Redesigning the management of hazardous noise – enhancing worker hearing health

High Speed Two (HS2) aims to reduce occupational ill-health throughout the life of the project which includes the protection of hearing health. Passive hearing protection aids are traditionally used on construction sites to reduce the impact of noise on the workforce however these have been found to offer low protection. As part of its innovation programme, HS2 partnered with a London-based SME – Eave – to develop their cutting-edge hearing protection technology for people working in the construction industry. The trial was funded by HS2, Innovate UK and the Department for Transport (DfT), via First of a Kind (FOAK) competition.

The Eave hearing protection technology works through ear defenders gathering noise level data at in-ear level and uploading the data by bluetooth to localised beacons to a smart hub enabling unplanned noise hazard exposure to be identified and mitigated.

The Area South Enabling Works Contract (EWC) was selected as a testbed site to trial this technology. This shared learning provides an overview of the 12-month initiative, the outcomes of which led to the EWC contractor rolling out a new in-noise mandate across the whole EWC project. The in-noise mandate required all contractors whose workers were exposed to hazardous noise from 80db +, to procure and implement the use of an active only hearing protection with monitoring solution. The EAVE Focus lite headset and accompanying peak platform – digital software solution used throughout the 12-month initiative formed the solution technological specification and requirement detailed within the mandate instruction.

There were three main outcomes: increased level of assurance in The Control of Noise at Work Regulations 2005; a better understanding in effectiveness of traditional health protection mitigation; and evidence of differing health protection behaviours.

Background and industry context

The industry traditionally manages the impact of noise and the protection of worker hearing health with the issue of personal protective equipment (PPE), in the form of passive hearing protection, namely the wearing of foam ear plugs. The HSE [1] reports that ‘compressible foam earplugs are generally poorly fitted, as users are generally unaware of how these should be compressed before fitting, or unaware of the importance of correct compression’. CSjv examined the ‘fit’ of foam ear plugs, using the 3M ear-fit technology, it found that 70% of those tested on first fit had no protection. This additional factor was significant in promoting the benefit of trialling the use of the new technology.

The Eave solution used a digitally enabled headset, EAVE focus lite, that both protects hearing and gathers noise data. The data is transferred to unique noise mapping software and analysed to produce accurate information about every worker’s noise exposure across the worksite. The smart technology both locates and measures noise to enable a targeted approach to protect every person’s hearing across a construction site. Eave headsets are designed with revolutionary ‘hear-through’ technology that eliminates the need for a site worker to remove them to hear. Hear-Through technology allows a safe level of sound to be heard through the headset, enabling face-to-face communication. Operatives no longer need to decide between protecting their ears and hearing their environment. Eave’s Ear Defenders will automatically adjust the levels of protection to suit the ambient noise in the environment.

Over 46 million people in Europe work in harmful levels of noise, according to the HSE [1]. Occupations most at risk of harmful levels of noise exposure include construction. Construction and electrical processing have rates which are more than double the average. The higher the level of noise, and the longer individuals are exposed to it, the greater the risk they have of suffering harm from it.

Hearing damage can occur when the level of noise a person is exposed to is over 80dB(A). Eight hours of workplace noise exposure at 85dB(A) is the legal limit of noise ‘dose’ in the UK, as defined in the 2005 Control of Noise at Work regulations.

If the noise level is higher than 85dB(A) then the legal limit will be reached in a shorter period. For each 3dB increase in noise level, half the exposure time is allowable. For example, four hours of noise exposure at 88dB(A) and two hours at 91dB(A) are considered equivalent, in terms of noise exposure dose, to eight hours at 85dB(A).

Hearing loss caused by work is preventable [2] but once hearing has gone it won’t come back. Exposure to high noise levels can cause permanent hearing damage, often without the sufferer being aware of it until it is too late. It can lead to tinnitus (ringing in the ears) or deafness. The Health and Safety Executive (HSE) estimate that more than 2 million people in Great Britain exposed to unacceptable levels of noise at work.

Department of Work & Pension (DWP) statistics for 2015-16 (the latest available) show that of the top 10 occupational diseases by employer liability insurance claims (24,114), occupational deafness made up 68% of all claims. Health & Safety Executive 2014 figures show that £360m was spent on hearing damage claims in the UK that year [3]

First of a Kind (FOAK), Department for Transport and HS2 funded a trial of the Eave hearing protection technology to prove the concept and raise standards.

Trial of Hearing Protection Technology on the Enabling Works Contract

The Enabling Works Contract (EWC) on the southern section (Area South) is part of High Speed Two (HS2) phase one which includes demolition of buildings within the wider Euston area, utility diversions, environmental and ecological monitoring and a programme of historic environment and archaeological activities, delivered by the Costain Skansja joint venture (CSjv).

The Area South EWC was selected as the testbed site to perfect the latest version of hearing protection technology.

The CSjv objective was to use the innovation to understand levels of exposure, to improve behaviours and attitudes toward hazardous noise and to reduce noise at source, or to redesign the working environment to reduce exposure where possible on their enabling works contract. 5 sites, 8 subcontractors and over 100 operatives were involved from groundworks, temporary works, demolition, and utilities.

The trail content was explained in an Hs2 CSJV Eave video

Trial Outcomes

Eave data insight enabled CSjv to reconsider the hierarchy of controls to assess how redesign or reduction could be achieved from the overexposure highlighted.

The insight alerted the contract to focus on areas of over-exposure and breach of the 2005 Control of Noise at Work regulations.

Noise hazard incidents were identified from the noise mapping functionality that had been overlooked on the initial Risk Assessment and Method Statement (RAMS). These areas included jet wash, hot works burner and basement working which generated unplanned noise hazard.

Behavioural difference within compliance toward the wearing of Eave headsets and attitude toward hearing conservation.

Using the technology to map the noise on the EWC

The Ear Defenders gather noise level data and note the time and beacon they are closest to. When plugged in or in range, the headsets will upload the noise level data to the Smart Hub. The Smart Hub then transfers the data to the Cloud via the Internet, where it appears on the Peak platform. Peak illustrates the noise data as a series of interactive graphs and noise maps, accessible via computer.

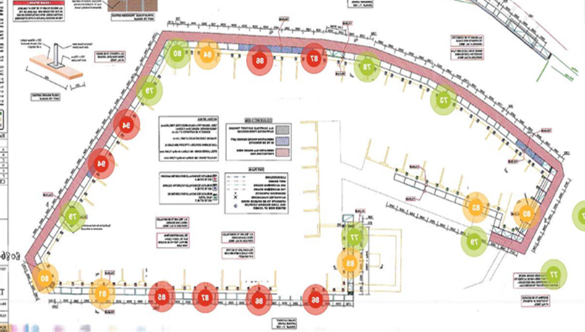

The sensors used by the Eave hearing conservation system are bluetooth location beacons. These beacons cover a 10 m2 radius, although if there is a significant amount of metal interference onsite, you may choose to place them closer together.

Each beacon periodically transmits it’s unique ID number over Bluetooth, which the Eave FocusLite headsets can see. The headset then logs the number of the closest beacon with every noise level measurement. To populate the heatmap, the noise level readings that are logged against each beacon are averaged to give a noise level at each beacon location.

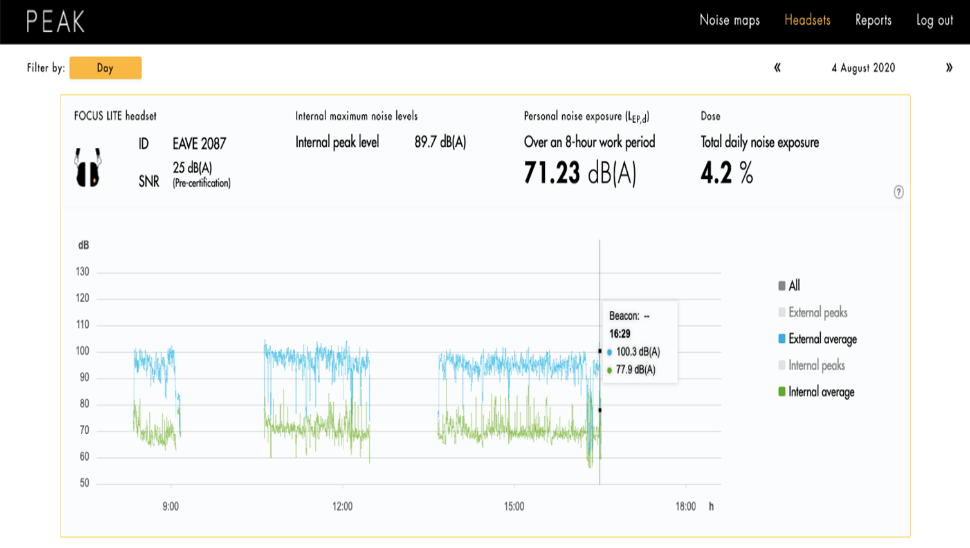

The Eave Peak platform allowed CSjv to view the noise levels operatives, and working groups were exposed to across multiple sites, this is shown above, where the Red, Amber, Green coding represents noise risk. The visualisation map, provided real-time, pin- point noise exposure, hot spot locations on a work site to further investigate. It was through this functionality that unplanned noise hazard exposure was identified. These hazards were not considered within the initial RAMS, the raised awareness from positioning the beacon locator, and compliant wearer use of the headset gathered data, lead to the RAMS being reviewed, and attention placed to relocate the workers and reduced from high to low hazard risk. These areas and activity of work included operating a jet wash, undertaking hot works, noise emitted from the burner and a clearance gang working with the basement of a building under demolition.

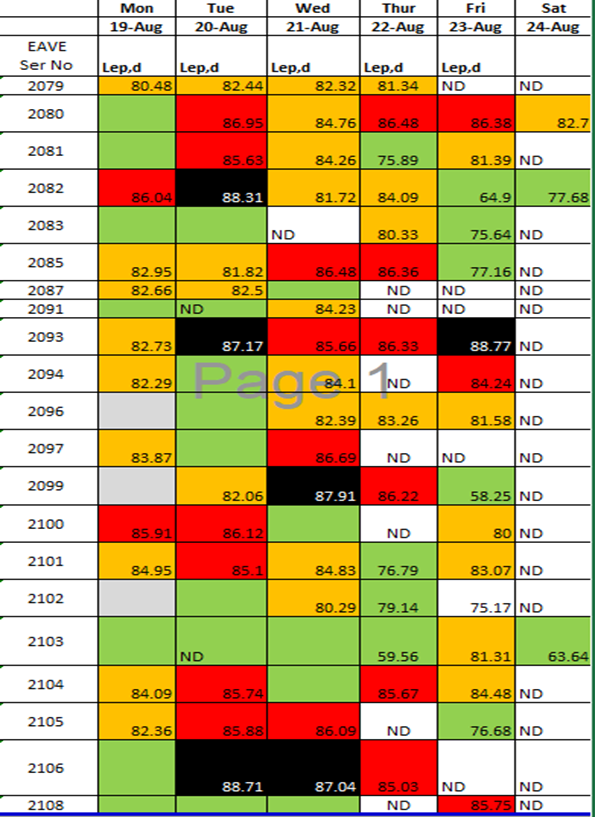

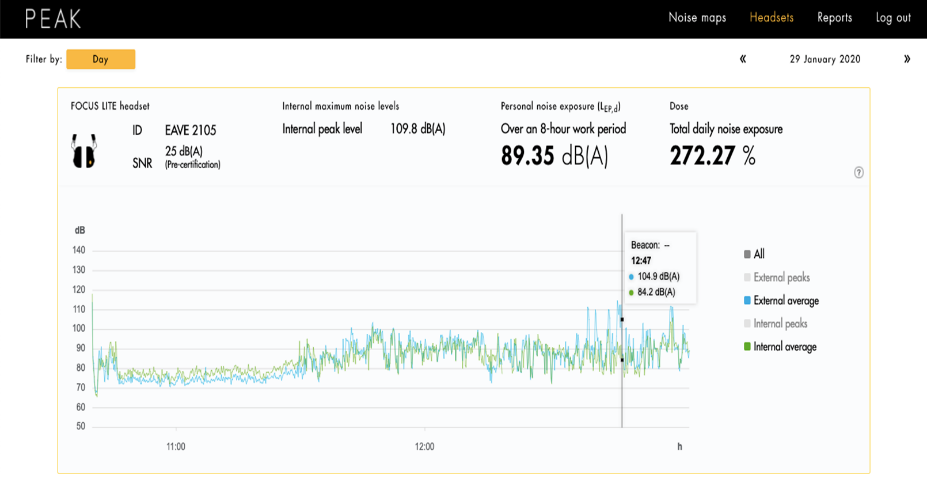

CSjv were able to create a chart to pin-point individual over-exposure and breach of the 2005 Control of Noise at Work regulations. These are shown below and highlighted within the black coding.

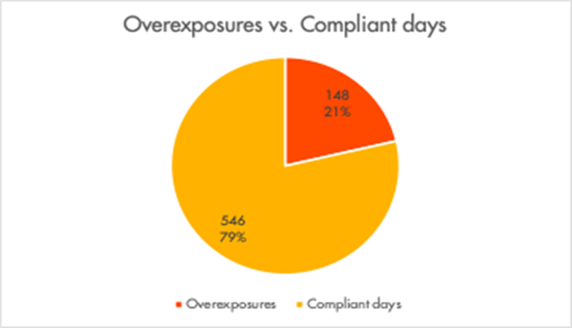

Figure 4 includes all headsets that have been active for at least 3 hours per day. In the example given that there was a total of 694 days considered to be active which equated to 7000 hours’ worth of data. From the 694 days there were 148 overexposures. Key takeaway: 20% of the active days (3 hours min operation), operatives were overexposing themselves to noise which led to 148 incidents of overexposures. The raw data provided a comprehensive overview of individual noise exposure at the level of the ear.

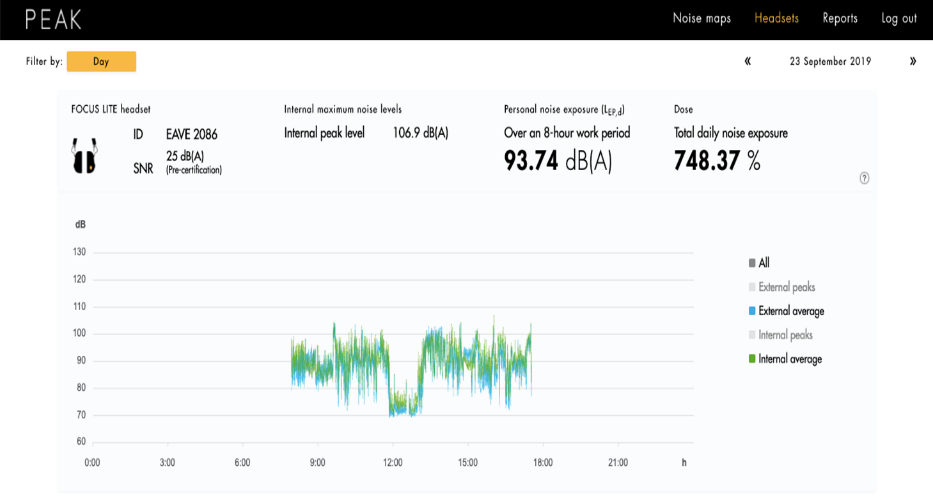

Figures 5-9 below are snapshots of the system. Figures 5-7 are examples of the individual exposure rate (3 behaviour types) noncompliance, perceived compliance, and full compliance.

Note: no separation between external and internal measurement – therefore no protection was afforded to the worker and exposure reaching over 90dB in the working shift.

Note: wearer decides when to apply the headset protection, at a point at which perceived hazardous exposure would be experienced – in fact the snapshot of data displays the external exposure reached 109.4 d B.

Note: The data insight evidences that the operative had no exposure to hazardous noise on the day that this data represents, and that a 25 db protection was afforded from compliance with the protection solution. This evidence will support HS2 within its aspiration toward reducing the incidents of occupational ill-health throughout the life span of the HS2 infrastructure project, by evidencing the elimination of personal harm.

Note: Data insight displays specific external exposure and identification of headset in use within the location, the assessment of the data can identify risk, and action.

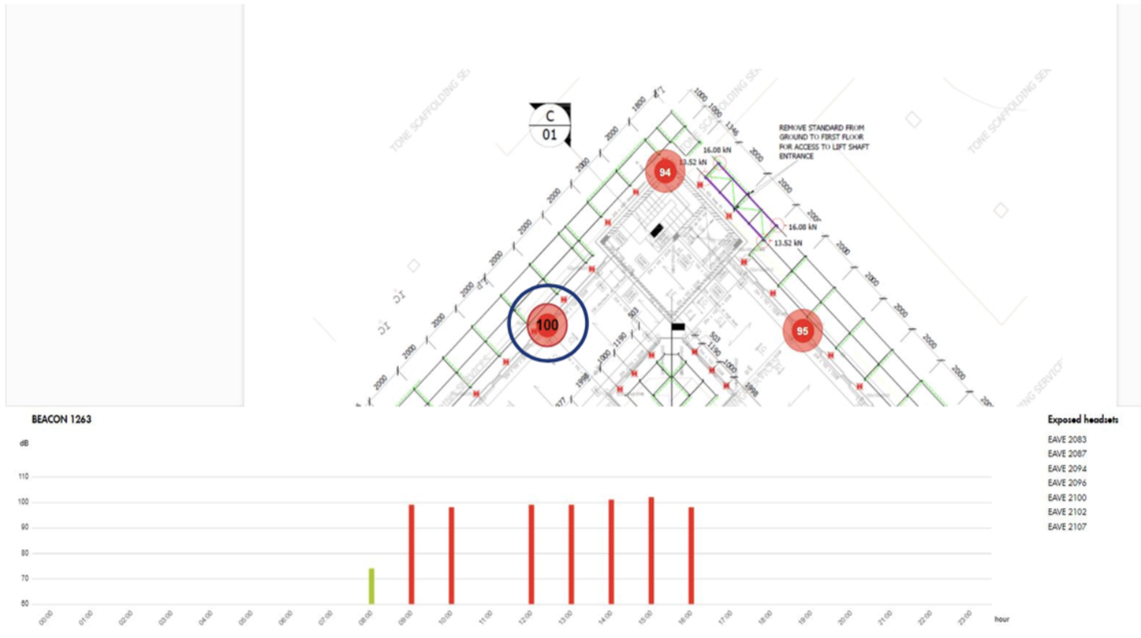

Note: provision of regular reporting enabled CSjv and its supply-chain contractors to improve understanding, of exposure, operative compliance and pin-pointed action required to raise standards and hearing health impact.

Note: figure 10 demonstrates the ineffectiveness of the fit of the compressed foam earplugs used prior to the introduction of the Eave technology. 70% of operatives tested had no protection on first fit testing.

CSjv used the Eave solution and digital platform to gain insight into external and internal noise exposure, to understand the extent of the hazard, the actual protection achieved and to explore how the technology could inform redesign of hazard, or workforce at source. The initiative reached across a selection of the EWC scopes of work, including demolition, ground works, temporary works and utilities contract companies. An outcome of the trial was to mandate the use of the AOHP-M technology across our EWC works.

Recommendations

It is recommended that all organisations review their current methods of managing noise and hazardous exposure, to establish if effective and efficient. To incorporate the CSjv mandate approach to introduce AOHP-M as a standard of hearing protection and monitoring.

Acknowledgements

The author wishes to thank all those who had contributed to the successful implementation of this innovation with special thanks to Mark Goodenough H+S manager of McGee, Jay Williams H+S manager (then Costain) and EAVE contract manager Omar Al-Dabbagh for their tiresome commitment to achieve this outcome.

References

[1] Real world use and performance of hearing protection

[2] Workers are still going deaf and yet its entirely preventable

[3] Reference for NIHL is the number one occupational disease by claims