Environmental management: supply chain engagement

The Enabling Works Contract (EWC) on the northern section of High Speed Two (HS2) Phase One is delivered by the Laing O’Rourke Murphy joint venture (LMJV).

LMJV is a contract management organisation (CMO) that manages the delivery of work by its supply chain. The contract is structured by almost 100 separate work packages that are “mini projects” with individual LMJV project managers, supporting teams and specific subcontractors delivering the work. Many of the subcontractors are small to medium enterprises (SMEs) that often do not have full-time environmental resources to support and advise on the very high standards of environmental management required by HS2.

LMJV has implemented a range of tools to communicate and support the supply chain in delivering environmental requirements, including a formal training course specially designed for and supply chain construction managers and supervisors, endorsed by the Institute of Environmental Management and Assessment (IEMA), the professional body for environmental management.

This paper describes how these tools have been employed to upskill the supply chain in environmental management, how the approach can be transferred to other parent company projects and to share with HS2 and their contractors.

Background and industry context

The HS2 Phase One enabling works contracts (EWC) are contracted under NEC option F.[1]

This paper focuses on the Enabling Works Contract (EWC) on the northern section of High Speed Two (HS2) Phase One delivered by the Laing O’Rourke Murphy joint venture (LMJV).

This is a management contract in which LMJV is the management contractor and the works are delivered by around 100 work packages by a range of subcontractors.

Many of the subcontractors are small to medium enterprises (SMEs) that are highly specialist, niche services, including specialist ecology and landscape management suppliers. These subcontractors may not have developed environmental management systems (EMS) or the skills, knowledge and competence to manage the very high environmental standards imposed by HS2 Environmental Minimum Requirements (EMR). However, where best practice and innovation was evident, it was recognised that a platform to share and showcase this was required.

Approach

It was identified early in the project that the supply chain delivering the work was, in many cases, not sufficiently knowledgeable or competent in environmental management to ensure compliance with HS2 Environmental Minimum Requirements (EMR). This was evidenced in the tendering process, by the findings of site inspections and in the environmental incidents reported. Policy commitments were therefore set, including objectives and targets for the upskilling of the supply chain and sharing and awarding best practice in the LMJV Environmental Sustainability Strategy.

Strategy commitments were implemented by a range of engagement, awareness and training tools as detailed below.

LMJV and Supply Chain Construction Manager and Supervisor Environmental Training

A study of environmental site findings and incidents revealed that the root cause of over one third environmental incidents reported were due to limited knowledge and understanding of environmental processes by site supervisors.

Therefore a formal training course was devised and delivered specially designed for construction managers and supervisors entitled “Environmental Sustainability for Construction Sites”. The course has been approved by the Institute of Environmental Management and Assessment (IEMA)[2], the professional body for environmental management that represents continued professional development (CDP) and upskilling. This is a one-day training course delivered by the LMJV environment team to provide the knowledge and tools to control and monitor site environmental impacts. The course includes an introduction to environmental sustainability, risk and opportunity, compliance and the key design and site environmental topics from resource efficiency to archaeology and heritage. Environmental training bespoke to HS2 requirements and aimed at supervisors and construction managers has never previously been delivered by LMJV’s parent companies or other HS2 contractors.

The course is unique in that it is targeted at those responsible for delivering work on site and those supervising operatives at the “coal face”. The material has been developed for this audience in line with the CIRIA Environmental Good Practice on Site pocket book (CIRIA 2016)[3] and is supported by Supply Chain Sustainability School [4]videos. LMJV’s parent companies and HS2 are corporate members of the School, and have recognised that this is an underutilised free resource to help upskill the supply chain and its workforce. Interactive training activities are included to engage the audience, especially those who learn better with kinaesthetic training (a learning style where individuals prefer interactive methods of training to understand their roles and responsibilities effectively). This includes hands-on sessions where participants are involved in experiments to highlight carbon emissions, oil spills and noise.

The feedback from this training has been extremely positive with 100% of those that attended the training stating that the course had achieved its objective. Feedback comments include: “Very informative course and I have gained a lot of knowledge I didn’t have, great course and trainers, brilliant insightful course that gives you a look behind the scenes of what LMJV have to do and deal with”. This is further evidenced by the engagement of construction managers and supervisors with the environment team, checking and verifying actions and obtaining further information. There has also been a marked decrease of 55% in environmental incidents between the period July to November 2020 and July to November 2021 (when the training was introduced).

Ecological Clerk of Works (EcoW) Forums

The ECOW fora were created as LMJV and its ecology supply chain had a significant number of complex ecological constraints and licence requirements to deliver and comply with. The ECOW forum was created to allow the ecology supply chain to fully understand license requirements, HS2 standards and the processes in place including license competency, readiness review, documentation, setting to work, communication, record keeping and reinforcement of ecological requirements.

The ECOW fora have upskilled the ecology supply chain and provided clear communication on managing ecological requirements on the project. The result has been considerably less ecology-license-related incidents and more engaged ecological support in the field.

Supply Chain Environmental Forum and Webinars

The quarterly supply chain environmental forum invites supply chain representatives to share information and learning on project progress, key issues and opportunities to:

- Identify opportunities for efficiencies and best practise to meet HS2 standards

- Communication of environmental updates

- Raise awareness and upskill with regards to environmental management

- Network

- Produce best practice case studies

- Celebrate and communicate success

An additional function is the provision of webinars to the supply chain on current topics. To date sessions have been delivered on carbon management, circular economy and avoiding site materials becoming waste to increase supply chain engagement in key environmental sustainability issues.

The Golden Newt Awards

The supply chain has been encouraged to engage in a positive environmental culture through the Golden Newt awards. This provides an opportunity for the subcontractors to be recognised for environmental best practice and innovation. Case studies are welcome to anyone working within the supply chain, covering any environmental topic from archaeology and air quality to ecology and designing out waste.

Winning case studies are chosen by the senior leadership team (SLT) and awards are presented at the Supply Chain Forum to the successful subcontractor. An example of a Golden Newt winning case study was a solar-powered owl surveillance camera innovation that enabled surveillance of a owls in their nest to monitor progress so that works could continue once the chicks had fully fledged without any disturbance to the owls. This technology has been shared with the whole supply chain as a legacy piece should further constraints be experienced on HS2.

The Cleaner Construction Showcase

The Cleaner Construction event was held on 18 May 2021 to showcase innovative low-carbon and resource-efficient products to HS2, LMJV and its supply chain and encourage trials and procurement. Displays included electric, battery and hybrid operated plant and machinery, sustainable materials and SMART building operating systems. This showcase was the first on the HS2 project and the exhibited the benefits of moving to low-carbon site solutions including reduction in carbon emissions and other greenhouse gases, air pollutants, noise, reduction in the cost of fuel and SMART data. It was a high profile event that included attendance by the HS2 Transport Minister.

Environmental alerts

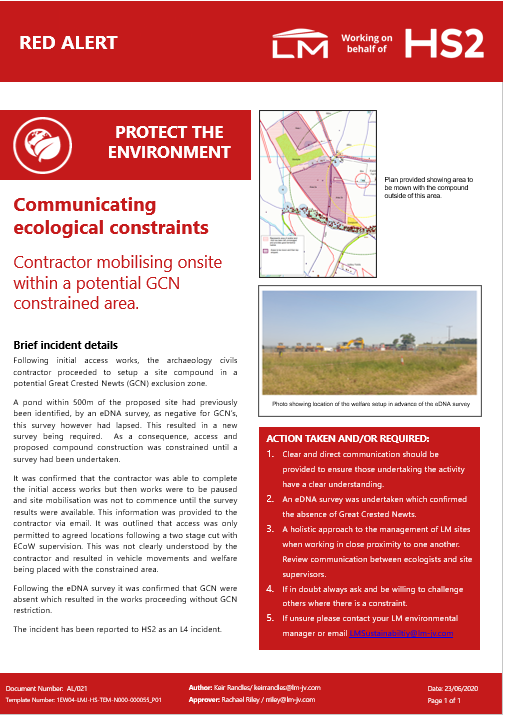

Environmental alerts are a key communication tool to inform the supply chain on environmental management. Alerts include:

- Red alerts to inform where an environmental incident has occurred and for sites to check that they have the correct controls in place to avoid further incidents

- Amber alerts to inform on topical or seasonal environmental issues

- Green alerts to provide guidance and advice on environmental topics

- Blue alerts to inform on lessons learnt and further environmental controls as a consequence of environmental events.

Environmental newsletters

The monthly Environmental Newsletter is sent out within LMJV and the supply chain and provides information on environmental performance, risks and control of impacts and opportunities. It provides details on the Supply Chain Forum and webinars, shared learning, best practise and case studies. This links into the sustainability section of the LMJV Hub – a Sharepoint library of key information for the supply chain.

Supply Chain Directors’ Forums

Supply chain directors’ forums are held regularly and managed by the Procurement Lead to provide project updates on milestones achieved and upcoming works. Any sustainability updates are presented by the Environmental Lead and provides an opportunity to announce the Golden Newt Award winners.

Outcomes and learning

The training, awareness and communications tools mentioned above have been developed in line with the project’s environmental impacts and opportunities, being responsive to the issues found during compliance assurance and incidents and responding to the upskilling needs in the supply chain.

These tools have been extremely successful evidenced by the marked decrease of 55% in environmental incidents between the period July to November 2020 and July to November 2021 (when the training was introduced). However, it would have been of more benefit to have them in place at the start of contract when the supply chain was mobilised. The focus at that time was on delivering the works to programme and this over-looked essential proactive steps to upskill the workforce and improve communication of environmental requirements that would have improved environmental compliance and avoided some of the initial environmental incidents. The key lesson learnt is to implement this early on in new projects for HS2 and LM’s parent companies to establish an adequately skilled workforce.

Notwithstanding this, there is now in place an upskilled supply chain in terms of environmental sustainability and this provides a positive environmental culture with the project that can be continued within the project and across the construction industry. The Supervisor and Construction Manager training course is a crucial upskilling requirement to ensure effective environmental performance.

Learning legacy

The tools, knowledge and competence provided has resulted in an engaged and collaborative supply chain that understand the complex and high standard of HS2 environmental requirements. The legacy left by LMJV on EWC North has been to reduce environmental non-compliance and incidents and it has provided an upskilled and engaged workforce (particularly to SMEs) with a competence recognised by IEMA that will be available going forward to HS2 and other clients delivering large-scale construction projects.

Recommendations

Early on-boarding of the supply chain is paramount to ensure that they are aware of the environmental requirements on the project. This is to be followed by clear instruction and the provision of tools, forums to guide, coach and support subcontractors in the delivery of work in line with environmental requirements.

It is important that any training is implemented early in the project and that it continues to be rolled-out during the project. A clear communication of information to the supply chain is key. Using regular alerts to guide and instruct, and to encourage a positive culture with continued best practice. Acknowledgement and recognition of the good work being delivered is also important to encourage further innovation and collaboration.

Conclusion

Provision of a range of tools and forums to the supply chain to manage HS2 environmental requirements has been a success for LMJV, although not provided as early on in the project as required. The Construction Manager/Supervisor Environmental training has been key as environmental requirements are briefed to site operatives and the first point where compliance is determined. A high level of engagement has been achieved through the design of the course being targeted at this specific level. Continued sharing of knowledge and best practice through the Supply Chain Environmental Forum and contributing case studies to the Golden Newt Award has driven the subcontractors to continually improve and gain recognition and the awards.

Acknowledgements

Rachael Riley, LMJV Sustainability Lead

Sally Grewcock, LMJV Senior Environment Manager

Matt Wisdom, Ecology Lead

References

[1] Option F is a cost reimbursable management contract where the financial risk is taken largely by the client. NEC Contracts . Accessed 9/12/21

[2] Institute of Environmental Management and Assessment (IEMA) “ Environmental Good Practice Guides 2016”. Accessed 9/12/21

[3] Construction Industry Research and Information Association (CIRIA). Accessed 9/12/21

[4] Supply Chain Sustainability School (SCSS). Accessed 9/12/21