Reducing the risk of falls from height through design and selection of demolition methodologies

Falls from height are a key risk for traditional top-down demolition activities. The Enabling Works Contract on the southern section of High Speed Two (HS2) includes the demolition of 82 varying types of buildings and 2 gantry cranes. Hence the Enabling Works Contractor explored alternative methods of demolition that could reduce fall from height risk by designing out where possible the installation and periodic removal of scaffolding, the existence of leading edges to lift plant down to the next floor and the use of PASMA towers to sling and support structural elements during demolition. This paper provides an overview of the two of the non-traditional solutions implemented – a demolition curtain in conjunction with a long-reach excavator, and stacked shipping containers to provide encapsulation, in conjunction with the use of a long reach excavator. The paper compares the benefits of traditional versus a less traditional approach.

This paper will be of interest to other projects implementing top-down demolition activities.

Background and industry content

Across the demolition industry, the adoption of traditional top-down demolition methodologies require activities such as the use of access platforms, scaffold erection, scaffold encapsulation and scaffold striking techniques to enable the progression of the demolition works. These activities involve working on leading edges, where there is a risk of falls from height and significantly contribute to high risk profile associated with the work. According to the HSE[1], in Construction there were;

- 40 fatal injuries to workers and four to members of the public in 2019/20

- An average of 37 fatalities to workers and five to members of the public each year over the last five years

- 47% of deaths over the same five-year period were due to falls from height

The Enabling Works Contract (EWC) on the southern section (Area South) is part of High Speed Two (HS2) phase one which includes demolition of buildings within the wider Euston area, utility diversions, environmental and ecological monitoring and a programme of historic environment and archaeological activities, delivered by the Costain Skansja joint venture (CSjv).

In recognition of the known statistics, CSjv and Supply Chain partners committed to exploring non-traditional demolition methodologies during the planning stages of the work, with the aim of eliminating and minimising the risk associated with work activities through methodology design and selection.

Optioneering

Optioneering exercises undertaken as part of the demolition planning stage, resulted in alternative non-traditional demolition methods being identified and executed on site affording us to eliminate risk associated with numerous working at height for activities including:

- the use of access platforms to enable facilitate deconstruction

- erection of scaffold encapsulation to create demolition screens

- scaffold erection to enable the protection of leading edges during demolition works and subsequently striking all scaffold structures.

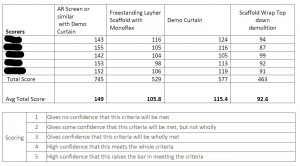

An extract from an example of an optioneering decision log selection review is included in Figure 1, showing combined scoring from team members when considering the methodology for the Euston Power Signal Box demolition.

Traditional vs non-traditional methods

Regents Park Estate

One example of success arose through engagement with the supply chain and the wider demolition industry[2], where the team identified an opportunity to utilise a mechanically suspended demolition curtain to provide demolition screen, in conjunction with the use of a long reach excavator to undertake the demolition elements of the work. Following engagement with demolition industry stakeholders, this method was selected and executed at Regents Park Estate. Regents Park Estate was comprised of numerous high rise multi-wing residential blocks. One block – Silverdale West Wing – was demolished using a traditional top-down demolition approach with scaffold encapsulation due to its proximity to an occupied residential building, however it was possible to utilise the demolition curtain and long reach excavator approach to demolish Silverdale North Wing and Eskdale blocks. The alternative approach enabled the team to significantly reduce work at height activities and impact to neighbours in terms of environmental noise associated with scaffold erection works to achieve scaffold encapsulation and protection of leading edges. A direct comparison between the two methods in terms of health and safety risk, programme, commercial and impact to neighbouring residents; offered benefits and savings, making it the preferred option for both the Site and the Client Team.

The risk hours reduced as a result of utilising the suspended demolition curtain in conjunction with the long reach excavator over the traditional top-down methods were analysed and quantified:

- Silverdale: approximately 18,000 risk hours saved.

- Eskdale: approximately 46,000 risk hours saved.

The reduced risk hours resulted from the elimination of working at height during scaffold loading and unloading, erection and striking of scaffold encapsulation and erection and striking of scaffold structures to protect leading edges and voids as the demolition work progressed.

A detailed paper on the whole Regents Park Estate project is also available An alternative approach to demolition screens at Regent’s Park Estate

Euston Power Signal Box

Another example of success arose after an internal review of demolition innovations within the team, the team identified an opportunity to use stacked shipping containers to provide encapsulation, in conjunction with the use of a long reach excavator to undertake the demolition elements of the work. Following engagement with relevant stakeholders, this method was selected and executed for the demolition of Euston Power Signal Box (PSB). PSB is a multi-story commercial block located 6m from Network Rail assets, a public highway and another HS2 contractor. The alternative approach enabled us to significantly reduce risk associated with working a height as well as reduce the duration of the Network Rail possession required for undertaking work on sensitive elevations of the building. A direct comparison between the original planned method of work (scaffold encapsulation, in conjunction with top-down demolition) and the alternative method of work (stacked shipping containers, in conjunction with a long reach excavator demolition) confirmed the latter approach enabled us to significantly reduce work at height and impact to our neighbours in terms of Network Rail possession time required. Consequently, the benefits of using the stacked shipping containers and long reach demolition approach made it the preferred option for both the Site and the Client Team.

The reduced risk associated with utilising the stacked shipping containers in conjunction with the long reach excavator over the traditional top-down methods were analysed and quantified:

- Reduced risk hours: approximately 2,300 risk hours saved.

Risk hours reduced, resulted from the minimisation of working at height during scaffold loading and unloading, erection and striking of scaffold encapsulation and erection and striking of scaffold structures to protect leading edges and voids as the demolition work progressed.

The opted method of installing stacked shipping containers required approximately 100 working at height risk hours to secure the containers by engaging twist locks and installing marine lashings, thus demonstrating a significant number of risk hour savings.

- Reduced risk of dropped objects: approximately 7,770 less components handled at height.

Opportunity for dropped objects reduced, as a result of the reduced volume of components required to secure the shipping containers, 330 components as opposed to the 8,100 components required to erect the scaffold encapsulation option, thus demonstrating a significant reduction opportunities for dropped objects.

The development and selection of this methodology was a product of the maturity and experience of the team in conducting demolition activity in the area throughout the course of the enabling works contract. It showcases a unique and innovative solution to a complex operation by a high performing team.

The use of shipping containers was the obvious choice for the team in seeking a modular, prefabricated and inherently proprietary system to reduce working at height, working hours, and vehicle movements. They were procured from a container company and delivered routinely on lorries. The bottom container was bolted to a slab that was cast specifically, the containers were mechanically connected, braced and loaded with kentledge in line with the temporary works design to provide a robust screen.

Lessons learned

Each construction or demolition project possess similarities, however each present their own specific challenges depending on the location and sensitivity of the works. This needs to be recognised from the outset.

The positive outcomes as a result of the aforementioned optioneering solutions, highlight the importance of proactively understanding the risk associated with each site and scrutinising proposed work methodologies during the design and planning stages to capitalise on opportunities to agree methods of work which offer the benefit of risk savings.

Recommendations

Challenging current practice and working in collaboration with the Client and Supply Chain to develop innovative and effective ways of deliver the scope of work in the safest and healthiest way possible can optimise safe working.

Points to consider:

- Have you proactively established the risks and specific challenges associated with your work site?

- Have you exhausted opportunities during the design and planning stage to select and agree methods of work which offer the benefit of risk savings?

- Have you shared your innovative solutions?

Acknowledgements

Euston Approaches Demolition Team; Dan Brown, Mark Leadbitter, Taj Daroge, Kearney Sullivan, Ricky Prett and Andy Evans.

The CSjv Engineering Team; Jeff Mahony, Stefano Quintaville, Roy Parr and John Sartin.

John F Hunt Team; Glen Clark, Nick Ward, John Ballatyne, Darren Gell and Davinder Singh Reehal.

References

[1] HSE – Construction Statistics in Great Britain, 2020 [accessed 8 June 2021]

[2] NFDC – National Federation of Demolition Contractors [accessed 8 June 2021]