Reducing impact to local residents during foundations removal

The Regent’s Park Estate demolitions were located on the approach to Euston Station, in a particularly sensitive residential area, placing the works under very high scrutiny from the client, public and local authority. This paper details the foundations removal and efforts to reduce the noise and vibration impact on residents. A combination of a drill and burst methodology was used alongside a traditional breaking method with limits set on where the traditional excavator and breaker methodology was used, depending on proximity to receptors. Although drill and burst is a workable solution, it is an expensive and time-consuming solution. It is only recommended to use this type of solution where no alternative to use machines can be found.

Background and industry content

The Enabling Works Contract (EWC) on the southern section (Area South) is part of High Speed Two (HS2) phase one which includes demolition of buildings within the wider Euston area, utility diversions, environmental and ecological monitoring and a programme of historic environment and archaeological activities, delivered by the Costain Skansja joint venture (CSjv).

Possession of Regent’s Park Estate in the London Borough of Camden (Figure 1) took place in February 2019, and the site consisted of 6 buildings:

- Ainsdale

- Old Tenants Hall

- Eskdale

- Silverdale

- Granby House

- Stalbridge House

The buildings were demolished via a combination of long reach off-plan demolition using non-percussive techniques, and floor-by-floor using percussive techniques.

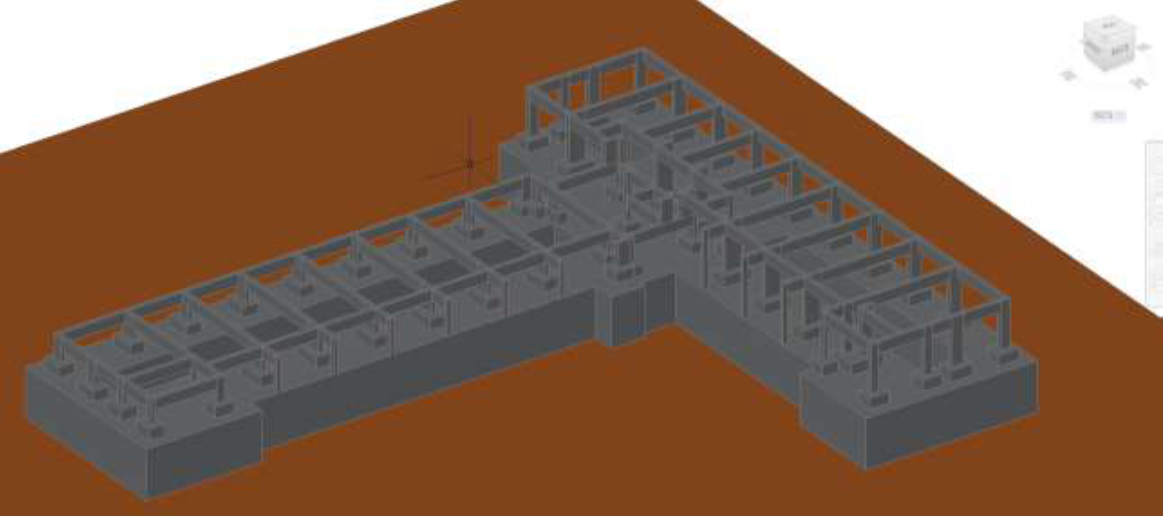

Once demolition of the superstructure was complete, the focus turned to the 5-metre-thick foundation pads (Figure 2) with Eskdale (3) and Silverdale (4). The removal of these foundation pads was made more difficult given the proximity of the closest active residential building which sat less than 2 metres away, at the closest point to the pads. Consequently, there was a risk of significant noise and vibration effects arising from the works.

It was imperative that the impact to the neighbouring residential buildings was minimised. There were a number of challenges from London Borough of Camden, who quite rightly wanted to ensure best practical endeavours were undertaken to ensure minimal impact of the works on the local community.

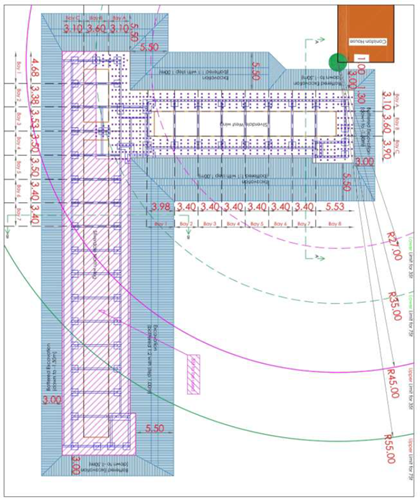

The EWC team carried out noise modelling (Figure 3) and set parameters for working to ensure the noise and vibration limits were not breached. For Silverdale (building 4 in figure 1), the closest point of the adjacent building, Coniston House, was used as the marker. From the modelling it was identified that it was not possible to use a 35-tonne machine and a breaker within 27 metres of this point without exceeding noise and vibration limits. However, due to the concrete strength and size of the concrete pad foundations, anything smaller than a 35-tonne machine would severely limit the ability to be productive, so an alternative needed to be found.

Alternative solution

Collaboration between CSjv and Clifford Devlin Ltd produced a combination of a drill and burst methodology, alongside the more traditional breaking method as set out in Figure 3. Limits were set on where the traditional excavator and breaker methodology was used, depending on proximity to receptors. For the remaining areas, the team used drill and burst to minimise the impact and of noise and vibration.

Vibration predictions were produced based on historic measured data, the results of which were used to divide the worksite into risk zones, defining the chosen methodology. The underlying principle being that the criterion defining significant noise and vibration effects would not be exceeded, and that impacts would otherwise be reduced as far as reasonably practicable in accordance with the principles of Best Practicable Means (BPM)[1].

Lessons learned

During the operation, the noise and vibration models were found to be over-cautious and, using live data as we progressed, allowed us to extend the use of the machine and breaker. Drill and bursting is time consuming and expensive, and reducing this down to the minimum is important to maintain operational efficiency.

Ensuring that the core drilling is to full depth is important. The supplier of the drilling and bursting tried to cut depths short to save on costs and programme, which meant that we were not able to break the foundations as required and needed a return visit. This led to working in a deeper excavation than planned. Tight control and proof of the coring depth is important.

Clearing at least one free face around the foundation is important so that under the pressure of the expanding chemicals (or crackers), there is space to move the foundations in to.

Having a free edge also needs to be controlled from a working at height perspective, there is the ability to clear this side post-coring and just as the chemicals are inserted.

If not removing whole foundations, this will again create leading edges as you leave part-foundations in place, requiring edge protection to be installed and frequently moved.

An unexpected beneficial use was identified alongside UKPN assets that were delayed in being removed. Where there were restrictions on vibration, damage was prevented to known poor jointing and poor conditioned electric cables.

Recommendations

This is a workable solution in areas where noise and vibration is a concern, however it is still an extremely expensive and time-consuming solution. It is only recommended to use this type of solution where no alternative to use machines can be found.

Acknowledgements

- CSjv Euston Approaches Demolitions Team: Dan Brown, Era Shah, Joe Jelfs, George Horsley, Hanna Toorabally, Ricky Prett, Andy Evans

- HS2: Martin Oates, Neil Bishop, Andreas Michael

- Clifford Devlin: Dean Rylands, Sebastian Kiszkis

References

[1] Environmental Protection Act 1990, Part III Statutory Nuisances and Clean Air, 1990