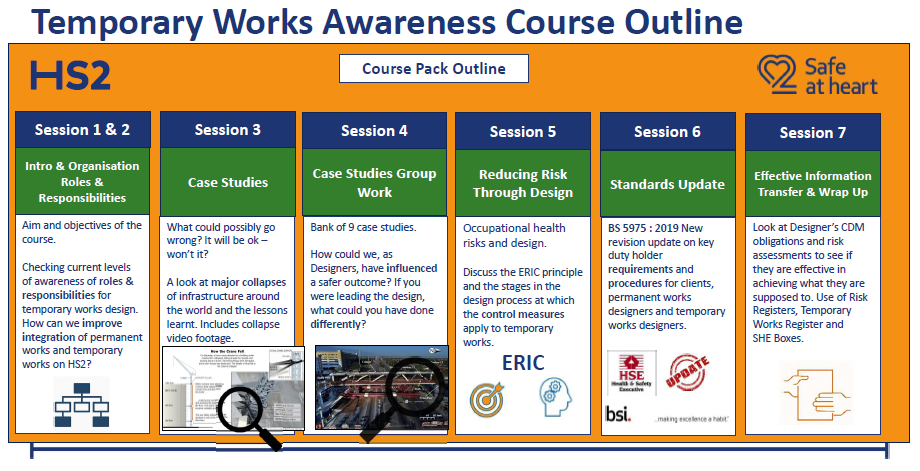

Temporary Works awareness course for designers

All ‘Designer’ roles are required to plan, manage, monitor and coordinate both temporary and permanent works design. CDM says Designers must ensure that they have considered the impact of their design in terms of health and safety during construction work’.

HS2 Ltd developed a temporary works course for its supply chain, for all designers of both their Permanent Works (PW) and Temporary Works (TW) and the co-ordinators of those designs; who manage the interfaces and deliver and construct the final designs.

This course material is shared as a learning legacy for future projects to download and adapt the content to align with their own company design procedures.

Background and industry content

Traditionally, Temporary Works (TW) awareness courses have been developed and given only to TW Co-ordinators (TWC), TW designers and Permanent Works (PW) designers that specialise in design.

TW awareness training has not been aimed at all PW designers who are responsible under CDM for addressing the buildability of the PW and who must identify and make provision for any temporary works or temporary loading conditions required by their design and their assumed methods of construction; with those assumptions then being communicated onwards for coordination by the TWC to the TW designers and finally management by those constructing the works. This course attempts to bridge that training gap and recognises that sometimes the ‘best’ temporary works are ‘no’ temporary works.

Originally launched across the HS2 supply chains in May 2020, the course has been developed by the HS2 SSHELT (Safety, Security, Health, Environment Leadership Team) Temporary Works Risk Working Group under the HS2 ‘Safe at heart’ commitment and in collaboration with the HS2 supply chain and the external industry temporary works specialists TWf (Temporary Works Forum).

More background can be found from the links containing the recording of the course launch and the accompanying presentation.

Course Structure

The course is underpinned by the requirements and recommendations from the Industry Codes of Practice (CoPs) for temporary works design and permanent works design and their interface. These CoPs are referenced and scrutinised throughout the course, particularly when looking at the case study material.

To paraphrase CDM[1] and BS 5975[2]:

“you must ensure that there is appropriate process for designer coordination and co-operation when there is interaction between temporary works and permanent works”

” Designers must ensure that they have considered the impact of their design in terms of health and safety during construction work”

“Permanent works designers should provide relevant information on their designs to inform the temporary works designers”

“Permanent works designers should address the buildability of the permanent works and identify, and make provision for, any temporary works and temporary conditions required by their design and their assumed method of construction”

These statements in CDM[1] have enabled the industry temporary works Codes of Practice to recently expand on the key duties of all parties with respect to the management of temporary works and introduce procedures specific to Clients, Designers, Contractors and Sub-contractors and be more specific about how this can be achieved through the new revisions of BS 5975 Code of Practice for temporary works procedures[2] and the two PAS documents: PAS 8811 Temporary Works – Major Infrastructure client procedures – Code of practice[3] and PAS 8812 Temporary works- Application of European standards in design-guide[4], both sponsored by HS2. Sessions 1 & 2 of the course cover these responsibilities in detail.

Aims and objectives

The real AIM of the course is to provide attendees with an awareness of how these duties of the permanent works designer and temporary works designer can be carried out safely within the layers of interface for interdependent temporary works and permanent works design. Giving a clear message of the need for compatibility and the integration of permanent works and temporary works at the earliest possible stage of design. This will, in turn, aid the constructability and to ensure that any residual risks, designer constraints/methodology assumptions and assumed construction sequences (including known unstable conditions) are clearly communicated to those that need it – those tasked with constructing and designing the work.

The case studies section in sessions 3 and 4 highlight the important message around assessing the permanent works in a temporary state, the temporary stability of those works and the induced temporary loads during construction. And what can happen if that doesn’t happen and indeed what happens when we overthink and over engineer and create very robust solutions and go too far in our CDM obligations assuming and stating temporary parameters. The video case studies are very powerful and reinforce the message.

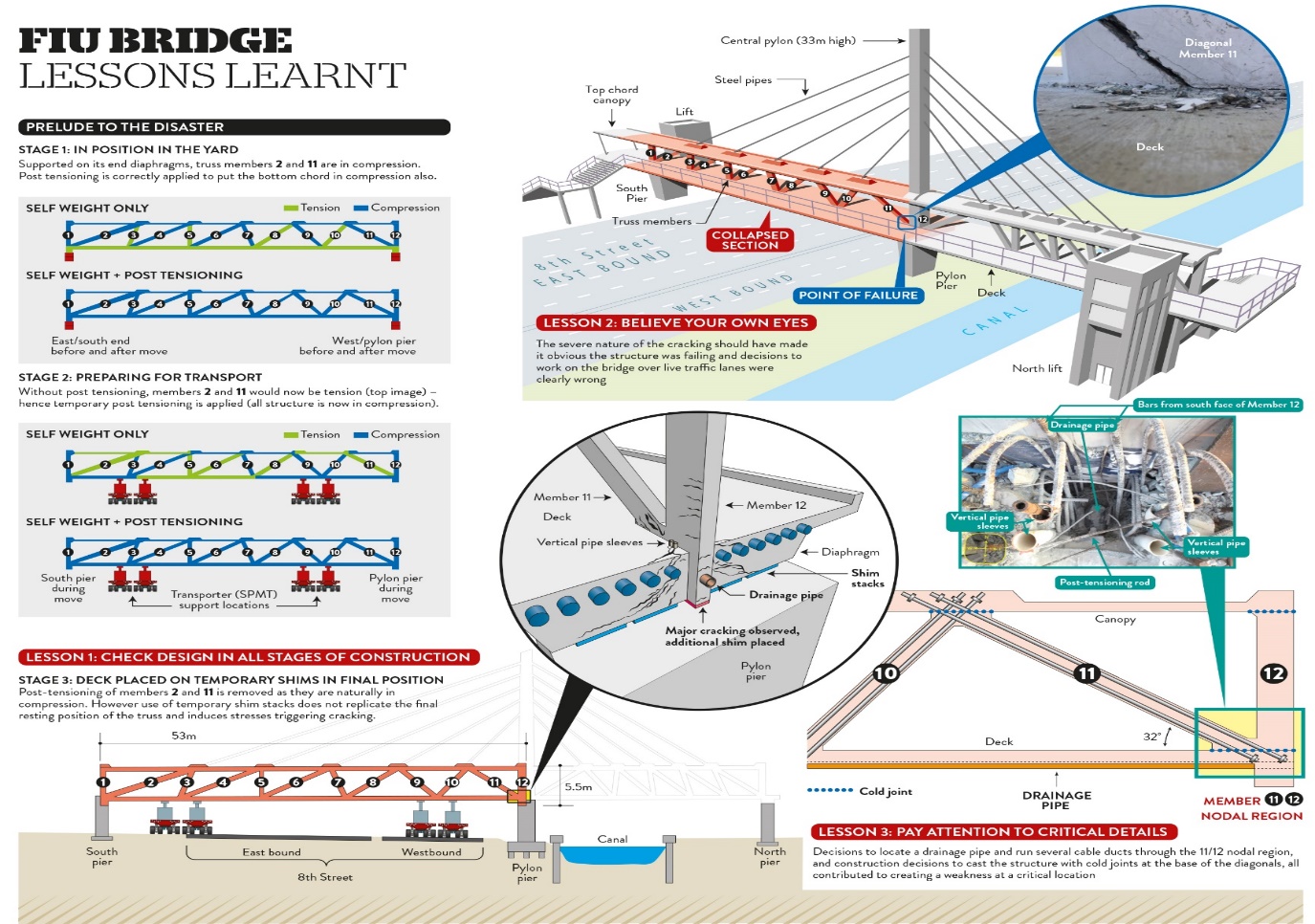

Florida International University (FIU) Fatal Bridge Collapse

One of the case studies highlights the importance of checking a design for all stages of construction – including the temporary stage when being supported in a temporary manner, as in the situation encountered with the Florida International University (FIU) Fatal Bridge Collapse in Miami on March 15th 2018. Design calculation errors, failures by the independent design checker, client, contractor and on-site construction supervisor all contributed to the disaster and has led to a number of recommendations by UK engineering safety body SCOSS (Standing Committee on Structural Safety)[5].

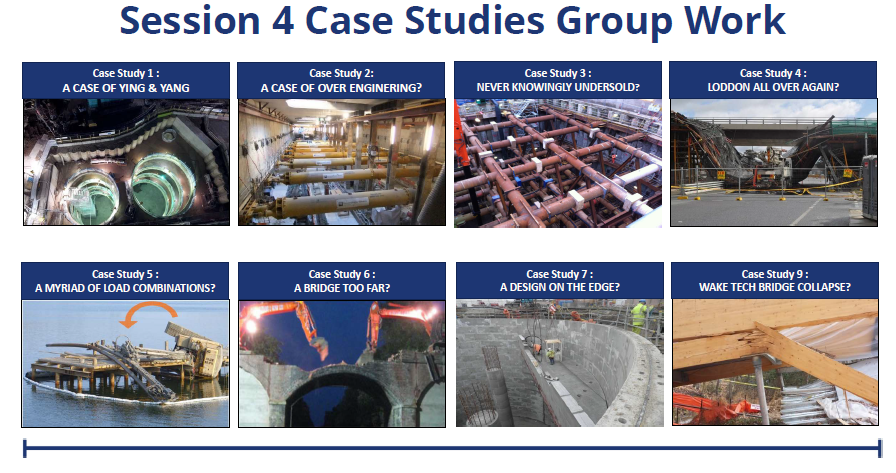

Case Studies Group Work

Sessions 3 & 4 are the real hub of the course and shares for the first time, historic case studies that have been provided by the construction industry, with the intention of drawing out the wider issues around the critical interfaces between PW and TW design for debate amongst the delegates and to provide learning and information that can then be incorporated into Designers procedures for temporary works.

Session 3 takes the attendees through a Worldwide journey of some of the major collapses of infrastructure that have occurred, with the mantra:

“What could possibly go wrong? It will be ok-won’t it?”

How many times have we heard that statement in some form, particularly after someone has attracted the designer title under CDM by making an ad-hoc design change on site without referring back to the designer or a designer constraining a design with “difficult bits by others” statements on drawings?

These are failures that could be attributed to poor design or a lack of design or a lack of coordination and integration of permanent works and temporary works, resulting in unstable temporary conditions. They contain important messages around the temporary stability of permanent works and the induced temporary loading of permanent works during construction. Designing for the “temporary effects”

Course materials can be downloaded from the  portal

portal

Lessons learned and successes

A one-day Pilot of the Course was carried out with senior PW and TW designers and TWCs from across the HS2 Programme. The feedback and learning from that group have been incorporated into the latest downloadable course material. The course has been very well received across the HS2 Supply Chain with upwards of 500 delegates having already being trained to date and with further and wider training sessions planned for 2021. The course material is in a constant state of update with new case studies and material being added by the supply chain all the time to enhance and augment their own established temporary works training awareness modules and roll out.

Recommendations

The task of the reader, with a vested interest in either PW or TW design and their coordination, is to use the course material and develop it further with more case studies and then align it to their own design procedures and finally deliver it across their respective design houses and companies and the wider design communities.

The ultimate goal is to ensure that designers give consideration to construction methodology so that the PW can be optimised and assessed for any temporary conditions and that any required TW can then be minimised and communicated through the coordination of that interface between PW and TW designers. Ultimately, these considerations could be an addition to the traditional project temporary works register in the form of a combined PW and TW register with the risks assessed and managed.

Acknowledgements

I would like to thank my fellow course presenters Tim Hackett Rendel Ltd and Tim Lohman Wentworth House Partnership for their time, enthusiasm and knowledge.

All of this work was steered by the SSHELT Working Group leads Steve Fink HS2 and Chris Evans Volker Fitzpatrick.

My thanks also go to the SSHELT Working Group members and their respective companies: John Holden HS2, John Gregory BBV JV, Alan Phillips Kier, Melodie Gilbert Align JV, Christopher Fesq Align JV, Kameron Lee Align JV, Scott Wilson LMJV, Dominic Pearse Jacobs, Andre Stockbridge CS JV, Matt Barnes Skanska UK and Peter Johns Skanska UK.

References

[1] Construction (Design and Management) Regulations 2015 (CDM)

[2] BS 5975:2019 Code of practice for temporary works procedures and the permissible stress design of falsework

[3] PAS 8811:2017 Temporary works – Major infrastructure client procedures – Code of practice

[4] PAS 8812:2016 Temporary works – Application of European Standards in design – Guide

[5] The Standing Committee on Structural safety SCOSS and CROSS Alert Dec 2020 LESSONS LEARNT FROM THE 2018 FLORIDA BRIDGE COLLAPSE DURING CONSTRUCTION.