Improvements for the design and operation of demolition hanging screens and curtains

Following the extensive use of demolition curtains on the Costain Skanska joint venture (CSjv) High Speed Two (HS2) Enabling Works Contract (EWC) South, a guidance document has been produced with the aim of highlighting risk elements, passing on learning and design considerations, and improving the safe system of work employed for this operation. Currently, no guidance documents have been published for the use of demolition curtains by any organisation.

This document covers technical design and safe operation of demolition curtains. In summary, wind speeds should be constantly monitored, defining a set time after gusts for velocities to settle. The design should consider the risk of accidental loading from demolition debris. Exclusion zones should also be assessed during the design stage, specifically for the crane holding the curtain.

This would be of use to any project undertaking extensive demolition works. It provides valuable learning from extensive use of the demolition curtain, which is currently an area with limited guidance available

Background and industry context

This guidance has been derived from the learning associated with the works to deliver the Enabling Works Contract (EWC) on the southern section of High Speed Two (HS2) phase one, which includes demolition of buildings within the wider Euston area, utility diversions, environmental and ecological monitoring and a programme of historic environment and archaeological activities, delivered by the Costain Skanska joint venture (CSjv).

This good practice document is in lieu of specific guidance from the National Federation of Demolition Contractors (NFDC), or any industry best practice information regarding the use of hanging demolition curtains. It consolidates methods and lessons learnt from HS2 EWC South which could be considered during the development of methodology and design when planning and undertaking demolition works with the use of hanging demolition curtains. This guidance document follows on from the HS2 Learning Legacy paper ‘An alternative approach to demolition screens at Regent’s Park Estate’

During the Euston Power Signal Box (PSB) demolition project, a series of improvements were made from the standard way of working described in the original paper. A key improvement was the introduction of retaining concrete barriers eliminating accidental loading on the base of the curtain during demolition.

This guidance and its recommendations should not be quoted as a specification for the intended works. It is intended to be used by suitably qualified and experienced persons for consideration. The reality of site and environmental conditions should always be considered alongside any guidance. It is strongly suggested the reasoning is written down as part of the site-specific risk assessment.

The areas dealt with specifically cover: the effects of wind; accidental loading from debris; and exclusion zones. These were key aspects that had to be considered when delivering the EWC contract and it is valuable learning to share with the industry. Each area is detailed in the sections that follow.

1. Effects of wind on hanging demolition curtains

1.1 Managing wind during lifting

Wind is a consideration at all times when utilising a demolition curtain. The curtain will have a large surface area to weight ratio which wind will act against. This could potentially put excessive lateral forces on the crane boom, causing structural failure or collapse. As well as excessive lateral forces on the crane, the high area to weight ratio will also make the curtain difficult to handle and control for both the operator and slinger.

Things to consider in any design and planning:

- Design of curtain should include maximum permissible wind speed and the crane manufacturer should be consulted.

- How wind speed is monitored and managed, including who is responsible for monitoring.

- Cranes must be fitted with an anemometer on the crane tip, providing wind speed measurements to the operator.

1.2 Cranes

Cranes should be fitted with anemometer on the crane tip and a second independent handheld/remote anemometer can be used if required, measuring wind speeds at the maximum curtain height. However, both wind speeds must be assessed before lifting the curtain.

When the curtain is hung, the building will provide a block to the wind. Only the minimum curtain surface area should be exposed to the side or above the building, to reduce the potential for wind loading. However, the maximum exposed surface area during the demolition sequence should be assessed within the design, to assess the crane wind speed limit. The assessed condition must be controlled and not exceeded.

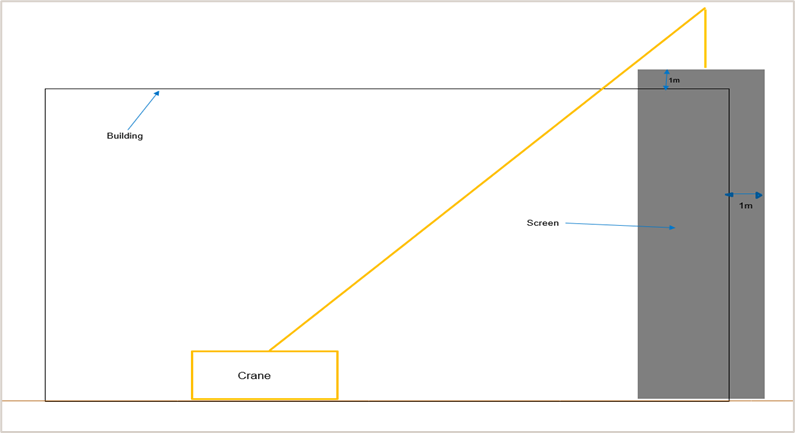

Where possible, the total surface area of the curtain should be assessed for wind loading. If the wind blows in the opposite direction, towards the exposed side, the curtain will be sufficiently close to the building elevation to allow any wind loads to be transferred into the structure rather than the crane jib. This is seen as a nominal 1m (see Figure 1). It is recommended to assess the prevailing wind direction and prioritise the location of the curtain. In any location, ensure that the maximum wind speed is not exceeded.

1.3 Recommencement of work following a wind event

To recommence works following an excessive wind event, it is recommended that the forecast is checked and the following conducted before recommencing lifting.

- If forecast is lower than permissible wind speed: 15-minute period of no wind gusts above permissible wind speed to be witnessed.

- If forecast higher than permissible wind speed: one-hour period of no wind gusts above permissible wind speed to be witnessed.

1.4 Example lesson – wind effect when moving a demolition curtain

In one instance, while moving the curtain, the crane team lifted the curtain to relocate. At this point, it was completely exposed, and a strong gust caught the curtain and blew the curtain outside of the exclusion zone, exerting lateral loading on the crane and boom. This was a high potential incident.

During the moving of the curtain, which had to be lifted at full height to pick the tail end off the ground, the curtain was slewed away from the building and therefore greatly exposed. The site-specific risk assessment covered in detail the lifting and lowering when it was to be used for demolition, but did not cover general moving around site.

It is recommended that the curtain is only lifted within permissible winds speeds, and with only the specified surface area exposed. For storage and movement, it is recommended to be lowered into a large skip and lifted around site. The controls around this activity should be detailed in the site-specific risk assessment.

1.5 Calculating wind load and maximum permissible wind speed

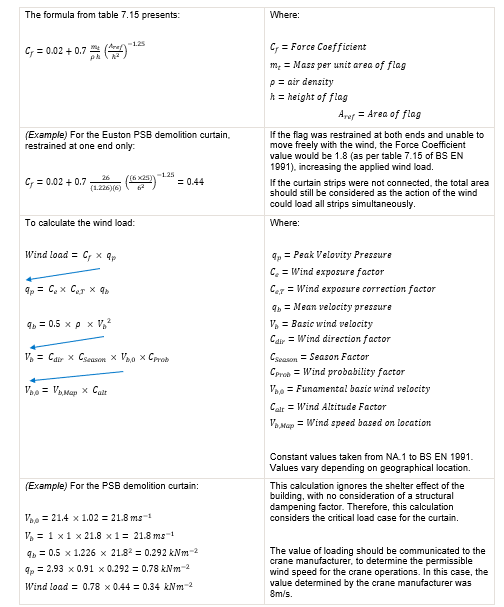

The wind load acting on the demolition curtain is more complex as it is not a rigid body and is able to flex with loading. The curtain can be modelled as a flag, using BS EN 1991-1-4:2005+A1:2010 Actions on Structures[1], establishing a more accurate representation of the applied wind load at the serviceability limit state (SLS).

The calculations below present an example of how to calculate the flag coefficient and wind loading, following page 81 of BS EN 1991.

The flag coefficient should not be used as a drag coefficient (Reynolds number) and wind speed formulas detailed within BS EN 7121: Part 1 Code of practice for safe use of cranes[2] should not be applied. Instead, the crane manufacturer should be consulted within the wind loading calculated above, to provide a permissible wind speed. The method of calculation for the permissible wind speed can vary by crane manufacturer.

2. Exclusion zones

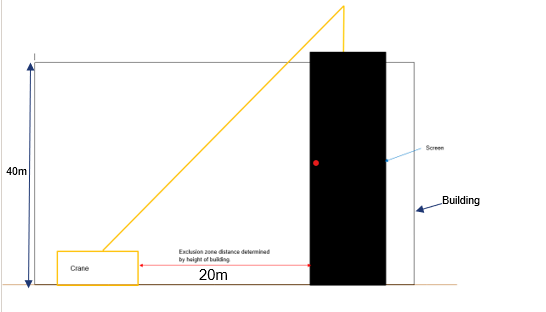

The exclusion zones between the curtain and the crane should be considered and a safe distance maintained. The guidance from the NFDC High Reach Demolition Rig Guidance Notes[3] Section 1.5 Management procedures was adapted to suit for this purpose.

For buildings up to a height of 40m, the working radius of the machine should be a ratio of 2:1, i.e., if the working height is 40m, the front of the crane cab should be at least 20m away measured from the front of crane to the closest edge of the curtain.

The use of remotely operated cranes should be considered when removing the operator well away from the exclusion zone boundary. This was used successfully on the Euston PSB demolition, working alongside Network Rail assets.

3. Accidental loading – effects to consider from falling debris

3.1 Impact of debris

Small debris fly-off and falling items, for example bricks and small elements of concrete, can be expected to fall between the curtain and building, and the curtain does a good job of containing this. However, consideration should be given to what could happen if a larger element were to fall between the building and the curtain.

On the EWC southern section contract, during the use of a demolition curtain, a larger than intended (circa 3m x 5m) 4t concrete section of slab fell between the building and the curtain. As the slab fell and rotated, it snagged the bottom of the curtain. This sent a shock load through the lifting accessories and into the crane, resulting in the failure of one leg of a two-leg chain configuration holding the top beam. The curtain contained the slab within the site/exclusion zone.

3.2 Considerations for dealing with debris

There is a potential for larger elements falling and snagging or impacting on the curtain, thus transferring a shock load from the curtain into the crane. This should be assessed and included in the site-specific risk assessment and design.

It is very likely that the tail end of the curtain will be on the ground at some point of the operation. This will occur because as the building height is reduced, the height of the curtain is also reduced to lessen the exposed surface area of the curtain to wind loading.

When the curtain is lowered, it can fold up on the ground, resulting in the curtain being snagged by falling debris.

Outcomes and learning

Based on the learning from the EWC southern section contract, the recommendations detailed within the three sections of this guidance were implemented on the Euston PSB demolition project.

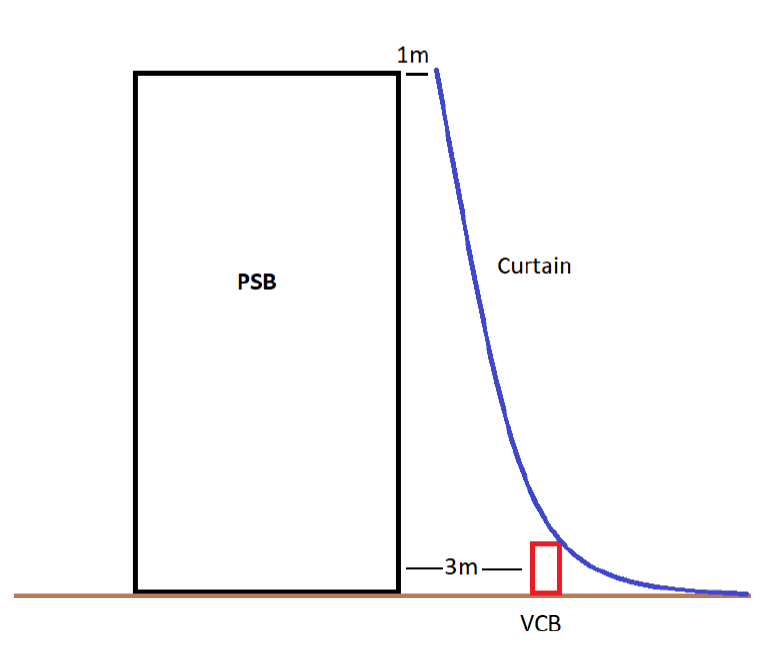

Wind measurements were consistently assessed, exclusion zones configured as per the adapted guidance, and accidental loading issues mitigated by managing the curtain effectively. Figure 3 shows how the curtain was previously being managed. Figures 4 and 5 demonstrate the improvements made during the PSB demolition.

Figures 4 and 5 show the implemented solution which significantly reduced the potential for impact/pinching of the curtain. A row of concrete barriers was placed in front of the curtain to block debris and ensure that the curtain remained swept back. This ensured safe working practice and mitigated any effects of falling debris.

Conclusion and recommendation

The implemented learning on the use of hanging screens and demolition curtains greatly improved the safety and efficiency of demolition operations on EWC South. The key recommendation for others involved in using demolition curtains is that it is imperative that accidental loading, wind speeds and exclusion zones are assessed in detail and the mitigation measures developed and communicated to the operational team.

Existing codes and standards can be applied to the design and operation of demolition curtains, but no formal standard has been published within the UK. The recommendations within this report should be considered when planning future operations, ensuring safety is at the forefront of design and planning.

Acknowledgements

Daniel Brown (CSjv Construction Manager)

Mark Leadbitter (CSjv Senior Engineer)

Rob Wrightam (CSjv Health, Safety and Wellbeing Manager)

Adam Hope (CSjv Lead Appointed Person for Lifting Operations)

Tom Pawson (Costain Designated Individual for Lifting and Scaffolding)

References

[1] European Committee for Standardization. EN 1991-1-4:2005+A Eurocode 1: Actions on structures – Part 1-4: General actions – Wind actions. British Standards Institution; 2010.

[2] British Standards Institution. BS 7121-1:2016 Code of practice for safe use of cranes – General. British Standards Institution; 2016.

[3] NFDC. DRG101:2019. High Reach Demolition Rig Guidance Notes, for demolition machines of 15 metres working height and above. National Federation of Demolition Contractors; 2019.