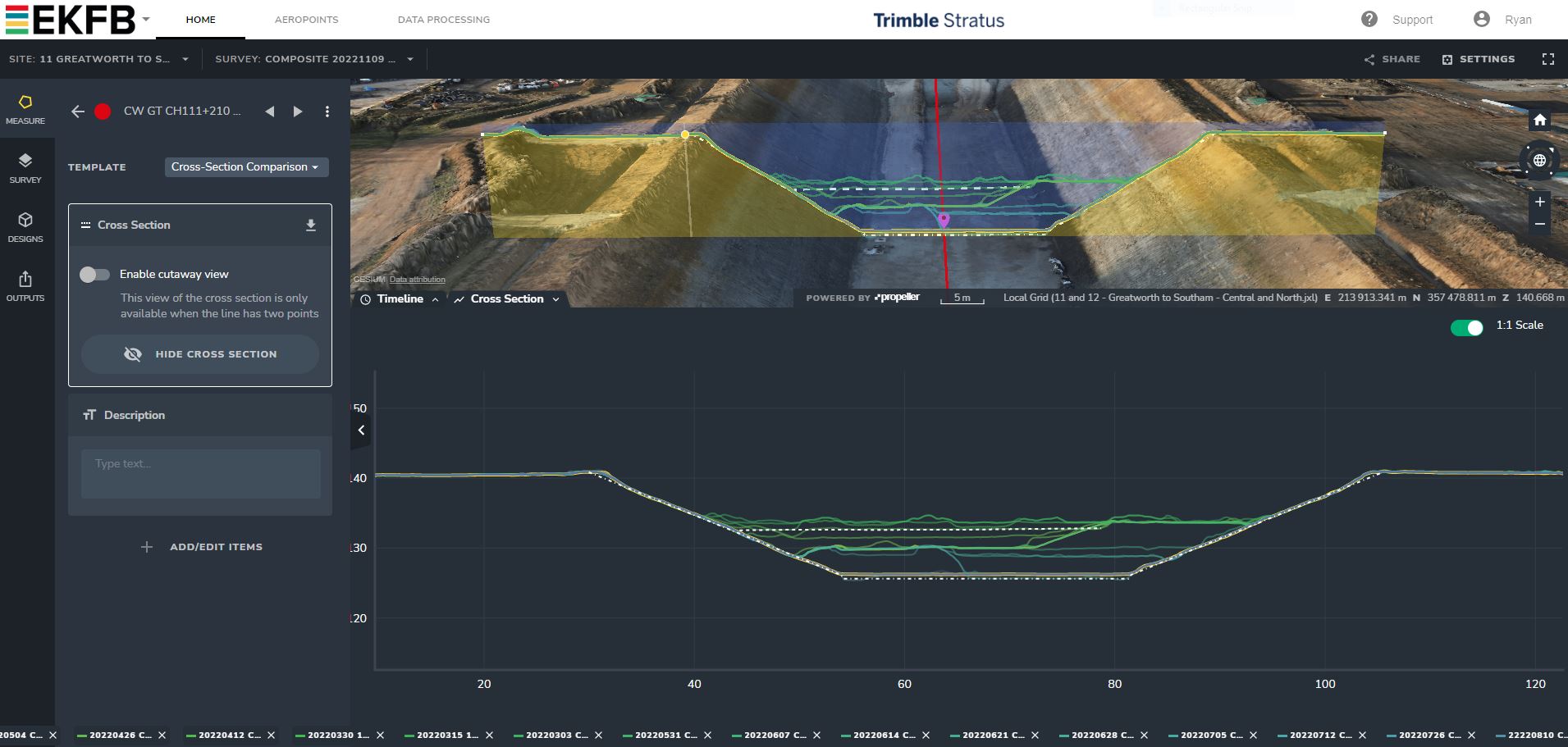

DIGGER and propeller

It is critical that material re-use solutions can be practically implemented. The DIGGER (Digital Graphical Earthworks Reporting) tracking system is a key, comprehensive, live and automated material tracking system which monitors excavated material movements from the place of origin to the final destination, including treatment and testing/characterisation to demonstrate suitability for re-use. The system uses various data streams from GPS cloud-based Trimble tracking on excavators and trucks, to drone surveys creating a digital 3D model of the earthworks (Figure 5). This tracking system is key to both demonstrating compliance with the DoWCoP and indeed satisfying regulators. It also aims to ensure that vehicles are fully loaded, to lessen the carbon footprint of the project.

DIGGER helps to ensure the requirements of DoWCoP are satisfied by showing that the materials have been used in quantities that are necessary and not in excess. It also allows the users to see if the machines are being used effectively and help reduce machine idle times which provides the data needed to improve efficiencies and measure carbon impacts.

Weekly monitoring of the onsite excavation and fill operations are captured, recorded, and measured using drone technology and visualised via software provided by Propeller, example in Figure 6. This can be viewed against the current design models to monitor progress.

Improvement opportunities and outcomes

Improvement Opportunities and Outcomes

As the project continues, there are many opportunities to refine the process and improve the management of materials. Some of the improvements from the work detailed in the Approach section above have been deduced and even used for further development and innovations. The outcome of these improvements is described as follows:

GIS

As discussed within the approach, GIS is used for ensuring site teams are aware of the constraints in the areas of planned works and inform if actions such as watching briefs during excavation, sampling requirements and stockpiling locations.

To ensure the gathering of the correct information for the validation of these requirements, forms have been developed via the ArcGIS Survey123 App. Users can input the information whilst out in the field and have the points of data shown on GIS, which can then be expanded to create reports (Figure 7).

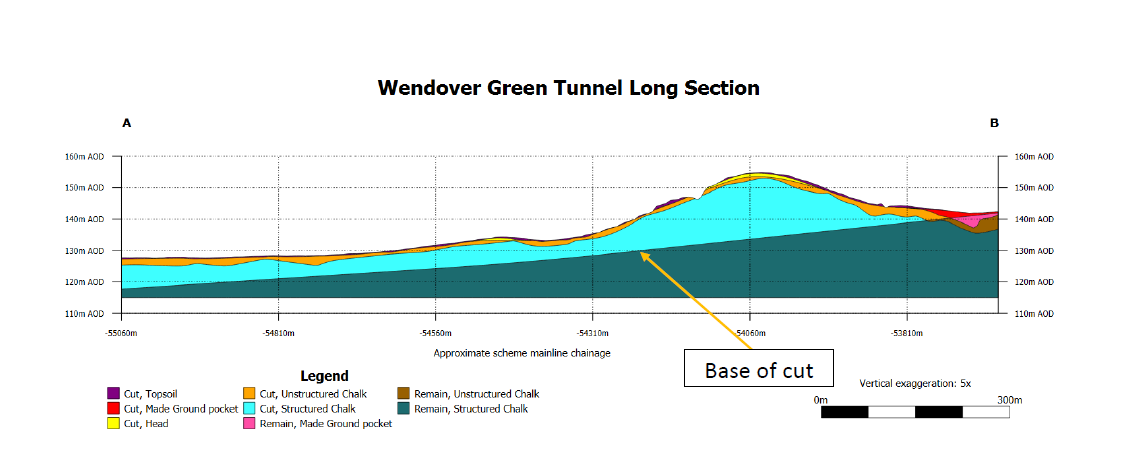

SEQS and Mass Haul leapfrog analysis

To assess the accuracy in the SEQS used for the Mass Haul, the designer was requested to provide additional support in undertaking suitable material assessments and provide the volumes of each material classification anticipated within key earthwork cuttings. The assessments were undertaken by importing the available data into Leapfrog software. An example of one for the figures for Wendover Green Tunnel is seen in Figure 8.

Engagement with Environmental Agency and stakeholders – DoWCoP

CL:AIRE and the EA had initial concerns on the EKFB proposed approach of a single MMP[2] with up front declaration for the total volume of Route B natural material with annual verifications. Following discussion with both parties a phased approach to the Route B MMP was proposed and accepted whereby the annual declaration is based on works commencing during the next year. The approach for the Route A made ground materials was based on the geographical division of the project, with a single submission.

Lessons learned and recommendations

Some key lessons learned, and recommendations have been found through the development of the Approach to follow the DoWCoP framework, these include stakeholder engagement, reporting and internal communication.

Engagement with Environmental Agency and other stakeholders

Whilst the engagements with the local authorities and EA started early in the project, due to design development and delivery constraints engagement admittedly wasn’t consistent. The key lesson learned here was to ensure that the EA were taken along the journey ensuring that regular engagement sessions remained in place. Where there were limited updates available, an explanation should have been provided to the EA to assist in their understanding of specific project constraints, there are often many mechanisms in place in the background that can leave a perception to external stakeholders that the project is at a standstill.

A stakeholder engagement plan needs to be developed at an early stage that clearly sets out the terms of the objective of each engagement process, to include the meeting arrangements and objectives. This gives the contractor the ability to reduce the instances of unintentional dis-engagement and to keep meetings on track and to schedule.

Quarterly meetings with CL:AIRE and the EA have been of benefit and have been running since September 2022. This has allowed EKFB to engage with the regulator and the owner of the DoWCoP document, CL:AIRE, to discuss the parameters of the MMPs and the required reporting strategy. Stakeholder engagement site visits have also been organised to give the EA and CL:AIRE the opportunity to see a large-scale earthworks project and to engage with the practicalities and complexities in the management of high-volume earthworks. EKFB shall be offering further visits to stakeholders in the coming earthworks season to continue pro-active engagement and promoting an open and honest communication strategy. With hindsight this dual engagement approach should have been completed earlier in the project.

Reporting turnaround time

Management of reporting requires careful and considered management as delays can cause an adverse chain reaction that can negatively impact on the construction programme. There are several supporting documents required for the submission of a MMP, which include geo-environmental reports, remediation strategy documents and the verification plan. MMPs are the documents submitted to CL:AIRE specified within the DoWCoP that allows the re-use of excavated materials. Therefore, delays to the collation and production of these documents will cause the MMPs to be delayed with a knock-on impact on the construction programme by not allowing the re-use of material until these are produced and submitted.

Delays cannot always be avoided; however, improved management of information and resource planning can provide a more robust reporting programme to avoid impacts on construction.

Distribution to site teams

Site teams are made aware when there are new documentation and procedures to follow, included in the MMPs and supporting documents via the document control process. However, as part of the roll out, EKFB supported site teams by running project section specific briefing sessions to get the details and key points across. This allowed for the tailoring of relevant information for each team and for the site teams to voice any questions or concerns. It also linked the project section to a suitable key contact for further correspondence on this subject.

A general presentation was provided and recorded for a technical training meeting delivered to the wider team. This presentation formed part of the technical library that is available to people working on the project.

Sustainability

The minimisation of imported materials supports HS2 in delivering their Carbon Policy Aim (E27 Paper)[8]; ‘minimise the carbon footprint of HS2 as far as practicable and deliver low carbon long distance journeys that are supported by low carbon energy’. The assessment of carbon is ongoing and completed on an annual basis. However, the re-use of materials rather than import of virgin aggregates are significantly more efficient, including where there is a requirement to use lime stabilisation to improve geo-technical properties of the materials.

Based on last year’s figures for earthworks re-use of 25.6 million tonnes this is a reduction of 2.5 million road journeys. The reporting due for February 2024 will provide more accurate figures of cost savings, however indications of carbon reduction is positive.

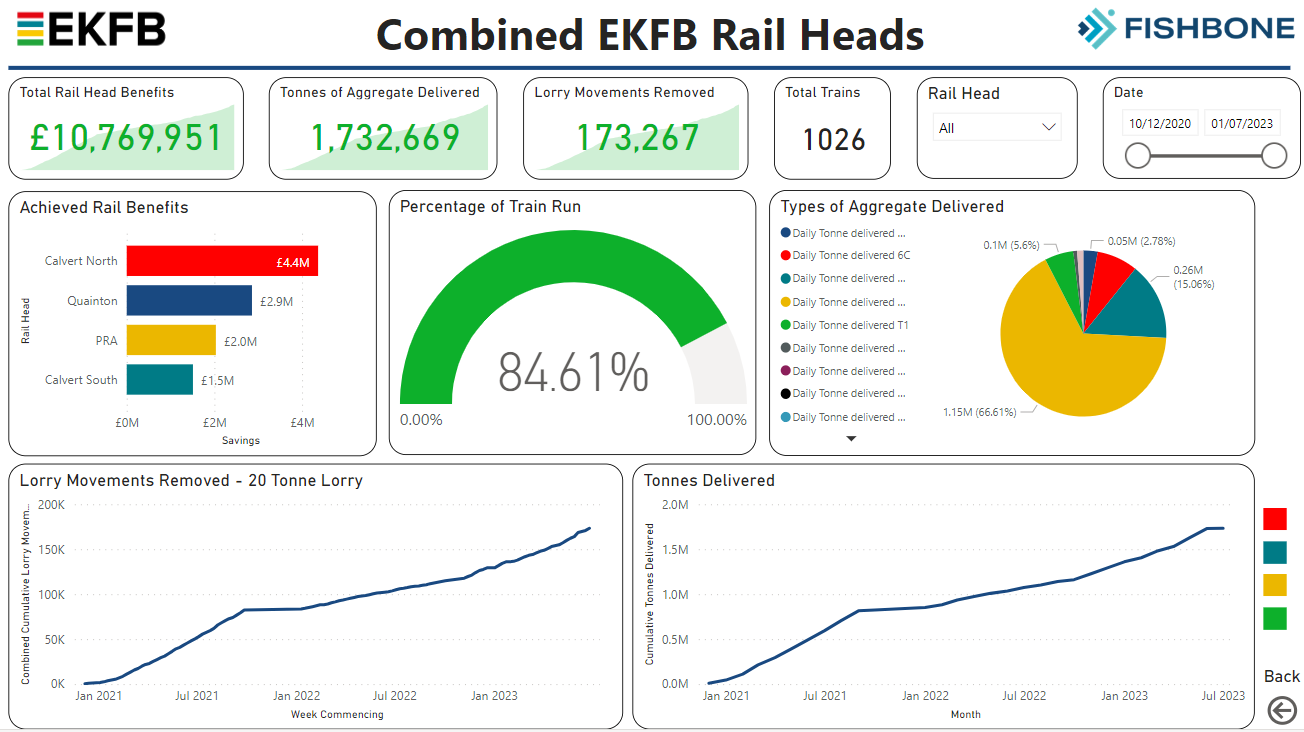

Transportation of materials using the existing railheads has also provided a reduction in the number of lorry movement and consequently a significant carbon reduction. The graphic presented in Figure 9 details the cost benefit of delivering aggregates via the rail heads and the reduction in lorry movements.

Conclusion

Although much of the excavation and re-use of materials is ongoing, learning and recommendations have already been found from the work and procedures described in this learning legacy document. The key point throughout is that early and consistent engagement and communication with all parties is vital to project success.

The EA, Local Authorities & CL:AIRE have been critical to the success of this process. Their input in stakeholder engagement sessions has allowed for the update and improvement of the design and procedural aspects that aid the reduction of environmental impact of the HS2 project. Communication and management of the reporting process and timescales are important to avoiding delay to site works. Finally, discussions with the site delivery teams are also key to ensure the procedures are understood and implemented correctly, while allowing for any queries to be responded to.

Key learning legacy outcomes are as follows:

- Early and consistent engagement with external stakeholders

- Reporting – effective programme planning of reporting deliverables

- Data management – utilising electronic systems for the management of information and to assist in close-out reporting

- Presentations and discussions with site delivery teams to complement the introduction of new documentation and procedures

Acknowledgements

ASC Land Quality Team

EKFB Earthworks Team

EKFB Environmental Design Coordinators

Environment Agency – incl. Katie Baker & Matt Wales

HS2 – incl. Steve Box & Paul Lippitt

Independent Advisor – Ged Duckworth

Route B – MMP Procedure where Made Ground is not expected

SEQS – Summarised Earthworks Quantity Schedules

References

- CL:AIRE – The Definition of Waste: Development Industry Code of Practice Accessed on 25 May 2023.

- EKFB- Materials Management Plan Strategy

- High Speed Two Ltd – HS2 Green Corridor . Accessed 28 July 2023.

- legislation.gov.uk – Part IIA of the Environmental Protection Act 1990. Accessed 28 July 2023

- High Speed Two Ltd – HS2 Phase One Environmental Statement: documents . Accessed 28 July 2023.

- Department for Transport – High Speed Rail Act 2017 Schedule 17. Accessed 28 July 2023.

- Model Production and Delivery Table

- Carbon Policy Aim (E27 Paper)

Peer review

- Lorna Byrne